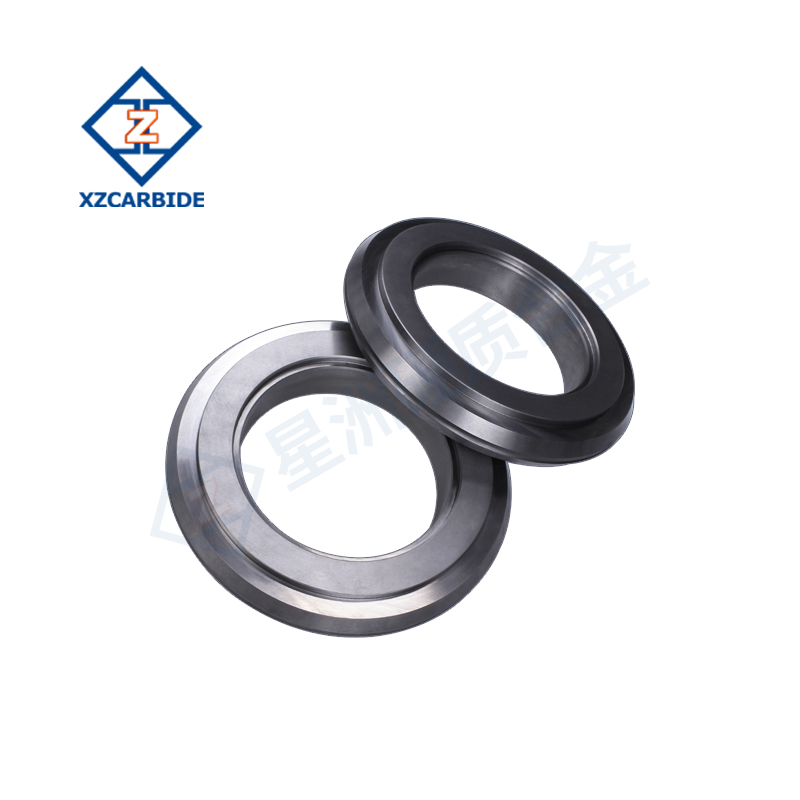

Product Parameters

| Material | Tungsten carbide |

| Hardness | Above HRA 80 |

| Dimension | Upon request |

| Coating | Optional coatings, such as chrome or tungsten carbide powder, are available, with coating thicknesses typically ranging from 0.06 to 0.08 mm. |

Product Characteristics

- High Hardness: The hardness of tungsten carbide is second only to diamond, which can effectively resist abrasion.

- High Wear Resistance: Maintain long service life in high load and high speed rolling process.

- High Temperature Resistance: Suitable for high temperature working environment, withstanding temperatures up to 800℃.

- Corrosion Resistance: Excellent stability to most chemical media.

- Impact Resistance: Keep the structure intact and not easy to rupture under impact loads.

- Customized Service: Customized rollers with different specifications and shapes according to customers’ needs.

Application Fields

- Metal Processing: Used in cold rolling, hot rolling, forging and other processes to improve the surface quality and processing accuracy of metal materials.

- Wire production: Key component in wire drawing machines, stranding machines and other equipment to ensure the uniformity and consistency of the wire.

- Paper-making Machinery: Improve the strength and stability of cardboard in corrugated cardboard production line.

Common Used Grades and Their Performance

| Grade | Density (g/cm3) | Hardness (HRA) | Performance |

| YG6 | 14.8 | 89 | High hardness and good abrasion resistance, suitable for moderately corrosive environments. |

| YG8 | 14.7 | 91 | Excellent integrated performance for most corrosive and highly abrasive environments. |

| YG15 | 14.2 | 92 | Higher wear and impact resistance for extreme working conditions. |

Reviews

There are no reviews yet.