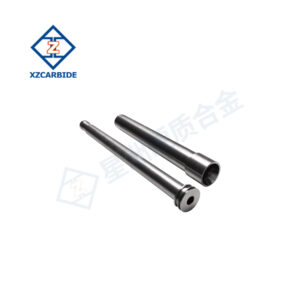

Product Introduction

Valve disc is one of the core components of a valve, and its main function is to block or allow fluid to pass through the valve by moving. The design and material of the valve disc is crucial to the sealing and operational performance of the valve, and is widely used in various types of industrial valves, such as gate valves, globe valves, butterfly valves and check valves.

Product Features

- Ultra-high hardness: Cemented carbide material makes the valve disc have extremely high hardness, suitable for high abrasion environment.

- Excellent wear resistance: Significant wear resistance extends the service life of the valve.

- Corrosion resistance: Resistant to a variety of acid and alkali corrosion, suitable for corrosive media.

- High temperature stability: Maintain stable performance and structural integrity in high temperature environments.

- Precision machining: Advanced machining technology is used to ensure the perfect fit of the valve disc and valve seat to achieve excellent sealing effect.

Product Parameters

| Materials | Tungsten carbide, stainless steel |

| Hardness | HRA 89-93 |

| Dimensions | Diameter: 20-1000 mm Thichness: 5-100 mm (Customization accepted) |

| Working Temperature | -40℃-600℃ |

| Working Pressure | 2500 PSI max. |

| Corrosion Resistance | Suitable for multiple corrosive media, including acids, alkalis and salt solutions. |

Common Used Grades and Their Performance

| Grade | Density (g/cm3) | Hardness (HRA) | Performance |

| YG6 | 14.8 | 89 | High hardness and good abrasion resistance, suitable for moderately corrosive environments. |

| YG8 | 14.7 | 91 | Excellent integrated performance for most corrosive and highly abrasive environments. |

| YG15 | 14.2 | 92 | Higher wear and impact resistance for extreme working conditions. |

Reviews

There are no reviews yet.