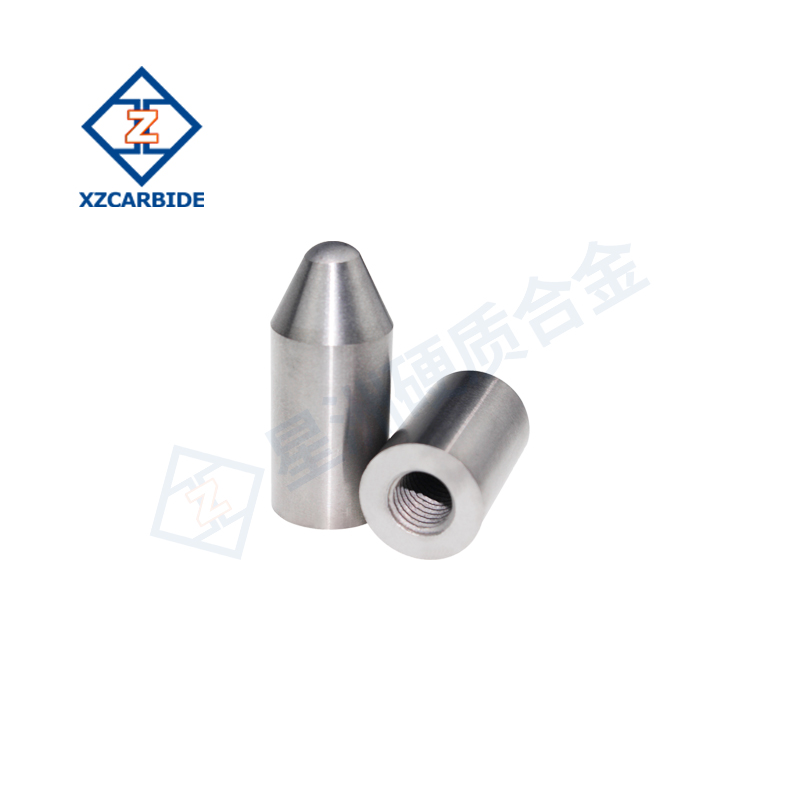

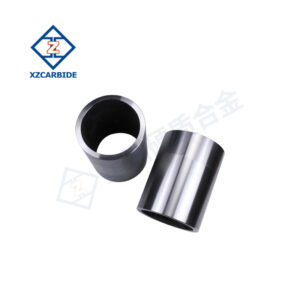

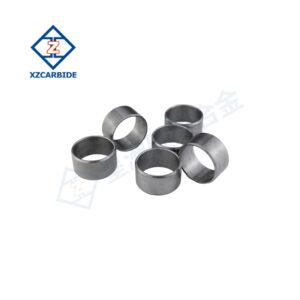

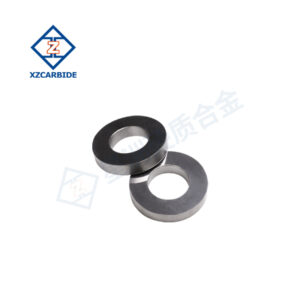

Product Description

- Cemented carbide wear parts belong to tungsten carbide, also called cemented carbide, hard metal.

- Excellent performance and wide range of use. Carbide special shaped wear parts have high quality, hardness and tolerance.

- Good wear resistance and high hardness make it suitable for making high abrasion and corrosion wear parts, mechanical parts, drawing dies and more.

- We can do various models as your request.

Advantages of Cemented Carbide Wear Parts

- 100% tungsten carbide raw material.

- Stable chemical properties, does not even oxidize at high temperature.

- Well equipment and workmanship.

- Stable and continuous production ability.

- Strictly inspected.

- High quality manufacturing management and professionals.

Different Grades

| Grade | WC % | Co % | Density g/cm³ | Hardness HRA |

| YG6 | 94 | 6 | 14.7-15.1 | 89.5 |

| YG8 | 92 | 8 | 14.6-14.9 | 89 |

| YG11 | 89 | 11 | 14.3-14.8 | 88 |

| YG15 | 85 | 15 | 13.9-14.2 | 86.5 |

| YG20 | 80 | 20 | 13.4-13.8 | 83.5 |

| YG20C | 80 | 20 | 13.4-13.8 | 82 |

| YL10.2 | 90 | 10 | 14.40-14.55 | 92.5 |

| YGH20 | 90 | 10 | 14.2-14.5 | 86.0 |

| YGH25 | 88 | 12 | 14.0-14.3 | 84 |

| YGH30 | 85 | 15 | 13.8-14.2 | 83.5 |

| YGH40 | 82 | 18 | 13.4-13.9 | 83 |

| YGH45 | 80 | 20 | 13.3-13.9 | 82 |

| YGH55 | 74 | 26 | 12.6-13.2 | 81 |

| YGR20 | 90 | 10 | 14.2-14.8 | 85 |

| YGR25 | 87.5 | 12.5 | 14.0-14.3 | 83 |

| YGR30 | 85 | 15 | 13.8-14.3 | 83 |

| YGR40 | 82 | 18 | 13.5-13.9 | 82 |

| YGR45 | 80 | 20 | 13.4-13.9 | 80.5 |

| YGR55 | 75 | 25 | 12.9-13.4 | 79 |

| YGR60 | 70 | 30 | 12.6-13.1 | 78.5 |

Our Advantages

- We have competitive price, on time delivery, high quality and good service. Our aim is to let you feel satisfied with our product. Our staff will try our best to meet your request.

- Small quantity orders are also accepted.

Reviews

There are no reviews yet.