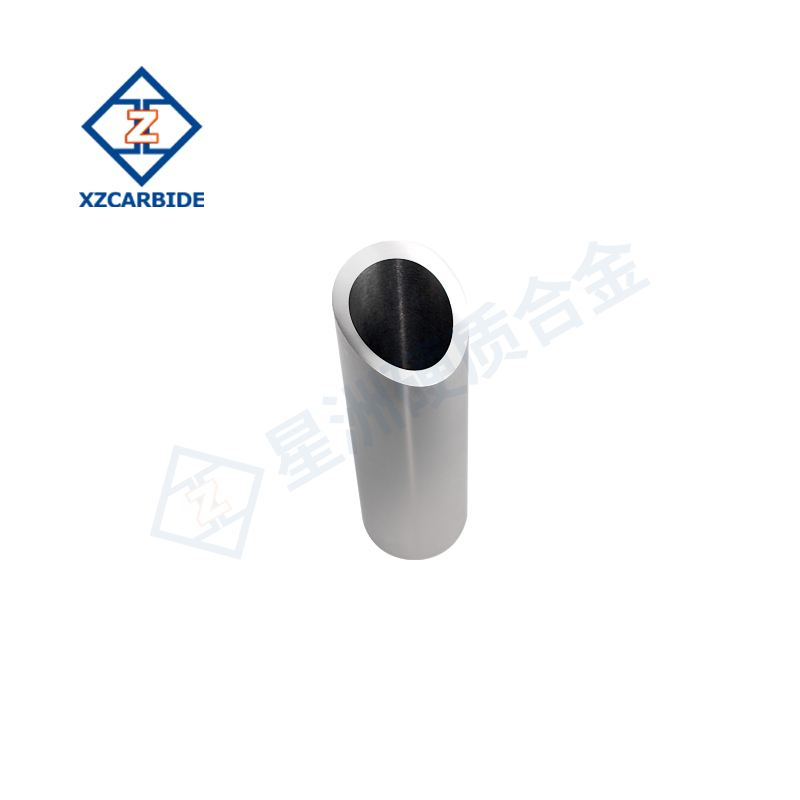

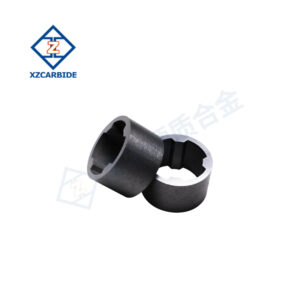

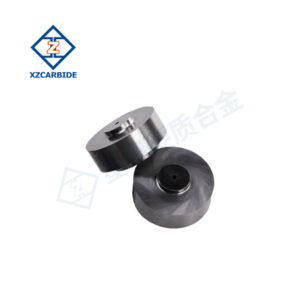

Basic Information

| Material | Tungsten carbide |

| Common Grades | YG series |

| Hardness | HRA 85-92 |

| Dimension | Upon request |

| Features | High hardness Superior wear resistance Strong stability High corrosion resistance |

| Adavantages | High quality materials Reduced maintenance costs Increased production efficiency Customized services |

| Applications | Automotive, aerospace, industrial equipment and mining machinery |

Use and Maintenance

The following points should be noted when using the carbide sleeve:

- Correct installation: Make sure the carbide sleeve is correctly installed in the equipment to avoid damage caused by improper installation.

- Regular inspection: Regularly check the wear and tear of the carbide sleeve and replace the badly worn sleeve in time.

- Maintenance: Periodically maintain the equipment, keep it clean and lubricated to prolong the service life of the carbide sleeve.

Common Used Grades

| Grade | Density (g/cm3) | Hradness (HRA) | TRS (MPa) | Performance & Recommended Application |

| YG6A | 14.85 | 92.5 | 2000 | Fine grain alloy, good wear resistance, it is suitable for manufacturing forming cutter, wear-resistant parts. |

| YG8 | 14.7 | 89.8 | 2800 | High bending strength, wear resistance lower than YG6A, fit for manufacturing forming cutter, wear-resistance part etc. |

| YG11 | 14.4 | 88.5 | 2900 | |

| YG15 | 14.0 | 87 | 3000 | Used for manufacturing punching dies, wear-resistant parts. |

| YG20 | 13.5 | 85.5 | 2800 | High bending strength, suitable for manufacturing progressive dies and other punching dies. |

| YG13X | 14.2 | 90 | 3200 |

Reviews

There are no reviews yet.