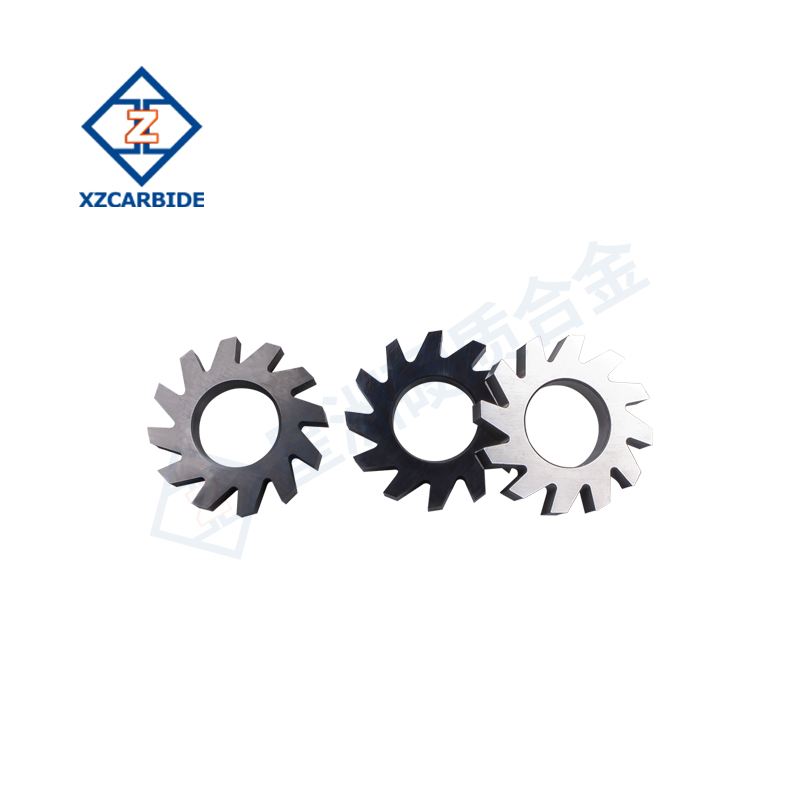

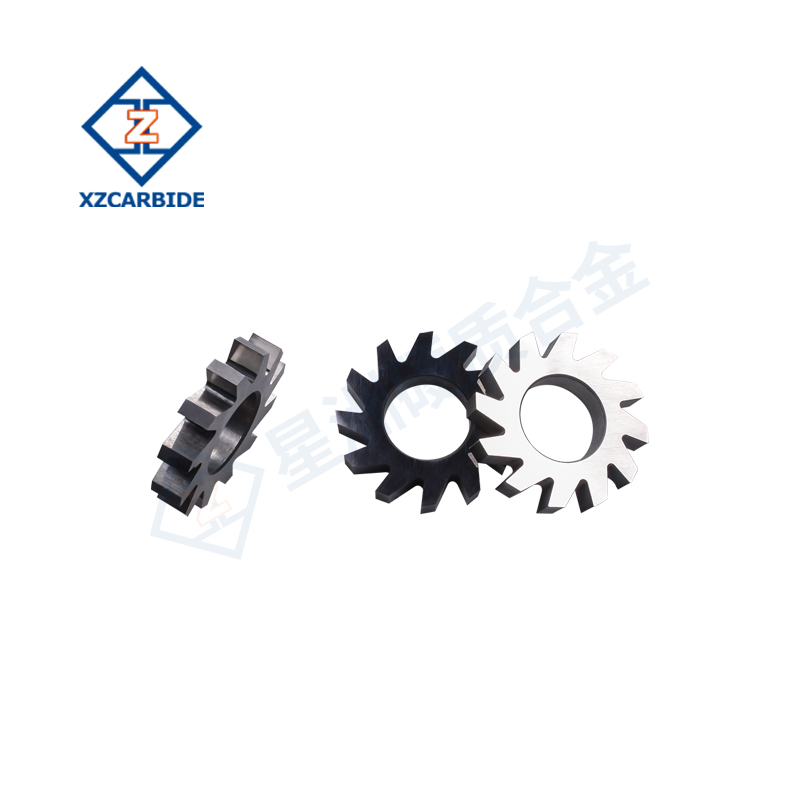

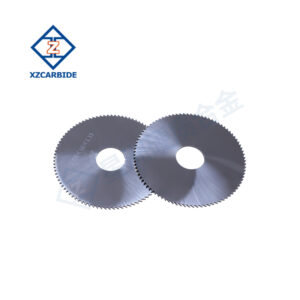

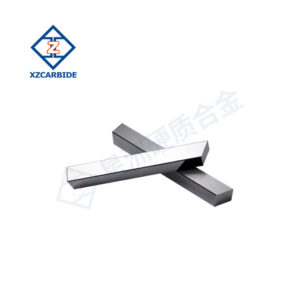

Main Features

- High hardness and wear resistance: The high quality cemented carbide material has extremely high hardness and wear resistance.

- High precision: Capable of high precision gear machining, ensuring that gear tooth shape and dimensions meet strict standards.

- Durability: Long service life, reducing the frequency of replacement and increasing productivity.

- Adaptability: Suitable for machining gears of many different materials and hardness.

- Variety of sizes and specifications: A wide range of sizes and specifications are available to meet the needs of different application scenarios.

Precautions

- Determine the specific application requirements, such as material, tooth shape, size, etc., when selecting carbide gear cutting tools.

- Ensure that the tool is properly installed on the machine tool to avoid damage to the tool or deviation in accuracy due to improper installation.

- Reasonably select the cutting speed, feed rate and depth of cut to avoid tool wear or damage due to improper parameters.

- Regularly check tool wear, timely replacement or resharpening of tools to ensure machining quality.

- Keep the machine tool in good maintenance condition to ensure that the tool runs smoothly and reduce tool damage caused by machine tool problems.

- Clean the tool in time after each use to remove chips and residues and prevent the tool from rusting or damage.

- Keep the tool in a dry, clean and impact-free environment when not in use to avoid contamination or damage to the tool.

Applications

- Automotive: Manufacture precision gear components such as automotive transmissions, differentials, engine timing gears, etc.

- Aerospace: Processing of high performance transmission gears

- Machinery manufacturing: Machining of gear components for machine tools, pumps, compressors and other machinery and equipment

- Industrial automation: Automation equipment and robots in the transmission system of the precision gear components

- Electric power: Gear processing for power generation equipment and power transmission equipment, such as gearboxes for wind turbines

Отзывы

Отзывов пока нет.