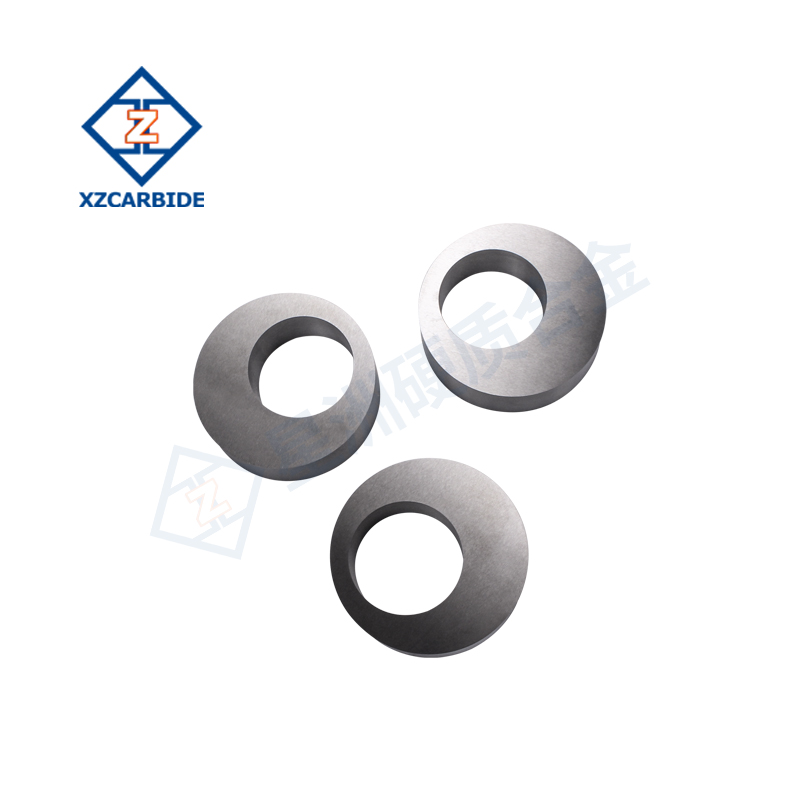

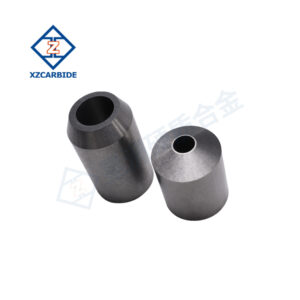

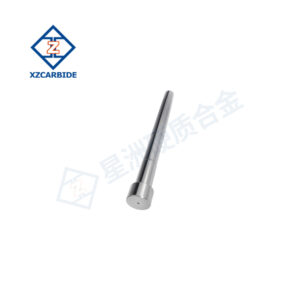

Product Features

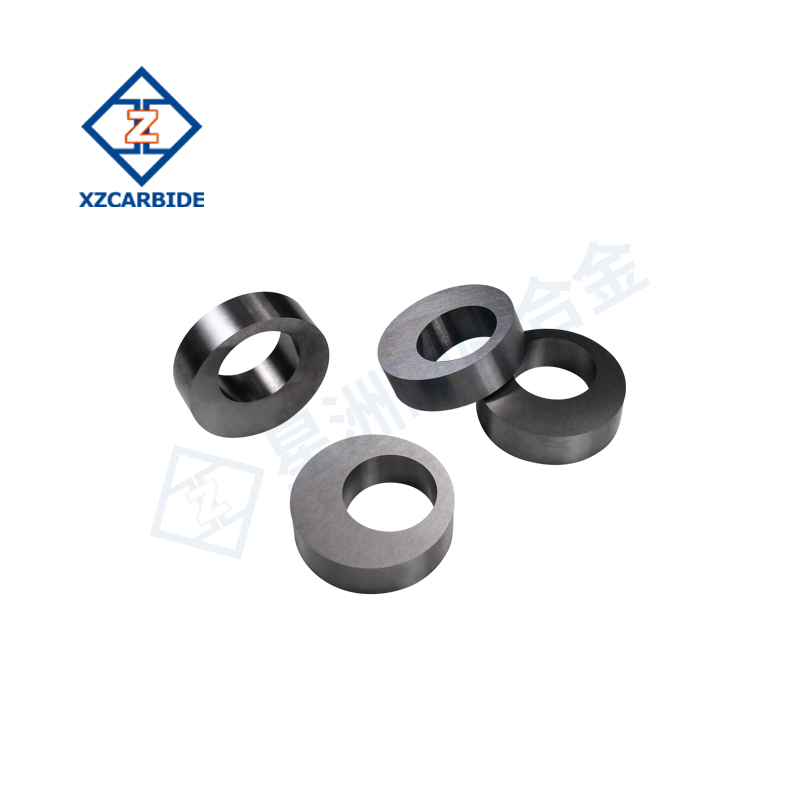

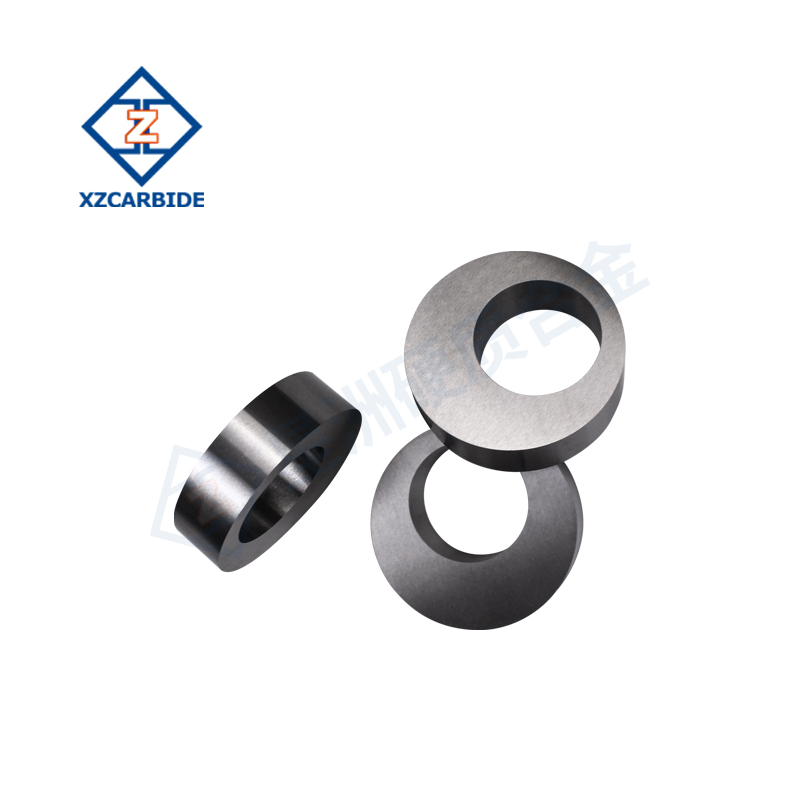

- Customized design: According to customer requirements, design and manufacture molds with specific shapes and sizes to meet the production requirements of different products.

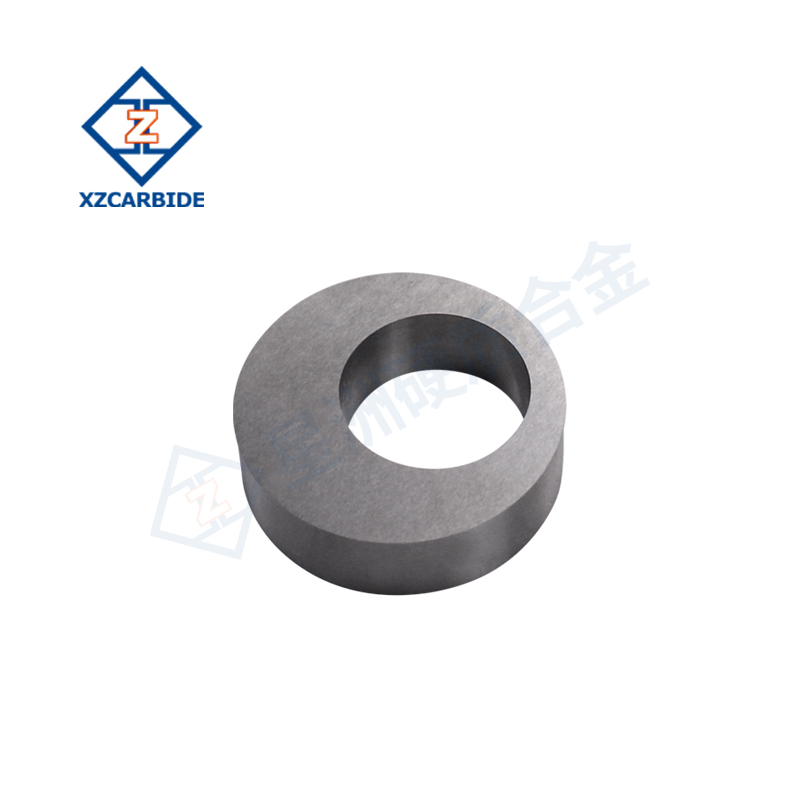

- High-precision processing: Adopt advanced CNC machine tools and precision grinding process to ensure the high precision and consistency of the molds.

- Strong durability: Selection of high quality materials to manufacture the molds and special treatment to improve the hardness and abrasion resistance of the molds to prolong the service life.

- High production efficiency: Irregular shaped drawing die can complete the stretch molding process quickly and accurately, improve production efficiency and reduce production cost.

- Widely used: Suitable for shaped metal stretching processing in automobile parts, electronic products, aerospace and engineering machinery.

Common Used Grades

Grade | Composition | Density (g/cm3) | Hardness (HRA) | Flexural Strength (MPa) | Properties |

YG6 | 94% WC, 6% Co | 14.6 | 89 | 1520 | High hardness and good wear resistance , suitable for general wear and impact applications. |

YG8 | 92% WC, 8% Co | 14.5 | 88.5 | 1600 | High hardness with impact resistance , suitable for medium impact and wear conditions. |

YG15 | 85% WC, 15% Co | 14.0 | 86 | 2400 | High flexural strength and impact toughness , ideal for high impact and wear environments. |

YNi8 | 92% WC, 8% Ni | 14.7 | 88.5 | 1500 | Good corrosion resistance and toughness , suitable for chemical and corrosive media environments. |

YG20 | 80% WC, 20% Co | 14.0 | 84 | 2800 | Extremely high flexural strength and toughness , ideal for high impact and high wear environments. |

Customized Services

We provide customized irregular shaped drawing die solutions based on customer needs. Whether customizing a single piece or producing large quantities, we can provide you with an efficient and reliable tooling solution. Please contact us for more details and customization options.

Reviews

There are no reviews yet.