Technical Parameter

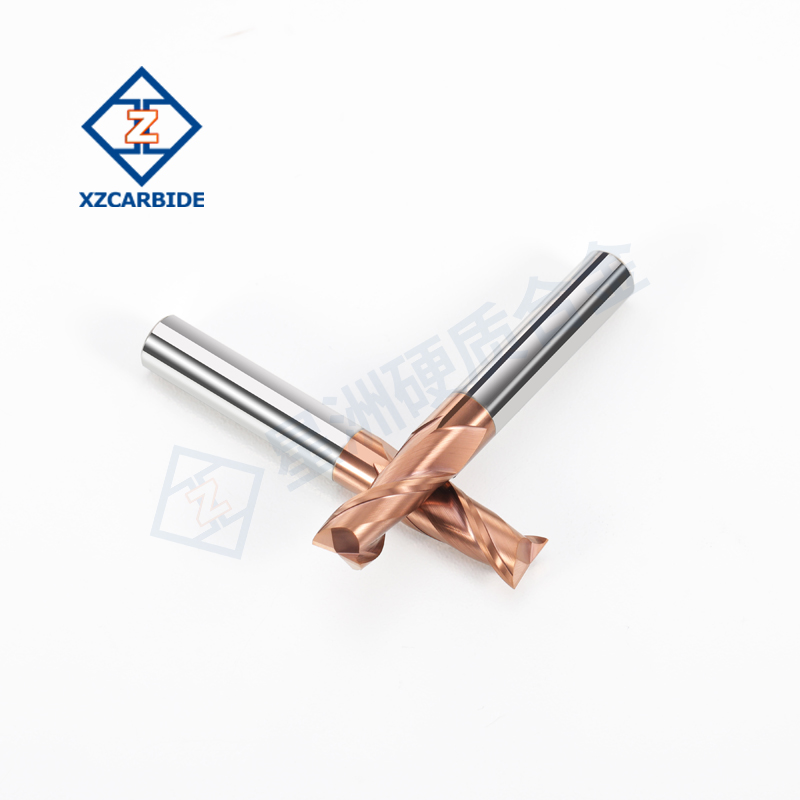

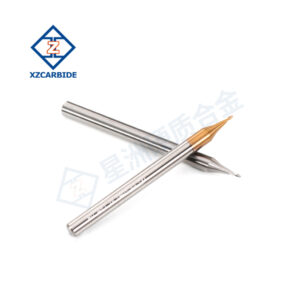

| Material | HSS or carbide |

| Diameter Range | Common diameters range from 1 to 20 mm |

| Length Range | Scaled length options based on diameter |

| Number of Blades | Typically multi-flute design to improve cutting efficiency and surface quality |

| Customized Service | Customization services are available to meet special processing needs, including non-standard sizes and special coatings |

Product Features

- High-precision machining: The flat and straight end enables precise vertical and horizontal cutting to ensure machining accuracy.

- Various specifications: A variety of diameter and length specifications are available to meet different processing needs.

- High-quality material: Made of high-quality HSS or cemented carbide for good wear resistance and long service life.

- Coating options: Provide various coating options, such as TiN, TiAlN, AlTiN, DLC, etc., to enhance tool performance.

Applications

Mainly used for machining grooves, steps and various mutually perpendicular planes, especially excellent in machining deep grooves in case parts made of steel and cast iron.

- Mold machining: Used for milling cavities and cores of molds.

- Machining: For machining flat surfaces and contours on machine parts.

- Aerospace: Suitable for milling of high-precision parts.

- General machining: Applicable to the machining of various mechanical parts.

Reviews

There are no reviews yet.