Introduction

In modern industrial production, carbide nozzles, as key fluid control components, are widely used in various operating environments such as spraying, cleaning, cooling and cutting. Their excellent wear and corrosion resistance make them ideal for many harsh conditions. The purpose of this text is to comprehensively analyze the performance characteristics, application areas, and manufacturing technologies of carbide nozzles, providing readers with an opportunity to gain a deeper understanding of the field.

Performance Characteristics of Carbide Nozzles

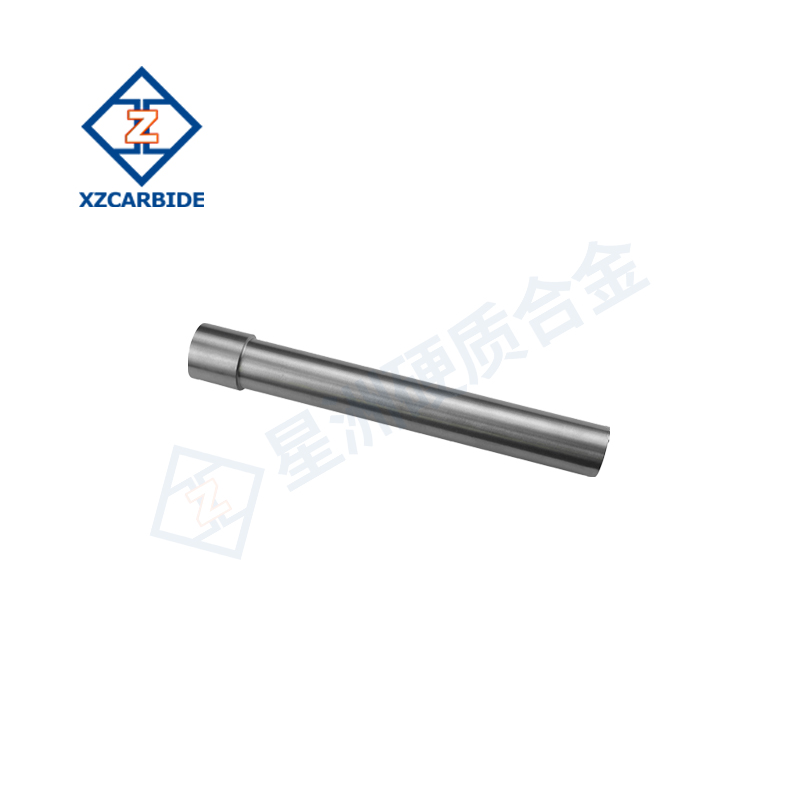

Carbide nozzles, typically made from a composite of tungsten carbide (WC) and cobalt (Co), are a combination of materials that gives the nozzle a unique set of properties:

High hardness and wear resistance: The hardness of carbide is second only to diamond, allowing it to maintain its structural integrity even in the face of high-speed fluid impact, significantly extending the life of the nozzle.

Corrosion resistance: Carbide has excellent chemical stability, it can resist the erosion of a variety of corrosive media, suitable for conveying acid and alkali solutions or other corrosive fluids.

Thermal stability: In a high temperature environment, carbide nozzles are able to maintain the stability of their physical and chemical properties, suitable for high temperature fluid transmission and control.

Precise fluid control: The internal structure of carbide nozzles can be precisely designed to realize precise control of fluid flow, pressure and spraying angle to meet the needs of different industrial applications.

Application Areas of Carbide Nozzles

Carbide nozzles are widely used in several fields due to their unique advantages:

Spraying operation: In the spraying process of paints, coatings, anticorrosives, and other materials, carbide nozzles can ensure uniform atomization effect to improve the quality and efficiency of coating.

Waterjet cutting: A fine beam of high-pressure water is formed through the carbide nozzle, which is used to cut metal, stone, ceramics and other materials with high cutting precision and good edge quality.

Cleaning and cooling: In the process of cleaning and cooling of mechanical equipment, carbide nozzles can provide stable fluid jet, effectively remove dirt and control temperature.

Agricultural irrigation: Carbide nozzles are used in agricultural irrigation systems to accurately control water distribution and improve the utilization of water resources.

Chemical: Carbide nozzles are used in the production of chemicals for precise metering and mixing of fluids, ensuring the stability and safety of the reaction process.

Manufacturing Technology for Carbide Nozzles

The manufacturing of carbide nozzles involves several complex technical aspects:

Powder metallurgy: First, tungsten carbide powder is mixed with cobalt powder in a certain proportion, and blanks are made by pressing or injection molding.

Sintering process: The blanks are sintered at high temperature to melt and fill the cobalt powder between the tungsten carbide particles to form a dense cemented carbide structure.

Precision machining: High-precision CNC machine tools are used for precision cutting of the sintered material to ensure the dimensional accuracy and surface finish of the nozzles.

Surface treatment: In order to further enhance the performance of the nozzle, surface treatment techniques such as plating and heat treatment can be used to enhance its wear resistance and corrosion resistance.

Conclusion

Carbide nozzles play an indispensable role in industrial production due to their excellent performance. With the continuous progress of material science and manufacturing technology, the performance of carbide nozzles will be further improved and the range of applications will be expanded, bringing higher efficiency and lower operating costs to various industries. For manufacturers and users, understanding the characteristics of the nozzles and selecting the right product is critical to improving productivity and product quality.

By choosing to work with Xingzhou, you will enjoy the following significant advantages:

- Industry-leading technology and quality: With years of accumulated expertise and cutting-edge manufacturing technology, we produce nozzles with exceptional durability and precision, ensuring your production process is efficient and stable.

- Customized solutions: Our team of experts can provide products and services tailored to your specific needs, ensuring that each nozzle is perfectly matched to your application.

- Rapid response and technical support: We promise to provide timely customer support, from consultation to after-sales service, accompanied by the whole process, to solve any problems you encounter in the process of use.

- Continuous Innovation and Improvement: We continuously invest in research and development to pursue product innovation and upgrading to ensure that you are always at the forefront of the industry and enjoy the benefits of the latest scientific and technological achievements.

- Reliable partnership: We value the long-term cooperation with every customer, and establish a partnership of mutual trust and mutual benefit through high-quality products and services to jointly promote business development.

Choosing us means choosing professionalism, efficiency and peace of mind!

FAQs

1. Are stainless steel nozzles better than carbide nozzles?

Carbide nozzles and stainless steel nozzles each have their advantages and disadvantages. Carbide offers high hardness, excellent wear resistance, good thermal stability, and corrosion resistance, but expensive and brittle. Stainless steel provides strong corrosion resistance, good toughness, moderate cost, and are easy to machine, but lower wear resistance and hardness. Carbide nozzles are suitable for high-wear environments, while stainless steel nozzles are better for corrosive environments and cost-sensitive applications.

2. Which nozzle tip material is most resistant to abrasion?

Nozzle tips made of tungsten carbide and ceramic are highly resistant to abrasion and corrosion and are the best material for high pressures and wettable powders.