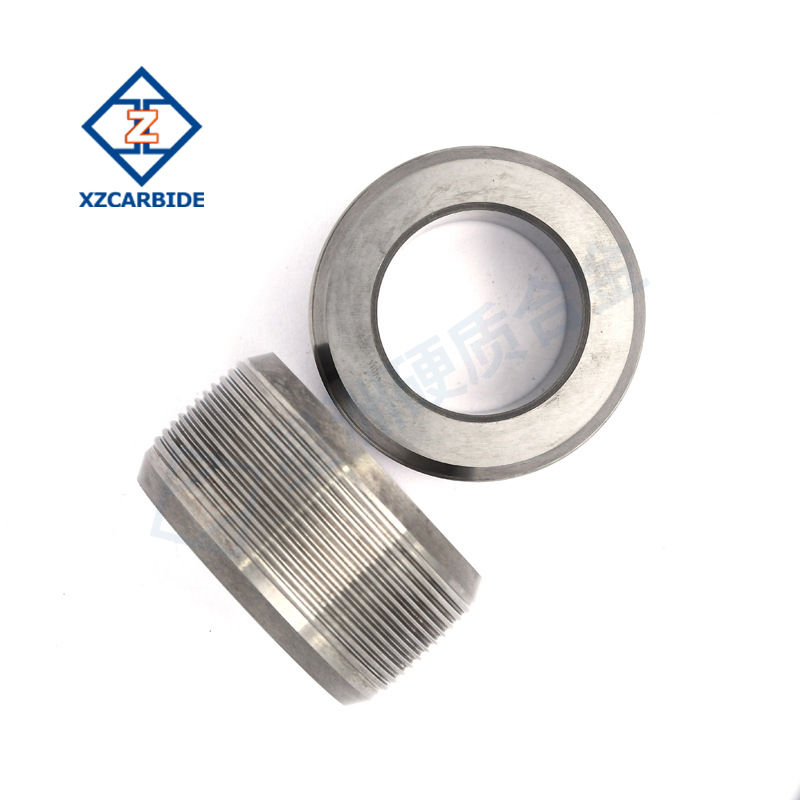

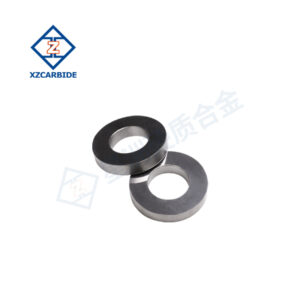

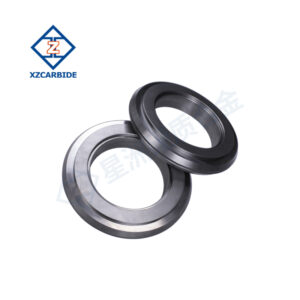

Product Performance

- Impact resistance and wear-resistant.

- High precision, can be customized according to drawings.

- Recommend applicable grades based on actual trial environment.

Tips: For non-standard and special-shaped cemented carbide products, please provide drawings.

Common Used Grades

| Grades | International Standards | Density (g/cm3) | Hardness (HRA) | Bending Strength (MPa) | Scope of Application |

| YG8 | K30 | 14.8 | 89.5 | ≥3500 | It has high strength, impact resistance and shock resistance, better than YG6. It is suitable for making forming knives and wear-resistant parts. |

| YG11 | K40 | 14.4 | 88.5 | ≥3650 | Suitable for making stamping molds. |

| NT15 | K40 | 14.0 | 87.5 | ≥3800 | Suitable for making stamping dies (processing silicon steel sheets), wear-resistant parts, etc. |

| YG20 | K30 | 13.5 | 85.5 | ≥4200 | It has high strength. Suitable for making progressive dies and other stamping dies |

| YG6X | K10 | 14.9 | 91.5 | ≥3200 | It is a fine-grained alloy with good wear resistance and is suitable for making forming knives and wear-resistant parts. |

| YL10.2 | K10 | 14.5 | 92 | ≥3850 | It is an ultra-fine grain alloy with high wear resistance, bending strength, anti-adhesion ability and pad strength. It is suitable for low-speed rough machining. |

Reviews

There are no reviews yet.