Overview

Carbide materials are made from tungsten carbide and metal binder by powder metallurgical process. Due to its excellent hardness, wear resistance and thermal stability, carbide occupies an important place in industry and has become an indispensable material for industrial manufacturing. This material plays a key role in applications such as cutting tools, mining tools, and mold making.

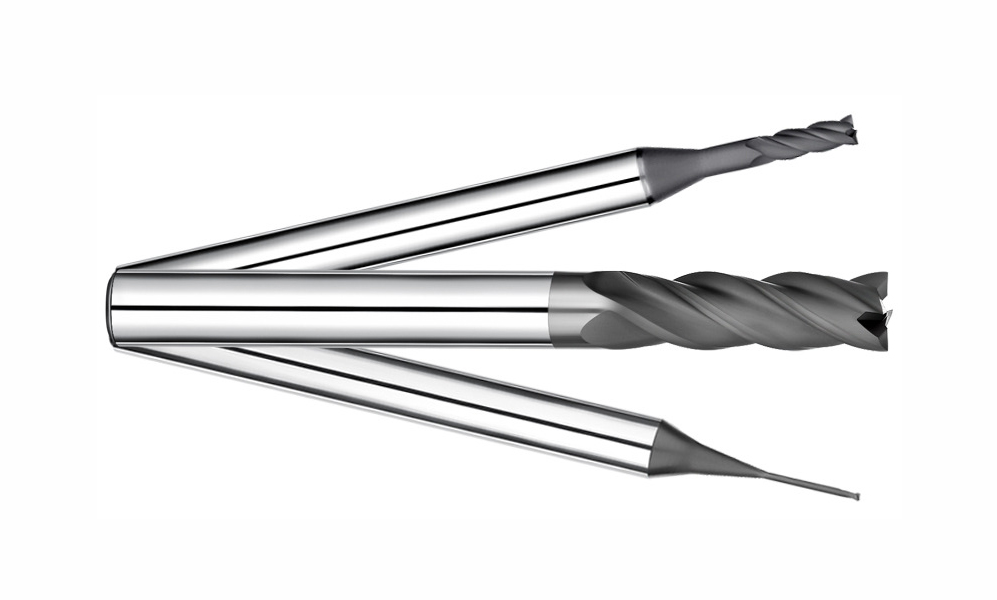

Cutting tools, one of the most widespread applications of carbide, are the core equipment of the manufacturing and processing industry. They are used in various machining operations such as turning, milling, drilling and cutting. Their presence significantly improves machining efficiency and product quality. High quality carbide cutting tools not only extend tool life but also reduce production costs.

Understanding how to make high-performance carbide cutting tools is important for improving the overall level of manufacturing. In this paper, we will discuss in detail the key factors for making quality carbide cutting tools, including material selection, manufacturing process, quality control and something else.

Material Selection for Carbide Cutting Tools

Composition of Carbide

Cemented carbide, usually consisting of tungsten carbide (WC) and a metallic binder (e.g. cobalt), is a composite material made by a powder metallurgical process. Tungsten carbide gives the material extremely high hardness and wear resistance, while cobalt provides the necessary toughness and impact resistance as a binder. This combination enables tungsten carbide to maintain excellent performance at high temperatures and pressures, making it an ideal material for the manufacture of cutting tools.

Tungsten Carbide (WC): the main component, providing hardness and wear resistance

Cobalt (Co): the binder, providing toughness and impact resistance.

Impact of Material Selection on Cutting Tool Properties

Material selection directly affects the performance of cemented carbide cutting tools, including hardness, wear resistance, impact resistance and heat resistance. Cemented carbide materials with different compositions and ratios will vary in these properties, thus affecting the service life and machining quality of cutting tools.

Hardness: High tungsten carbide content increases hardness and wear resistance, but decreases toughness.

Toughness: High cobalt content increases toughness and impact resistance, but decreases hardness and wear resistance.

Heat resistance: Proper composition ratio can improve heat resistance, so that the tool maintains stable performance in high-temperature cutting.

Choosing the right carbide material requires comprehensive consideration of specific application scenarios, processing materials and processing conditions. For example, machining that requires high precision and finish requires high hardness and wear resistance, while overloading cutting requires high toughness and impact resistance.

Pros and Cons of Different Carbide Grades

Different grades of cemented carbide have different composition ratios and properties, and a comparison of common cemented carbide grades is as follows:

| Grade | Strength | Weakness |

| YG6 (WC 94%, Co 6%) | High hardness and wear resistance for fine cutting and light load machining. | Lower toughness, not suitable for overloading cutting. |

| YG8 (WC 92%, Co 8%) | Good balance of hardness and toughness for medium load cutting. | Slightly weaker in high hardness material machining. |

| YG15 (WC 85%, Co 15%) | High toughness and impact resistance for overloading cutting and intermittent machining. | Lower hardness and wear resistance, not suitable for high-precision machining. |

| YG20 (WC 80%, Co 20%) | Very high toughness and impact resistance for the heaviest duty cutting and hammering. | Lower hardness and wear resistance, not suitable for detailed machining. |

| YW1 (WC+TiC+TaC+Co) | High hardness and wear resistance for cutting stainless steel and high temperature alloys. | Lower toughness, need to be used under stable processing conditions. |

| YN10 (WC+Ni) | High corrosion resistance, suitable for cutting in high humidity or corrosive environments. | The hardness is slightly lower than that of cobalt-bonded cemented carbides. |

| YT15 (WC+TiC+Co) | High hardness and wear resistance for cutting cast iron and non-ferrous metals. | Lower toughness, not suitable for machining with high impact loads. |

By choosing the right grade of cemented carbide, the performance of cutting tools can be optimized to improve machining efficiency and product quality.

Manufacturing Technology for Carbide Cutting Tools

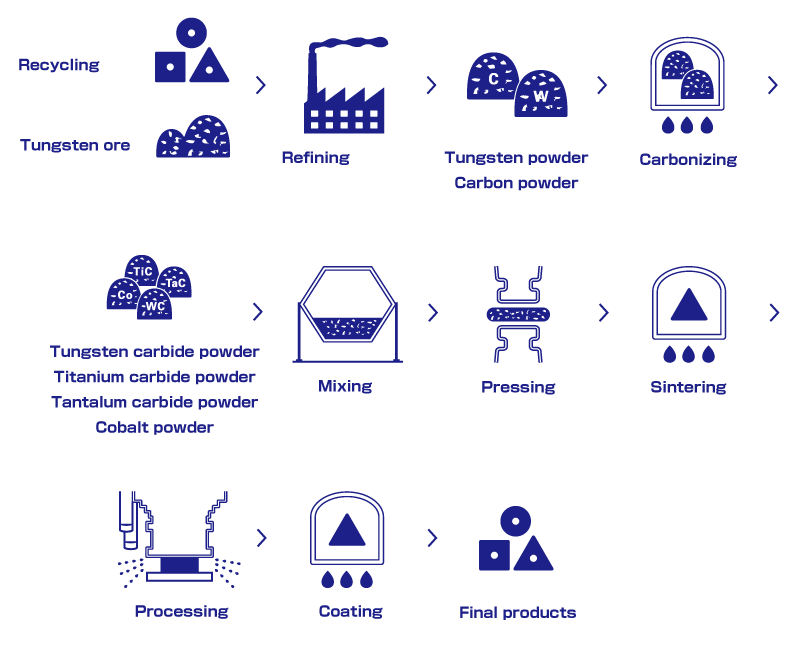

The manufacturing process for cemented carbide cutting tools involves a number of key steps, including powder metallurgy technology, sintering processes and finishing. Each step has a significant impact on the quality and performance of the final product.

Powder metallurgy

Powder Mixing: Tungsten carbide and cobalt powders are mixed in a ratio to ensure a uniform distribution of components.

Addition of Additives: Waxes or other organic substances are added as molding aids to improve the flowability and pressing properties of the powders.

Press Molding

Mold Design: The mold is designed according to the shape and size of the cutting tool.

Pressing Technology: The mixed powder is loaded into the mold, and the powder is pressed into blanks by cold or hot pressing methods.

Sintering Process

Pre-sintering: Organic molding aids are removed from the powder at low temperatures to prevent defects during sintering.

Sintering: Performed at high temperatures (typically 1300°C to 1600°C) and for the appropriate time (a few hours) to bond the powder particles together to form a dense cemented carbide.

Sintering Environment: Carried out in a vacuum or in a protective atmosphere (e.g. hydrogen, nitrogen) to prevent oxidation and carbide decomposition.

Hot Isostatic Pressing (HIP) Treatment: Elimination of pores generated during sintering under high temperature and pressure to further improve the density and mechanical properties.

Finishing

Machining: Rough machining of the sintered blank using turning, milling and other methods to initially form the shape of the cutting tool. Using grinding, polishing and other methods of finishing the cutting tool to ensure its dimensional accuracy and surface quality.

Surface Treatment: Coating treatment is carried out on the surface of the cutting tool, such as PVD, CVD to enhance the tool’s wear resistance and heat resistance. Polishing treatment on the tool surface to reduce surface roughness and improve cutting performance.

Quality Control

Raw Material Testing: Strictly analyze the composition of tungsten carbide and cobalt powders to ensure that their purity and proportion meet the requirements. Test the particle size distribution of the powders to ensure that they are suitable for pressing and sintering processes.

Manufacturing Process Control: Detect the density of pressed blanks to ensure their uniformity and denseness. Real-time monitoring of sintering temperature and time to ensure a stable and reliable sintering process.

Finished Product Inspection

Hardness Test: Check the hardness of cutting tools to ensure that they meet the design requirements.

Wear-resistance Test: Measure the wear-resistance of the cutting tools through simulated cutting tests to evaluate their service life.

Dimensional Accuracy Test: Adopt precision measuring instruments to test the size and shape of the tools to ensure that they meet the tolerance requirements.

Manufacturing Processes for Carbide Cutting Tools

The Impact of Design on Performance

The design of a cutting tool plays a key role in its performance. Design parameters such as geometry, tool angle, cutting edge shape directly affect the cutting efficiency, durability and machining accuracy of the tool.

Good design can:

Increase material removal rate: by optimizing cutting edge angle and geometry, material can be removed more efficiently and cutting forces can be reduced.

Extend tool life: proper design can extend tool life by dispersing stress and reducing wear.

Improve machining accuracy: precise tool geometry and angle settings can improve the finish and accuracy of machined surfaces.

How to Optimize Design

CAD Design

Accurate design: Optimize tool angles and cutting edge shapes to ensure design accuracy and manufacturability.

Rapid iteration: Create and modify tool designs quickly, making multiple iterations to find the best design.

Simulation Techniques

Finite element analysis (FEA): Modeling stress distribution, heat generation, and chip flow during the cutting process to predict how the tool will perform in real-world use and to optimize the design.

Computational fluid dynamics (CFD): Simulate the cutting fluid flow and cooling effect, optimize the cutting fluid channel design, improve the cooling efficiency and cutting performance.

Common Problems and Solutions in Production

| Problems | Solutions |

| Pores, cracks and uneven composition | 1. Select high purity tungsten carbide powder and cobalt powder, use efficient mixing equipment and methods to ensure uniform mixing of tungsten carbide and cobalt powder. 2. Precisely control the sintering temperature and time, optimize the sintering curve, and reduce the pores and cracks inside the material. |

| High hardness and brittleness | 1. Adopt advanced processing technology, such as laser and EDM. 2. Coat the surface with high hardness and wear-resistant coatings to extend tool life. 3. Select appropriate cutting speed and feed to reduce cutting force and heat generation to avoid tool chipping and material damage. 4. Use efficient cooling and lubrication methods, such as high-pressure coolant and cold air injection, to reduce the temperature of the machining area, minimize thermal deformation and tool wear. |

In addition, feedback from practical applications is critical to the continuous improvement of cutting tools. By collecting and analyzing in-use data and feedback, design deficiencies can be identified and targeted for optimization.

Application of Carbide Cutting Tools

Carbide cutting tools are widely used in various manufacturing and machining industries due to their advantages. Following are the major applications of carbide cutting tools in different fields:

| Field | Requirements | Applicaions |

| Aerospace | High temperature stability, wear resistance | High-temperature alloys and titanium alloy parts, such as aero-engine components, fuselage structural parts, etc. |

| Automobile Manufacturing | High machining efficiency, high precision | Engine parts, drivetrain and body parts such as cylinder heads, crankshafts and gears. |

| Mold | High precision, wear resistance | Precision mold parts, such as injection molds, die-casting molds and stamping dies. |

| Energy Facilities | High abrasion and impact resistance | Energy equipment parts such as oil drill bits, turbine blades and wind turbine components. |

Conclusion

The discussion in this paper has provided insight into the key elements of making quality carbide cutting tools. Continuous innovation and constant improvement are important to ensure the performance and quality of cutting tools. In the future, with the continuous development and application of advanced manufacturing technologies, we are confident to see more high-performance and high-precision tools contributing more to the progress and development of the manufacturing industry.

Reasons Why Choose Xingzhou

- High quality materials and techniques: High quality cemented carbide materials combined with advanced manufacturing techniques. We ensure that our products have excellent hard performance and can maintain stable performance under various working conditions.

- Professional technical team: A professional team specializing in product design, manufacturing and optimization can provide high-quality customized products.

- Strict quality control: Strict implementation of ISO quality management system. Comprehensive monitoring and management of the production process ensures that each cutting tool meets high quality standards.

- Customized service: Provide the best solution according to customer’s needs and applications, including tool shape, edge type, coating treatment, etc.

- Continuous technological innovation: Continuously investing in R&D and technological innovation, focusing on the latest trends and technological breakthroughs in the industry to provide customers with a competitive advantage.