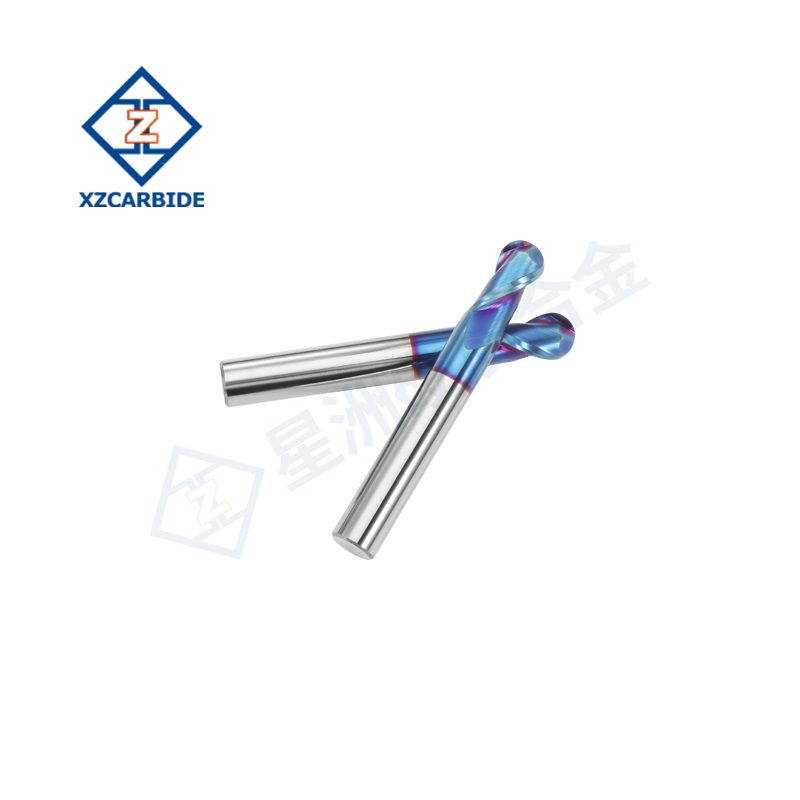

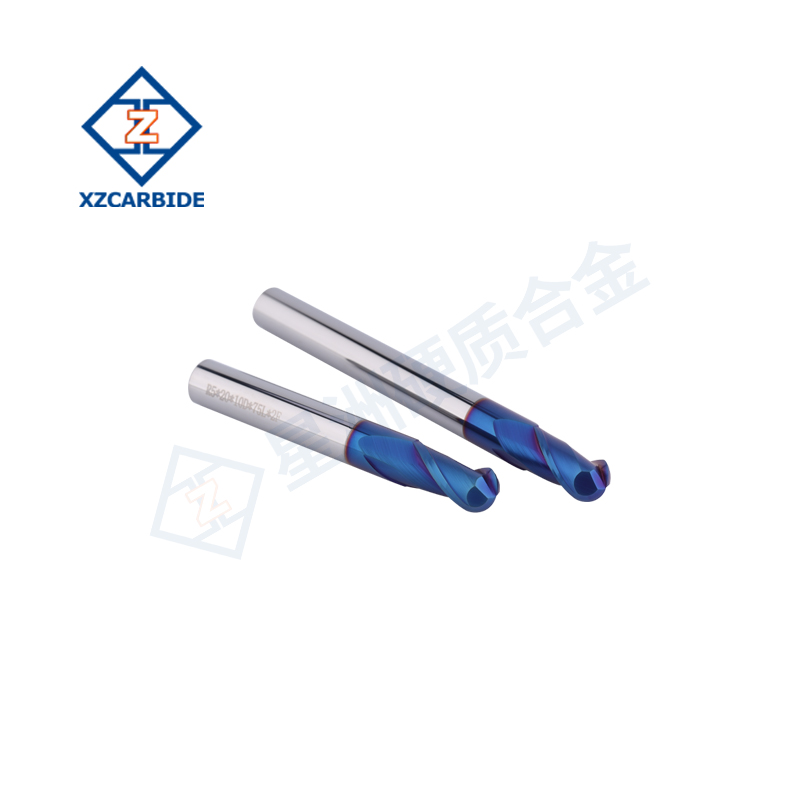

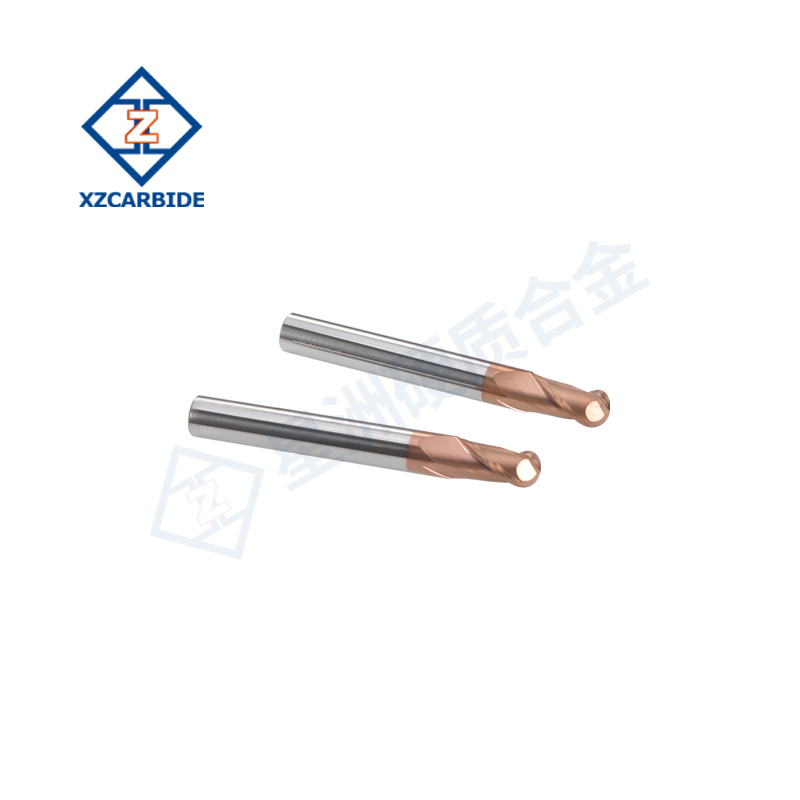

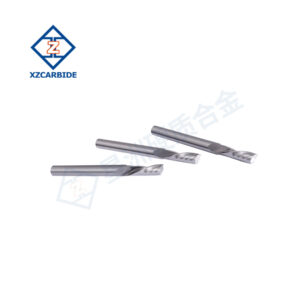

Widely used in mold manufacturing, mechanical processing, aerospace, and automotive industries, the ball nose end mill is known for its excellent wear resistance, high precision, and versatility, making it an ideal choice for various precision machining and demanding applications.

Products Features

- Special cutting edge: increase the cutting ability and extend the lifetime of tools and machines.

- Smooth and wide flute: remove the cuttings more easily

- Heat-resistant coating: can be used for high-speed processing.

- High quality raw material: use high toughness, grain-sized carbon tungsten.

- Polished surface: reduce the friction coefficient, improve the lathe efficiency, save more production time.

Product Parameters

Basic information

| Material | Carbide, tungsten steel, tungsten carbide |

| Flute | 2/3/4/6 Flute |

| Shank diameter | 4-40 mm |

| Flute diameter | 0.3-40 mm |

| Overall length | 38-330 mm |

| Coating | AlTiN, TiAIN, TiSiN, nACo |

| Size | Standard size or as your request |

Coating

| AITiN | TiAIN | TiSiN | nACo | |

| Hardness(HV) | 3200 | 2800 | 3600 | 42(GPA) |

| Thickness(μm) | 2.5-3 | 2.5-3 | 3 | 3 |

| Oxidation Temp | 900 | 800 | 1000 | 1200 |

| Friction Coeffient | 0.3 | 0.3 | 0.45 | 0.4 |

| Color | Black | Violet | Copper | Blue |

Reviews

There are no reviews yet.