Common Types

Carbide valve components come in various types, including but not limited to the following:

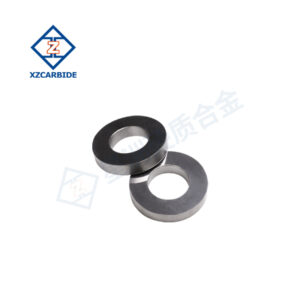

- Valve Seats: Work closely with the valve ball or valve plate to ensure sealing performance when the valve is closed.

- Valve Balls/Plates: Act as the opening and closing parts of the valve, enduring fluid pressure and erosion.

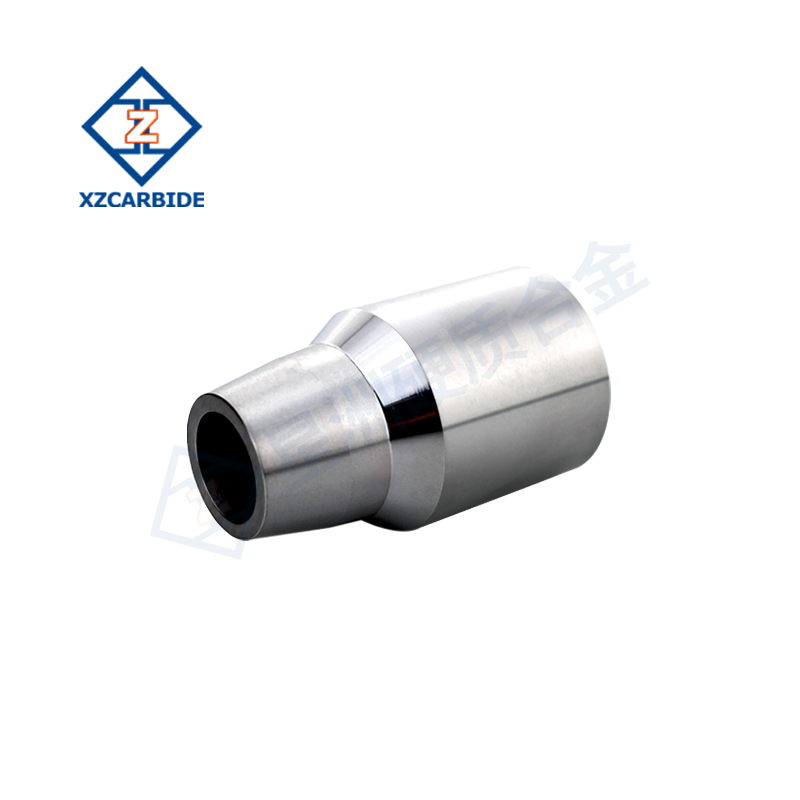

- Valve Stems: Connect the valve’s operating mechanism with the opening and closing parts, transmitting operational force.

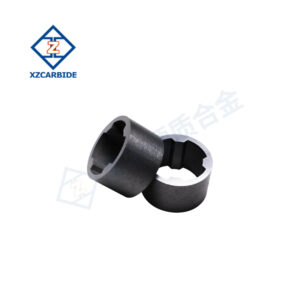

- Bushings: Protect the valve stem from wear while reducing friction resistance.

- Sealing Rings: Enhance the valve’s sealing effect to prevent fluid leakage.

Application Fields

Carbide valve components are widely used in the following fields:

- Oil Drilling: Used in valve systems for well control and oil and gas transportation.

- Deep-Sea Drilling: Perform excellently in high-pressure, highly corrosive deep-sea environments.

- Chemical and Pharmaceutical: Required for handling corrosive chemicals, needing corrosion-resistant, high-temperature valve parts.

- Power and Metallurgy: Able to withstand high temperatures, high pressures, and intense erosion during power generation and metallurgical processes.

Reviews

There are no reviews yet.