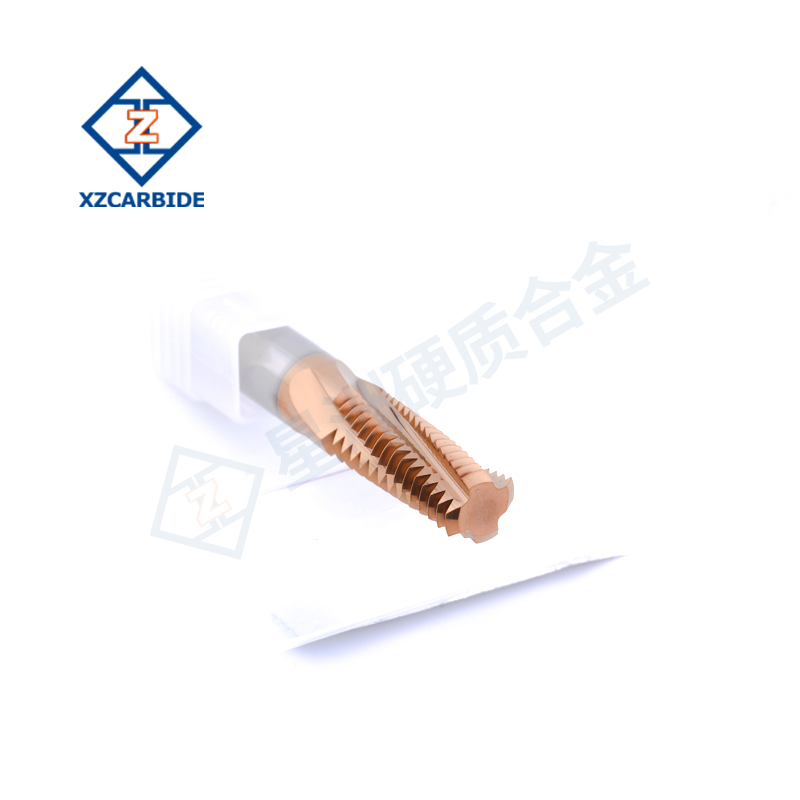

Product Features

Full-tooth cutting, high efficiency and precision

- The cutting edge covers the entire circumference, and the full-tooth cutting greatly improves the processing efficiency.

- Precise control of the cutting path ensures accurate thread size and smooth surface.

High quality material, durable and reliable

- High-quality cemented carbide is used as the base material, which has excellent wear resistance and impact resistance.

- High-performance coatings (e.g. TiALN) are applied to the tool surface to enhance cutting performance and extend service life.

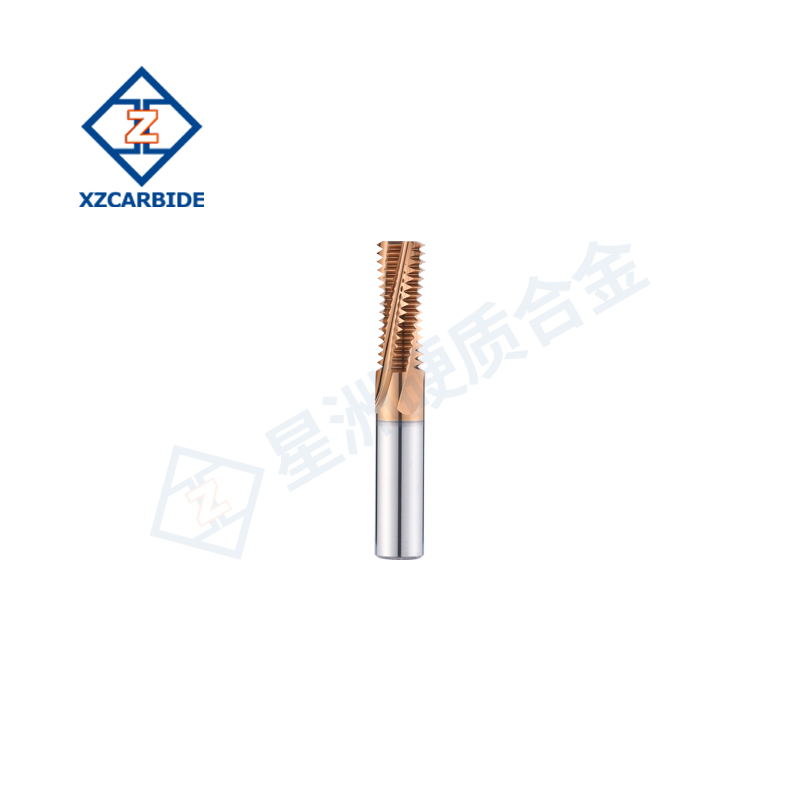

Stable machining, reduced vibration

- The full-tooth design helps maintain tool stability during machining, reducing vibration and deviation.

- Suitable for machining various materials, including but not limited to stainless steel, alloy steel, aluminum alloy, and more.

Flexible application, widely compatible

- Suitable for a variety of CNC machines and machining centers to meet different machining needs.

- Available to process different specifications of threads, including internal and external threads, to meet diversified processing requirements.

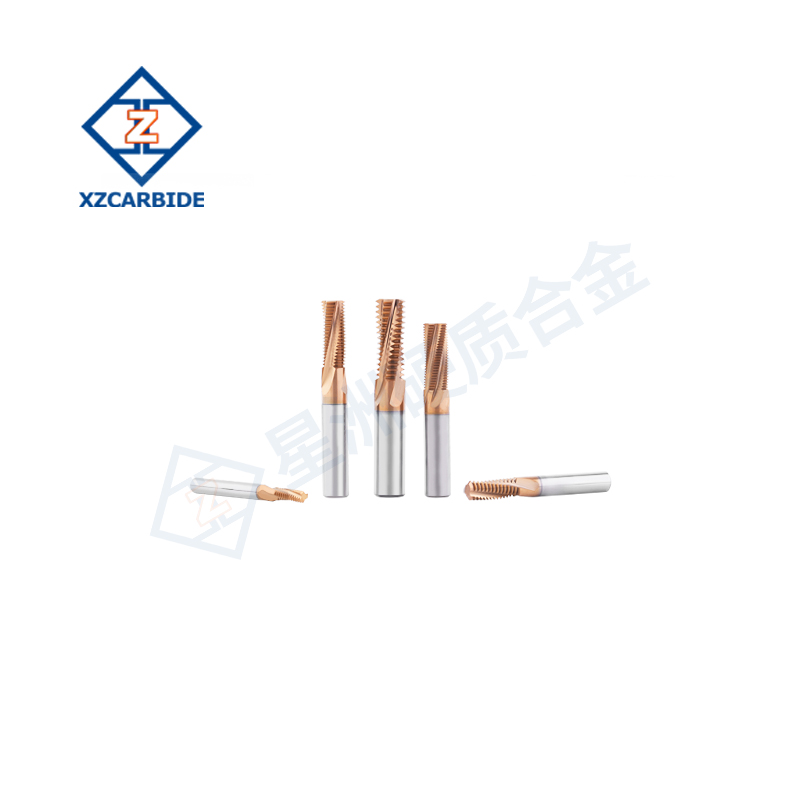

Product Parameters

Standard Type

| Blade Diameter | Blade Length | Shank |

| 6.0 | 6 | 15 |

| 8.0 | 8 | 20 |

| 10.0 | 10 | 25 |

| 12.0 | 12 | 30 |

| 14.0 | 14 | 45 |

| 16.0 | 16 | 45 |

| 18.0 | 18 | 45 |

| 20.0 | 20 | 45 |

Support Customize

Common Used Grades

| Grade | Hardness (HRC) | Grain Size (μm) | Bending Strength (N/mm2) |

| YG10X | 45 | 0.7 | 3320 |

| YL10.2&WF25 | 55 | 0.6 | 4000 |

Coating

| Type | Hardness (HV) | Thickness (μm) | Oxidation Temp. (℃) | Friction Coefficient | Color | Merits |

| AlTin | 3300 | 2.5-3 | 900 | 0.35 | Black | High heat stability. Suitable for high speed, dry cutting. Most suitable for carbide cutting tools, turning insert. |

| TiAlN | 2800 | 2.5-3 | 800 | 0.3 | Dark purple | Good thermal hardness. Excellent oxidation resistance. Good adhesion and resistance to bonding. |

| TiSiN | 4300 | 3 | 1000 | 0.25 | Copper | Suitable for heavy cutting, and high hardness cutting. Suitable for cutting mould steel, stainless steel. |

| Naco | 42(GPA) | 3 | 1200 | 0.4 | Blue | For high precision cutting. Suitable for high hardness cutting, mould steel processing. |

Reviews

There are no reviews yet.