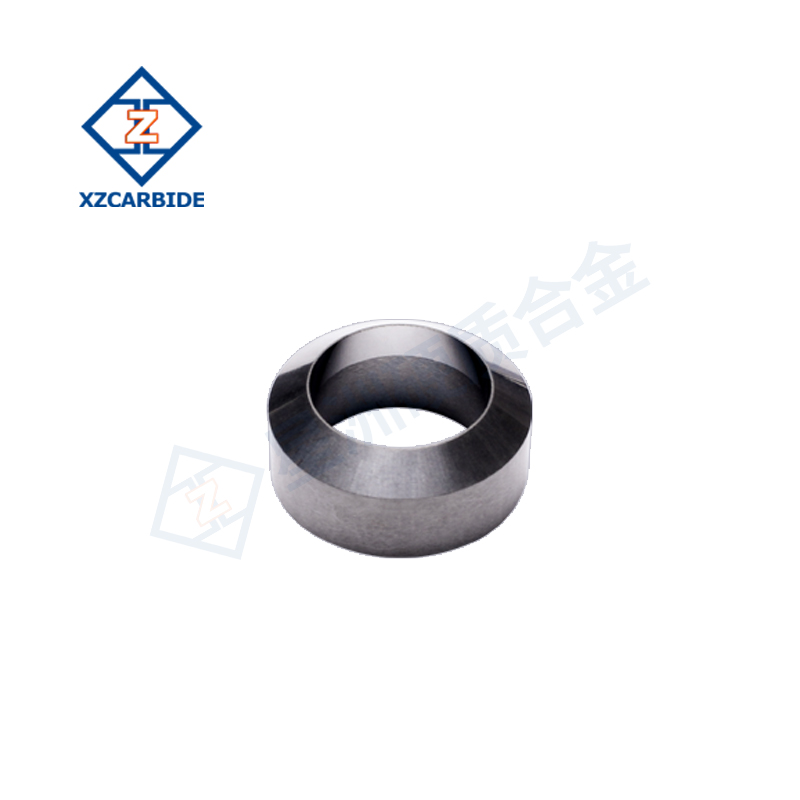

Main Features

- Excellent wear resistance: high hardness cemented carbide can effectively resist abrasion and provide a service life up to 10 times longer than that of steel bushings, which is suitable for long-time and high-frequency operation.

- Superior corrosion resistance: Able to resist the erosion of acid, alkali and other chemical media, which can adapt to diverse harsh industrial environments.

- High strength and stability: Provide reliable structural support to ensure the safe operation of the equipment in complex working conditions, suitable for bearing high lateral load conditions.

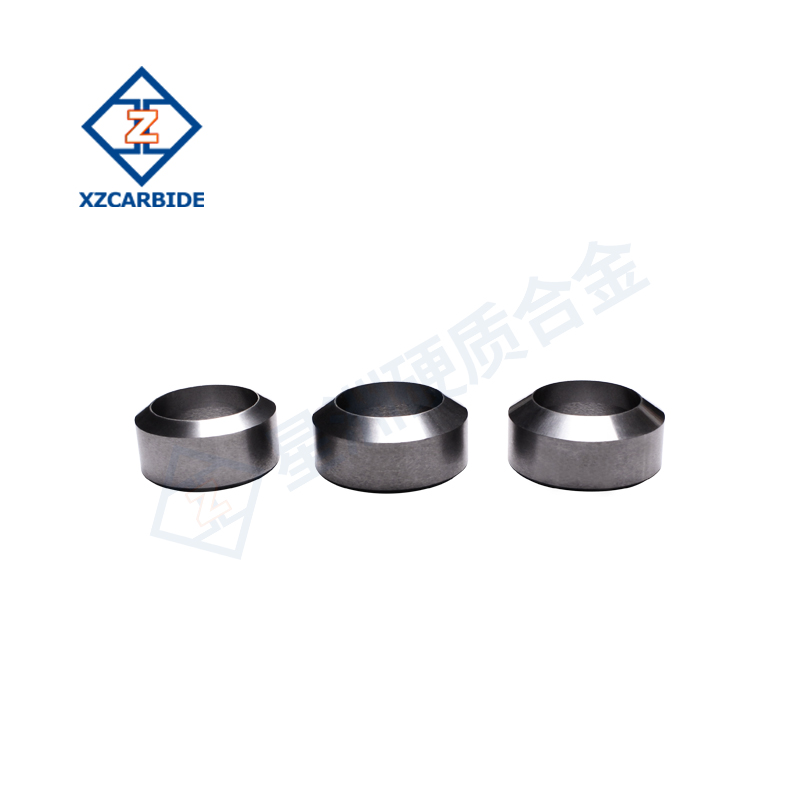

Technical Parameters

| Material | Tungsten carbide |

| Composition | WC and Co, specific ratios based on demand |

| Hardness | HRA 88-94 |

| Density | 14.5-15.0 g/cm³ |

| Bending Strength | Up to 2000 MPa or more depending on material |

| Size | Customized according to customer needs |

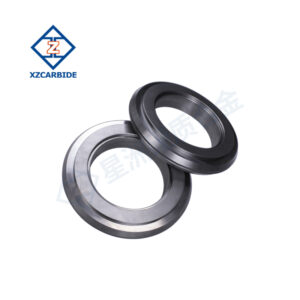

Applications

Cemented carbide wear resistant shaft sleeve is widely used in different industrial fields that require high strength, high abrasion resistance and corrosion resistance, including but not limited to:

- Oil and gas: Drilling equipment, oil extraction machinery, oil and gas transportation pipeline

- Chemical industry: Pumps, valves, agitators in corrosive media

- Metallurgy: Bearings, seals, transmission parts in high temperature and heavy load environments.

- Mining: Crusher, ball mill, roadheader and other heavy equipment shaft sleeve

- Machinery manufacturing: CNC machine tools, precision machinery and other equipment that require high precision and long life shaft sleeve

Reviews

There are no reviews yet.