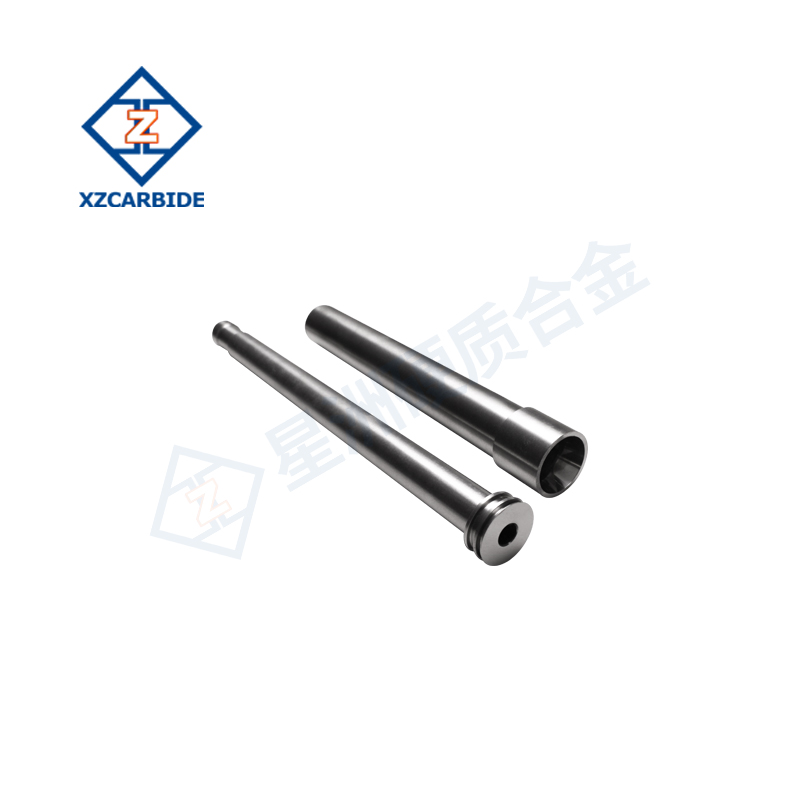

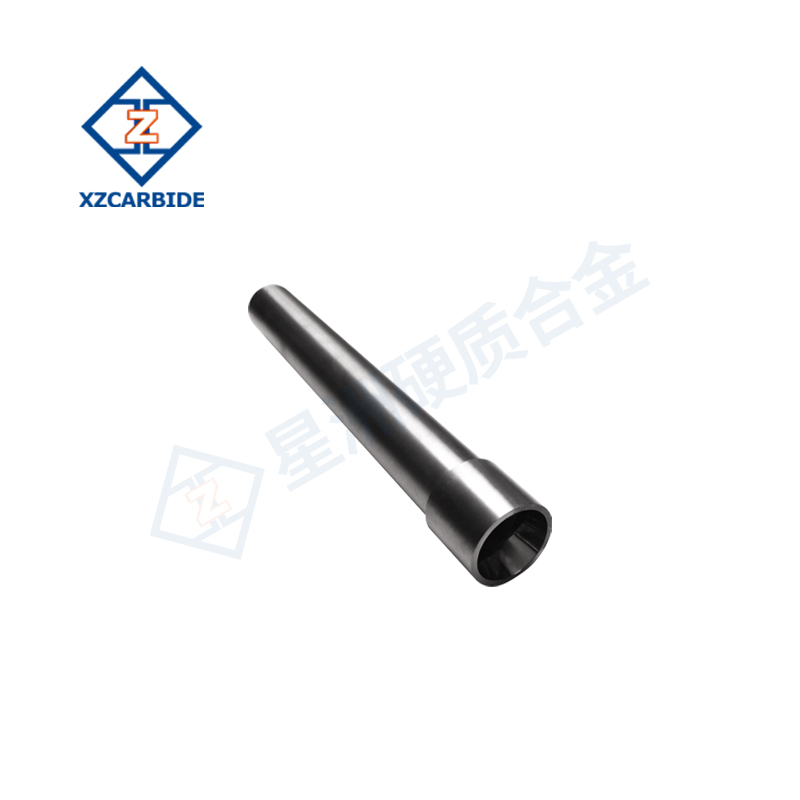

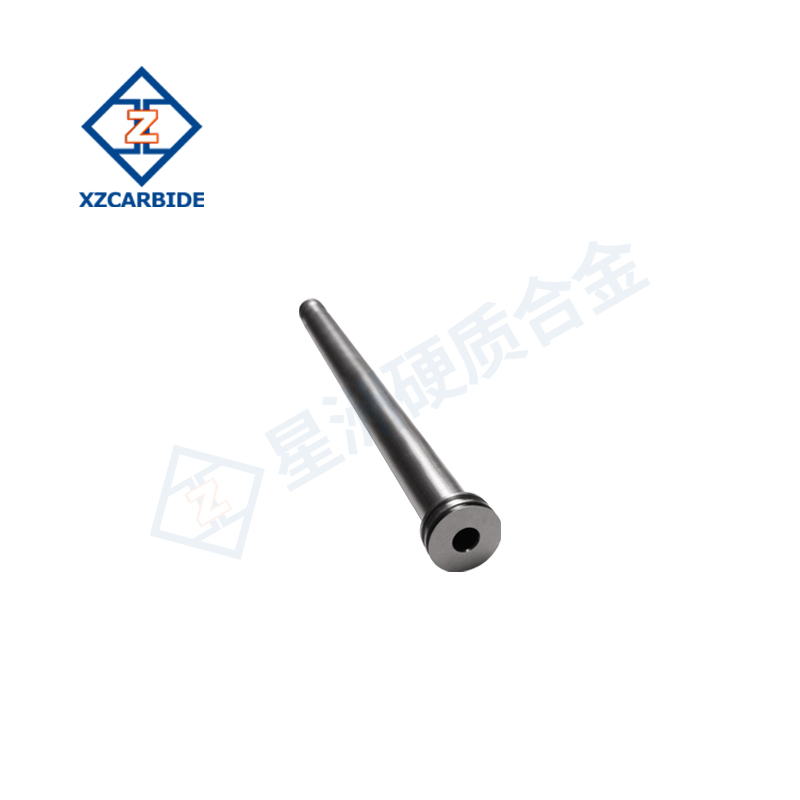

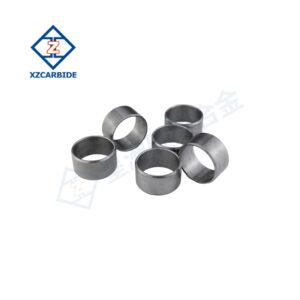

Product Features

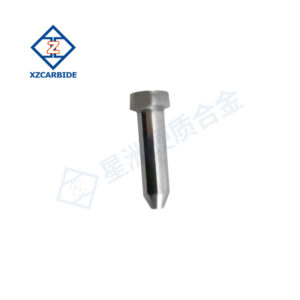

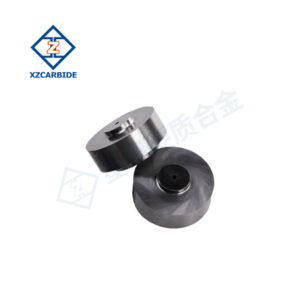

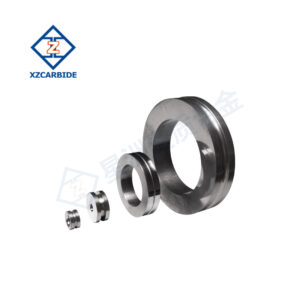

- High hardness and abrasion resistance: Extremely high hardness and abrasion resistance enable the nozzle to maintain a long service life under the impact of high-pressure water flow.

- Precise control: Control the jetting direction and speed of the water flow accurately to ensure the precision and stability of the cutting.

- Wide application: Suitable for cutting various materials, including metal, non-metal, composite materials, with wide applicability.

- Environmentally friendly: The water cutting process does not produce harmful gases and dust, which is friendly to the environment.

- Multiple sizes: Provide various inner diameters and lengths of nozzles to meet different cutting needs.

Product Parameters

| Materials | Pure tungsten carbide |

| Hardness | HRA 96.5 |

| Dimensions | Upon request |

| Working Temperature | -20℃-60℃ |

| Working Pressure | 420 MPa max. |

| Corrosion Resistance | Suitable for multiple corrosive media, including acids, alkalis and salt solutions. |

Application Areas

Carbide water cutting nozzles are widely used in the following fields:

- Metal processing: To cut various metal materials such as stainless steel, aluminum alloy, titanium alloy and so on.

- Construction: Used for cutting stone, concrete, tiles and other building materials, suitable for building decoration and building construction.

- Glass processing: For cutting different kinds of glass products, ensuring smooth cutting edges and no cracks.

- Composite materials: Cutting carbon fiber, glass fiber and other composite materials, used in aerospace and automotive industries.

- Shipbuilding: Used to cut ship hulls and components to meet the high precision requirements of the shipbuilding process.

Reviews

There are no reviews yet.