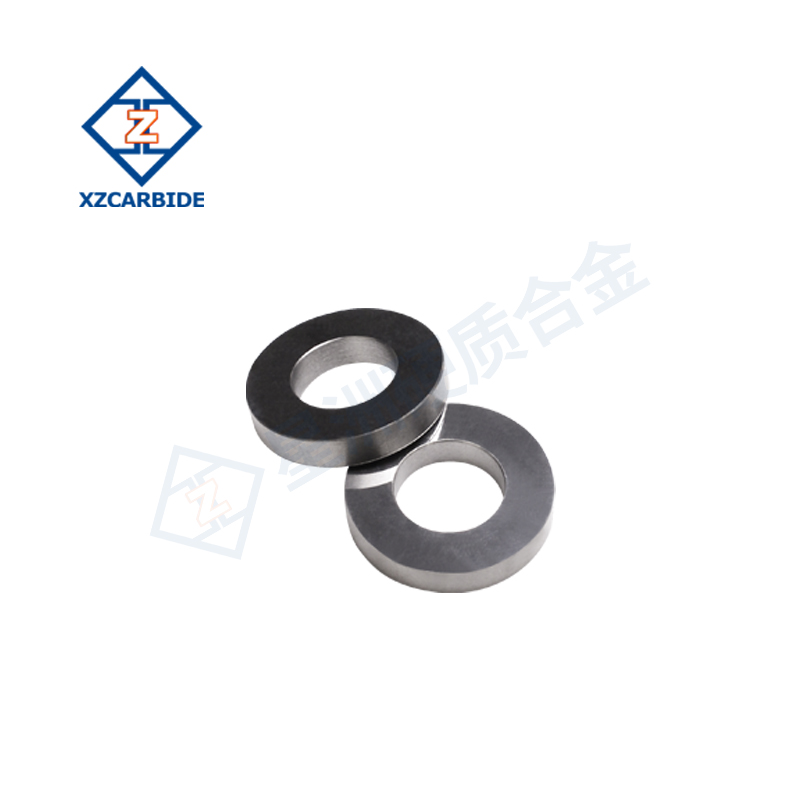

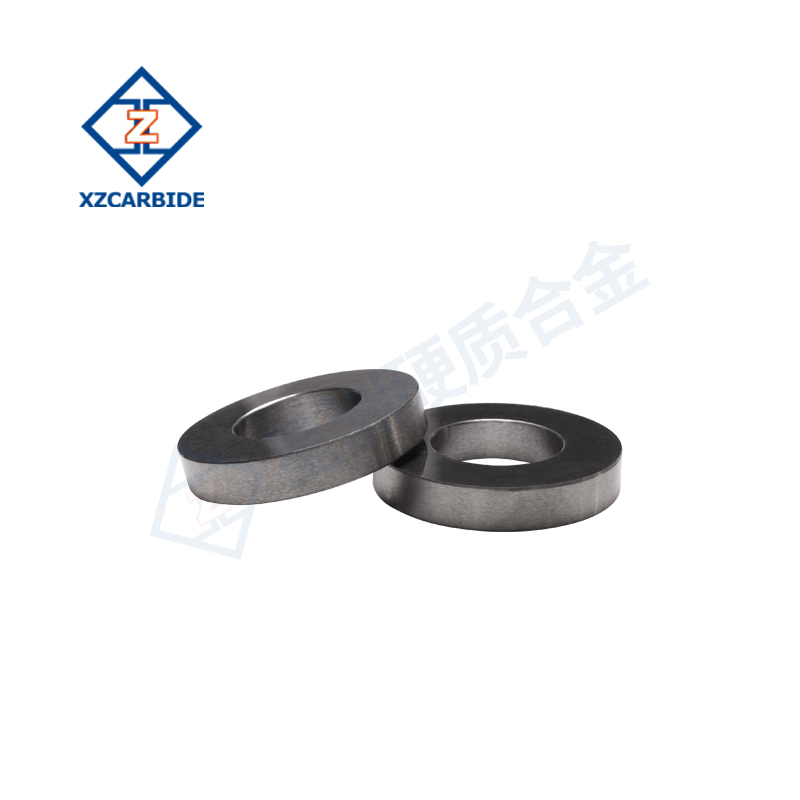

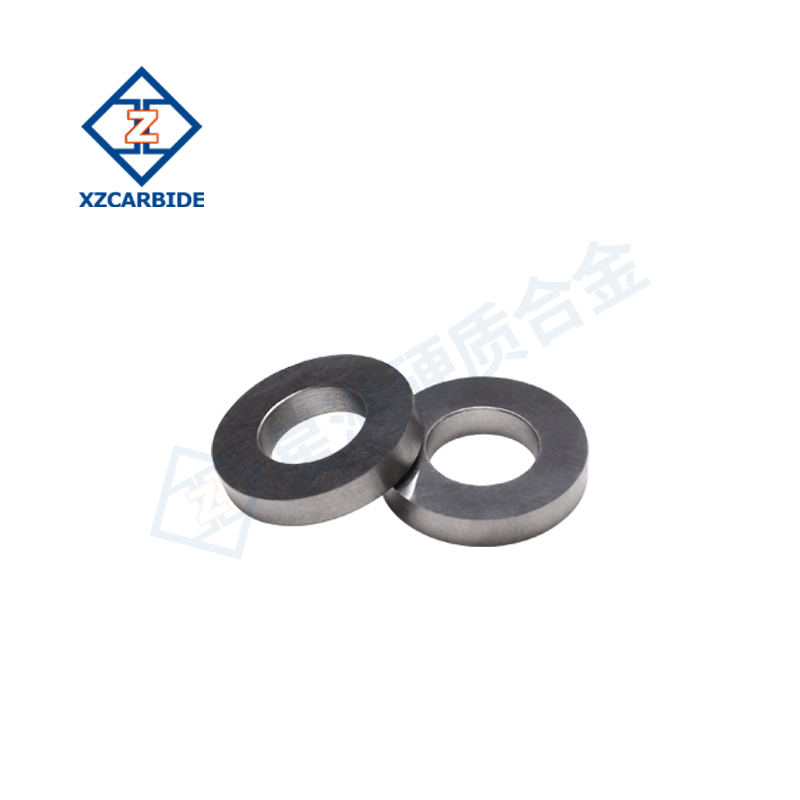

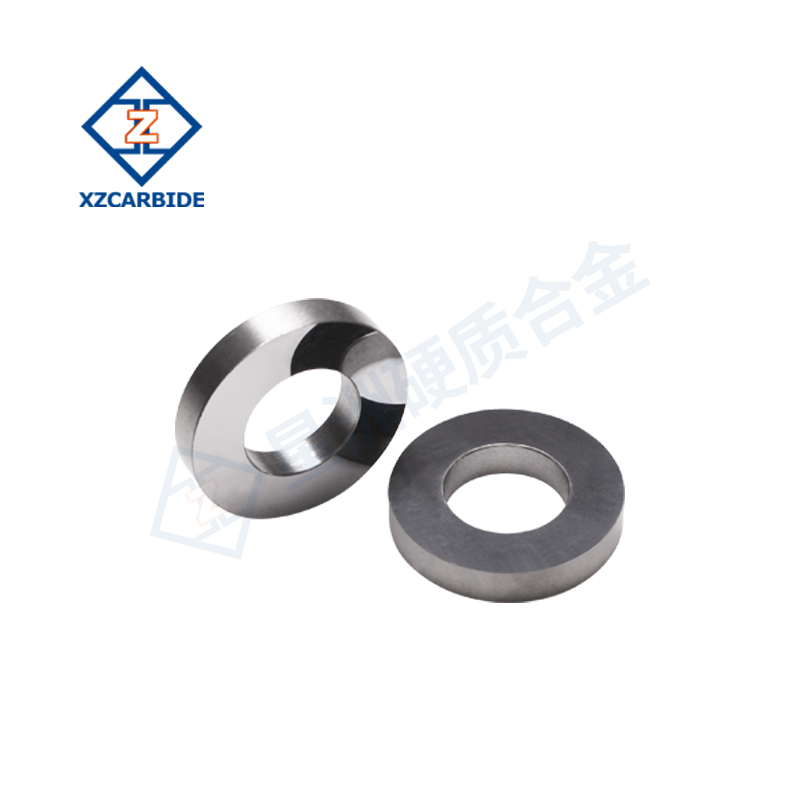

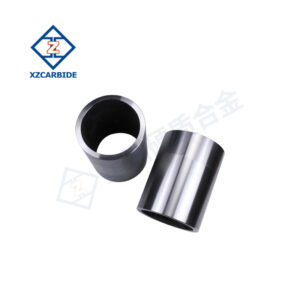

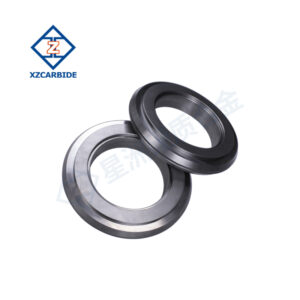

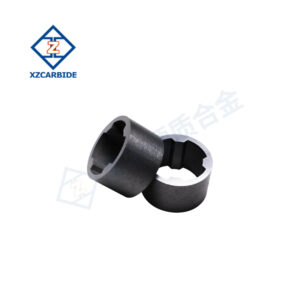

Product Features

- High hardness and wear resistance: Carbide wear rings are made of tungsten carbide and other hard compounds and bonded metals through powder metallurgy process, which have extremely high hardness and wear resistance, and can maintain stable shape and performance for a long time. They perform well under high load and high friction working environment, reducing equipment failure and downtime due to wear.

- Corrosion resistance: Good corrosion resistance to many chemical media, able to be used in harsh working environments for a long time without damage.

- High temperature resistance: Can maintain good hardness and strength under high temperature environment, suitable for high temperature working conditions.

- Customized service: Customize the wear rings of different sizes according to the specific needs of customers. Provide special treatment such as surface hardening and coating to enhance the performance of wear rings.

Applications

Carbide wear rings are particularly suitable for industrial equipment and components that require high wear resistance and long-term stability, such as:

- Mechanical processing: Used in pumps, compressors, centrifuges, mixers and other equipment to reduce equipment wear and improve operational efficiency.

- Metallurgy: Used as wear-resistant parts in the smelting process of iron and steel, non-ferrous metals, etc. to extend the service life of the equipment.

- Petrochemical: Used as corrosion-resistant, wear-resistant piping, valves and other parts in oil refining, chemical industry, etc. to ensure production safety.

- Construction: Used in the transmission system of heavy machinery, excavators and other equipment to enhance the performance of the equipment.

Common Used Grades

| Grade | Composition | Density (g/cm3) | Hardness (HRA) | Flexural Strength (MPa) | Properties |

| YG6 | 94% WC, 6% Co | 14.6 | 89 | 1520 | High hardness and good wear resistance , suitable for general wear and impact applications. |

| YG8 | 92% WC, 8% Co | 14.5 | 88.5 | 1600 | High hardness with impact resistance , suitable for medium impact and wear conditions. |

| YG15 | 85% WC, 15% Co | 14.0 | 86 | 2400 | High flexural strength and impact toughness , ideal for high impact and wear environments. |

| YG20 | 80% WC, 20% Co | 14.0 | 84 | 2800 | Extremely high flexural strength and toughness , ideal for high impact and high wear environments. |

Other grades are available on request

Reviews

There are no reviews yet.