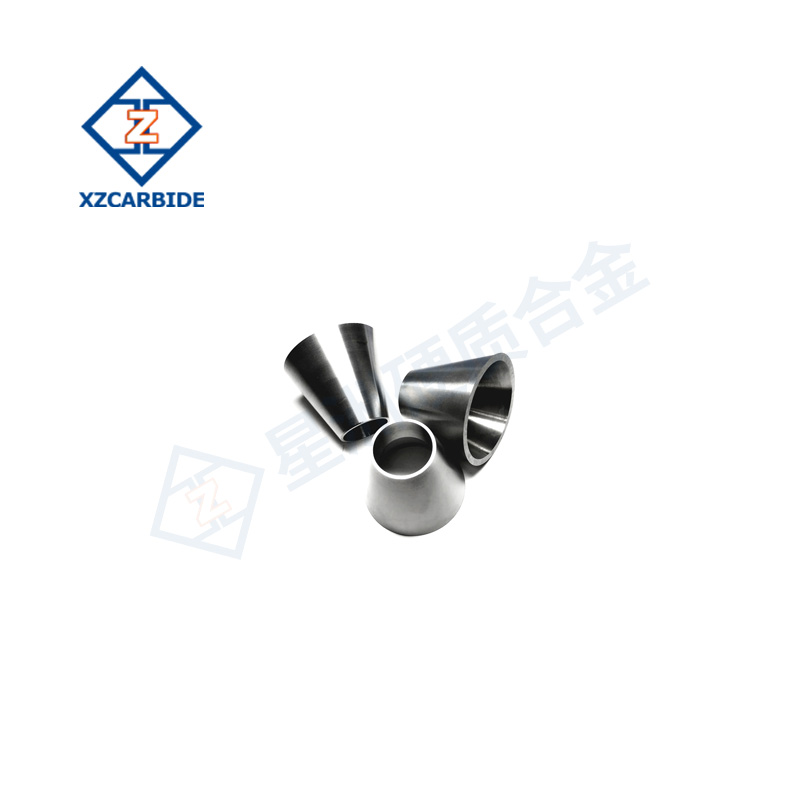

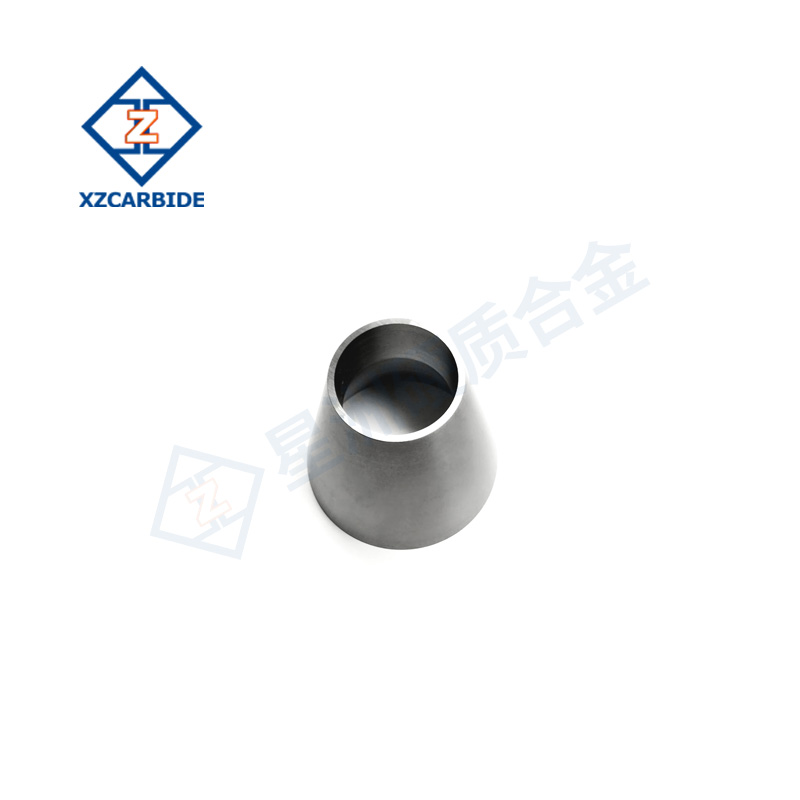

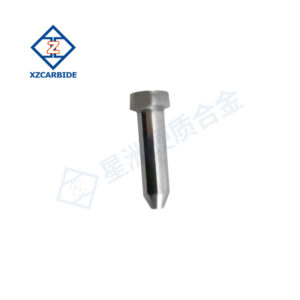

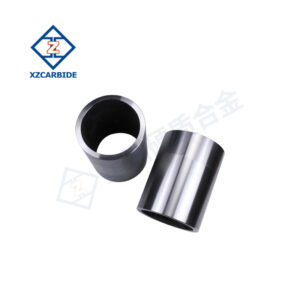

Main Features

- High hardness: Adopting tungsten carbide material, it has extremely high hardness and can withstand the impact of high-speed sand flow for a long time.

- Strong abrasion resistance: Excellent abrasion resistance enables it to maintain good performance under high-frequency use, prolonging its service life.

- High efficiency: The specially designed nozzle shape ensures efficient spraying of the sand stream and improves the working efficiency.

- Corrosion resistance: Tungsten carbide material has good corrosion resistance and is suitable for various complex environments.

- Multi-specification options: A wide range of specifications and sizes are available to meet the needs of different sand blasting equipment and processes.

Technical Parameter

| Material | Cemented carbide, borated carbon, tungsten carbide |

| Hardness | Above HRA 90 |

| Density | Varies by material |

| Melting Point | 2450 °C |

| Jet Flow Rate | Customizable |

| Spray Angle | Customizable |

| Abrasion and Impact Resistance | Strong |

| Expected Service Life | Up to 500 hours with different abrasives |

Use and Maintenance

- Before use, the sandblasting nozzle should be inspected for damage or clogging to ensure that the nozzle is in good condition.

- Install the sand blasting nozzle correctly according to the instruction manual, and make sure it is tightly connected with the sand blasting machine.

- In the course of use, the sand and impurities inside the sand blasting nozzle should be cleaned regularly to prevent clogging.

- Replace the sand blasting nozzles with serious wear and tear periodically according to the usage condition to ensure the efficiency and quality of the sand blasting operation.

Applications

- Aerospace: Surface cleaning and strengthening treatment of aircraft parts.

- Automobile manufacturing: Surface treatment and descaling of automobile body and parts.

- Ship repairing: Surface cleaning and pre-coating treatment of ship hulls.

- Petrochemical industry: Surface treatment and descaling of pipelines and storage tanks.

- Machinery manufacturing: Surface cleaning and strengthening of various mechanical parts.

- Metal surface treatment: For cleaning, deburring and removing oxidized skin on metal surfaces.

- Mold cleaning: Efficiently clean the molds and restore the precision of the molds.

Reviews

There are no reviews yet.