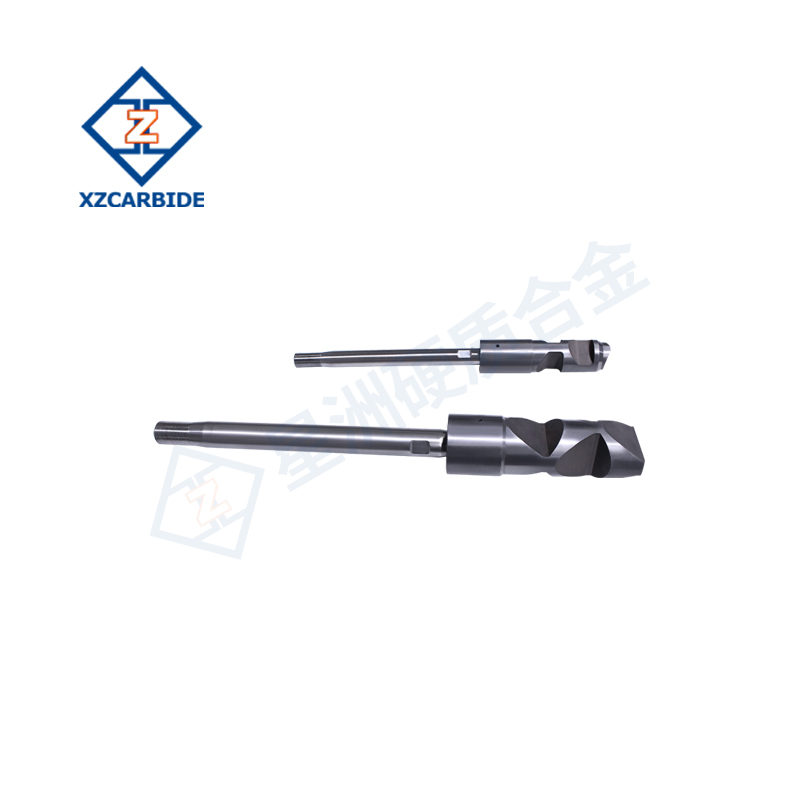

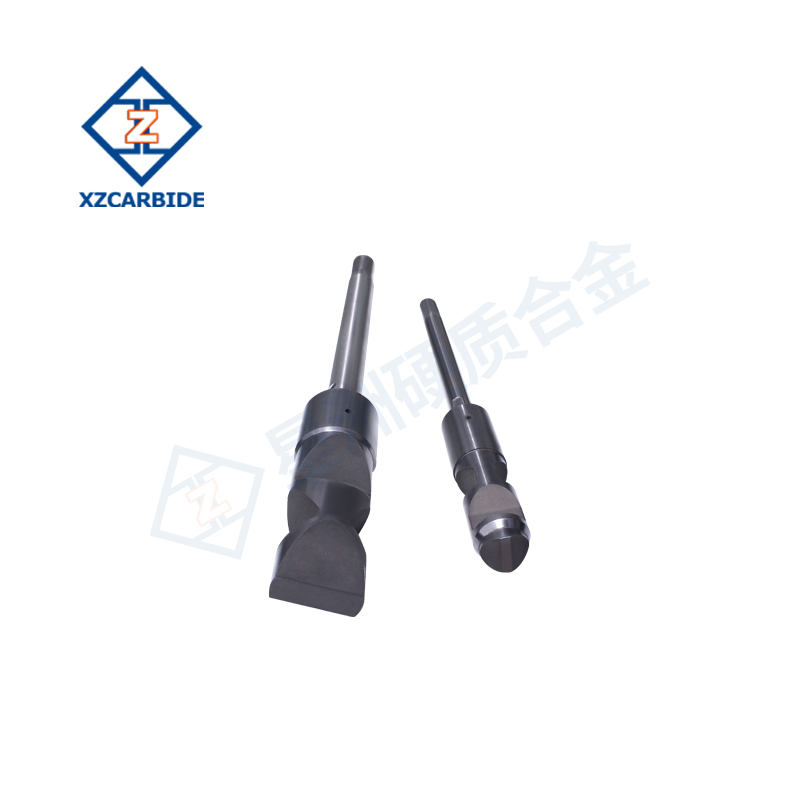

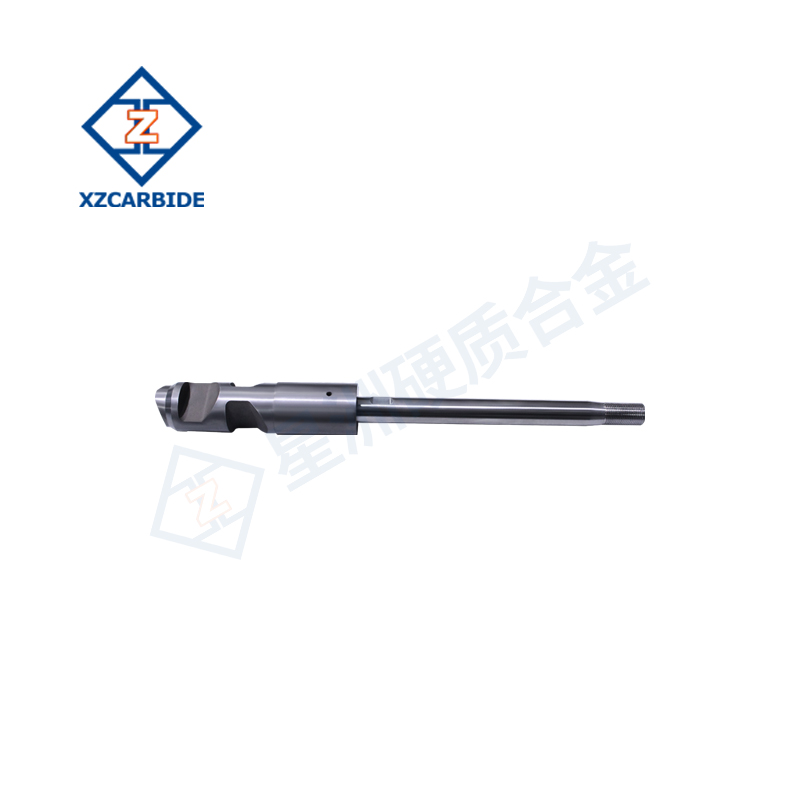

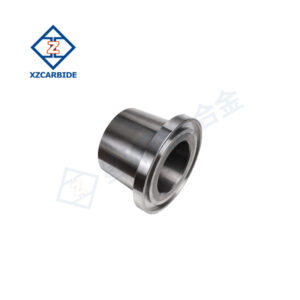

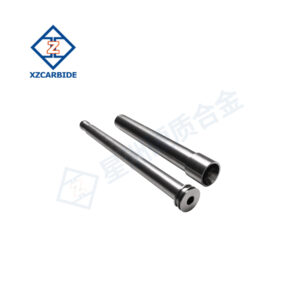

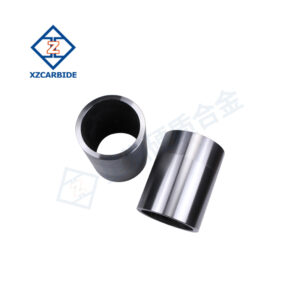

Product Characteristics

- High abrasion resistance: Cemented carbide valve stem has excellent abrasion resistance, which can maintain the performance and prolong the service life under harsh working conditions.

- Corrosion resistance: Cemented carbide material has good resistance to most liquids and corrosive media.

- High precision: Cemented carbide valve stem has high dimensional precision and specified surface roughness to ensure sealing and operational reliability.

- Resistant to high temperature and high pressure: Able to achieve complete sealing under high temperature and high pressure, suitable for a variety of harsh industrial applications.

- Multi-specification options: A wide range of specifications and sizes are available to meet the needs of different valves and working conditions.

- High strength: High strength design ensures no deformation under high pressure conditions and maintains the sealing performance of the valve.

Applications

Widely used in petroleum, chemical, natural gas, electric power, metallurgy and other industries on the valve equipment. Especially in the harsh working environments such as oil drilling and deep-sea drilling, the carbide valve stem becomes an indispensable key component with its excellent performance.

- Oil drilling: Used for ball valves and ball seats in oil drilling to improve the sealing and durability of pumping pumps.

- Deep sea drilling: Used in ball valves and ball seats for deep sea drilling pumps to ensure reliability in high pressure and highly corrosive environments.

- Chemical industry: Used in piping systems handling corrosive media to provide efficient sealing and operation.

- Machine building: Used in mechanical components requiring high precision and high wear resistance.

Instructions for Use

- Choose the right model: Select the appropriate specification of carbide valve stem according to the working environment of the valve and the nature of the medium.

- Correct installation: Ensure that the valve stem is correctly installed in the valve, and carry out the necessary tightening and alignment.

- Regular inspection: Regularly check the wear and corrosion of the valve stem, and replace the worn or damaged stem in time to ensure the normal operation of the valve.

- Maintenance: Regular maintenance of the valve and valve stem to keep them clean and lubricated to prolong the service life.

- Safe operation: Wear appropriate protective equipment when installing and maintaining the valve stem to ensure safe operation.

Reviews

There are no reviews yet.