Working Principle

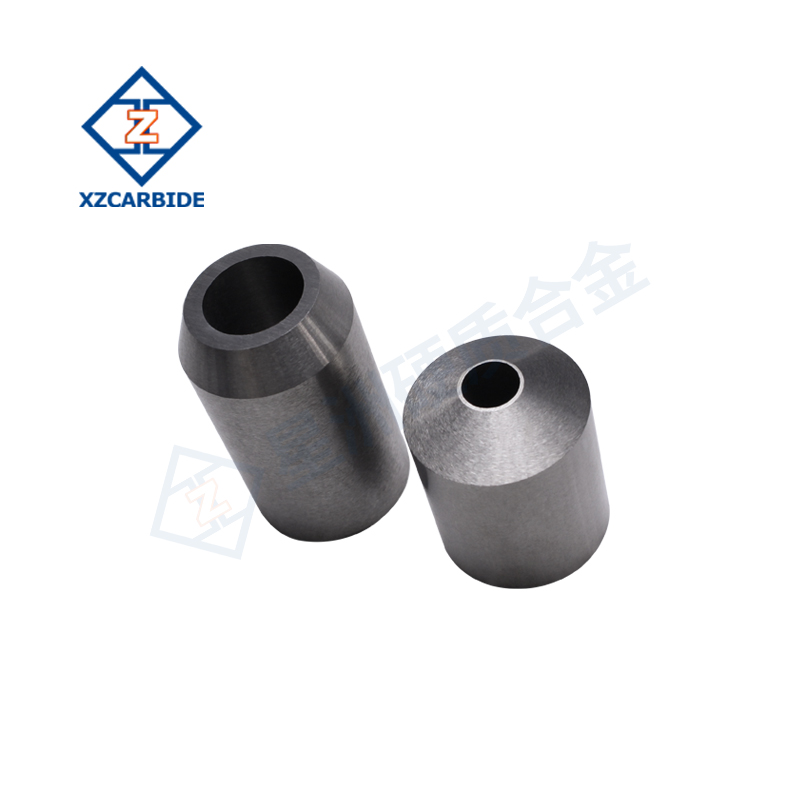

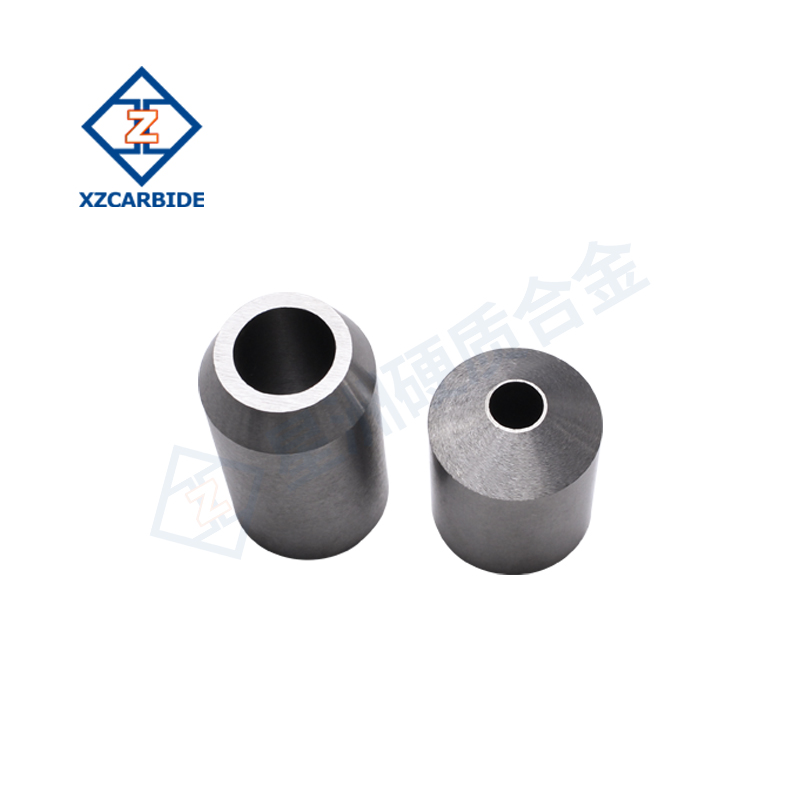

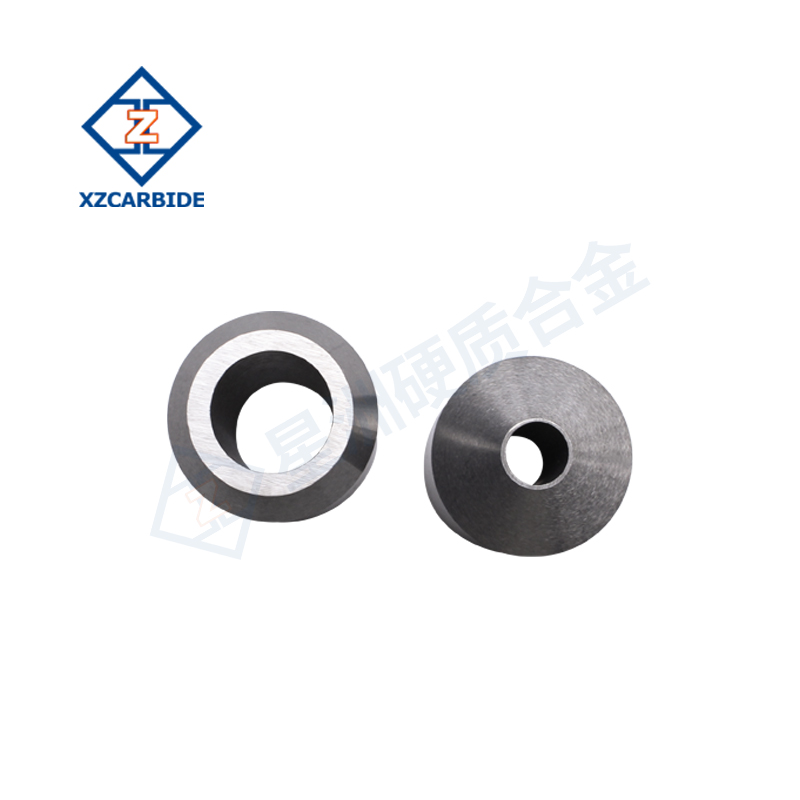

When working on a cold heading machine, the die, in conjunction with other tools, partially upsets and shapes the incoming metal bar to obtain the desired shape of the part. This process is usually carried out at room temperature without heating and that is why it is called cold heading. The cold heading process produces almost no scrap, resulting in significant savings in material costs.

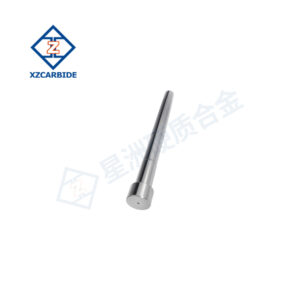

Main Features

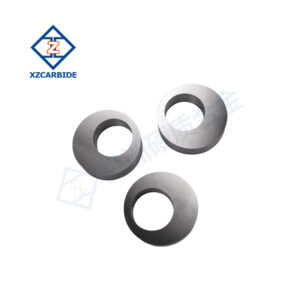

- High quality material: Made of high strength cemented carbide material with excellent wear resistance and durability.

- Precision machining: Through advanced CNC machining process and precision grinding, the high precision and stability of cold heading die are guaranteed.

- Efficient production: Cold heading technology can efficiently produce metal parts with complex shapes, improving production efficiency and cost-effectiveness.

- High material utilization: Material utilization rate can reach 80-90%, which significantly reduces material waste.

- High processing precision: Through accurate mold design and manufacturing, it is possible to obtain cold formed parts with complex shapes and precise dimensions.

- Multiple applications: Suitable for cold heading processing of different materials, including steel, aluminum, copper and other metal materials.

Reviews

There are no reviews yet.