Main Features

- Chipless drilling: Through the hot-melt drilling process, the material is heated, melted and shaped without removing excess material, reducing waste.

- Efficient processing: High-speed rotation and high-temperature thermal fusion make the drilling process more efficient and save processing time.

- High-strength connection: The threaded holes formed have high-strength connectivity and are suitable for applications requiring high-strength fastening.

- Multifunctionality: Drilling and threading can be accomplished at the same time, reducing processing steps and improving productivity.

- Widely applicable materials: Suitable for many metal materials such as steel, stainless steel, aluminum, copper, etc., especially suitable for the processing of thin-walled materials.

Working Principle

- High-temperature softening: In the process of high-speed rotation, the hot melt drill rubs against the surface of the metal material and generates high temperature (usually more than 600°C), which softens the surface of the metal.

- Pressure extrusion: The rapid feed and pressure of the hot melt auger extrudes and stretches the softened metal portion to form a bushing that is thicker than the original metal thickness.

- Thread Forming: Threads are extruded and formed directly into the metal bushing; these threads have high tensile and torsional strength.

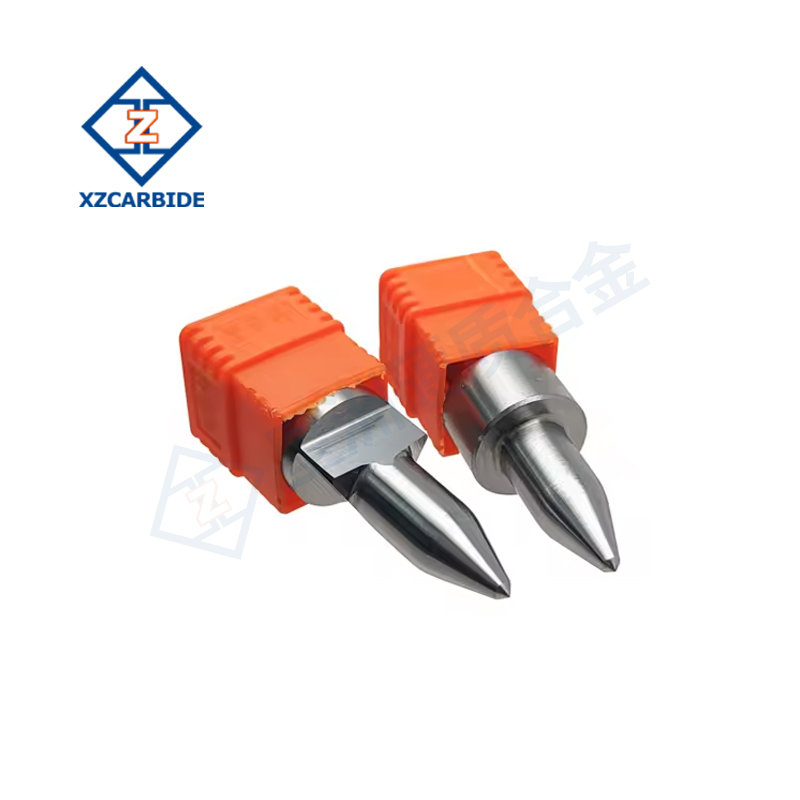

Classification

Depending on the surface requirements of the workpiece, hot melt drills can be categorized into round hot melt drill and flat hot melt drill.

- Round hot melt drill: While penetrating the workpiece and stretching to form the bushing, a convex ring is formed on the surface of the workpiece. This convex ring can be used for a variety of purposes to strengthen the connection effect, such as extruding and tapping, screwing and forming, or as a bearing support seat, bifurcated throat connection, etc.

- Flat hot melt drill: While penetrating the workpiece and stretching it to form a bushing, it cuts away the collar from the surface of the workpiece, resulting in a smooth surface. It is especially suitable for machining scenarios where smooth joint surfaces or chamfered holes are required.

Depending on the thickness of the workpiece, there are two types of hot melt drills: short hot melt drill and long hot melt drill.

- Short hot melt drill: Suitable for penetrating workpiece thickness between 0.8mm~3mm.

- Long hot melt drill: Suitable for penetrating workpiece thickness greater than 3mm~12mm.

Specification

Example of 2mm mild steel

Thread Size | Pitch/Inch | Diameter (mm) | Drilling Machine Speed (RPM) | Drilling Machine Power (kw) | Feed Speed (mm/min) | Drilling Time (s) | Tapping Machine Speed (RPM) |

M2 | 0.4 | 1.8 | 3200 | 0.5 | 80 | 2 | 1600 |

| M3 | 0.5 | 2.7 | 3000 | 0.6 | 100 | 2 | 1350 |

M4 | 0.7 | 3.7 | 2600 | 0.7 | 120 | 2 | 1000 |

| M5 | 0.8 | 4.5 | 2500 | 0.8 | 150 | 2 | 800 |

M6 | 1.0 | 5.3 | 2400 | 1.0 | 150 | 2 | 650 |

| M8 | 1.25 | 7.3 | 2200 | 1.3 | 150 | 2 | 500 |

M10 | 1.5 | 9.2 | 2000 | 1.5 | 150 | 3 | 400 |

| M12 | 1.75 | 10.9 | 1800 | 1.7 | 150 | 3 | 330 |

M14 | 2.0 | 13.0 | 1600 | 2.0 | 150 | 4 | 300 |

| M16 | 2.0 | 14.8 | 1400 | 2.2 | 150 | 4 | 250 |

M18 | 2.5 | 16.7 | 1400 | 2.5 | 150 | 5 | 220 |

| M20 | 2.5 | 18.7 | 1200 | 2.7 | 150 | 5 | 200 |

Applications

The hot melt drill is suitable for processing a wide range of metal materials, including iron, alloy, stainless steel, brass, purple copper, aluminum alloy and so on. It has a wide range of applications, including but not limited to:

- Spare parts for automobiles, motorcycles, battery cars

- Sheet metal, air conditioning, radiator

- Furniture, medical equipment, fitness equipment

- Shelves, containers

Reviews

There are no reviews yet.