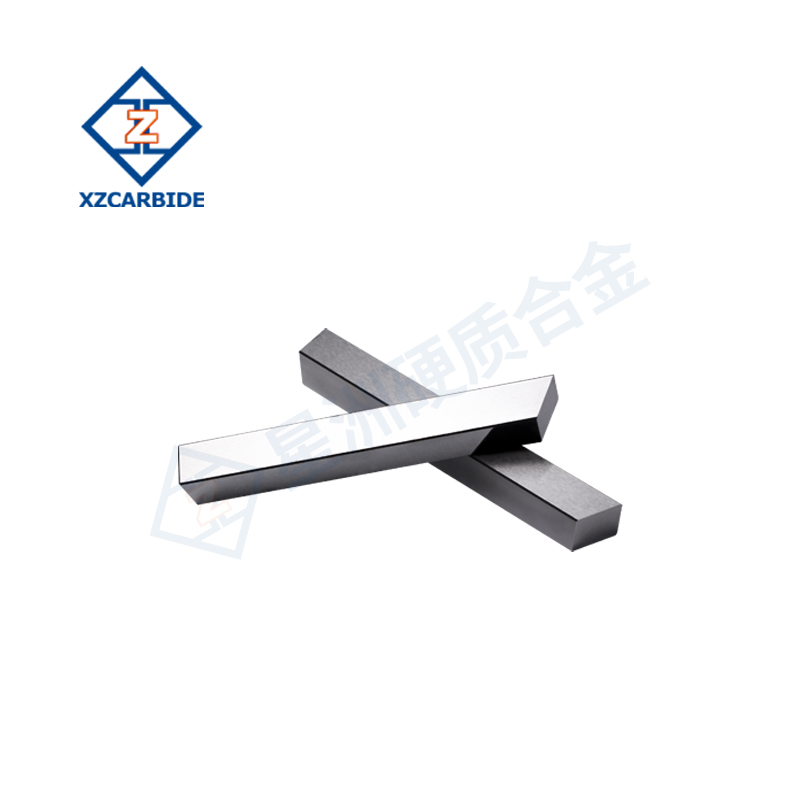

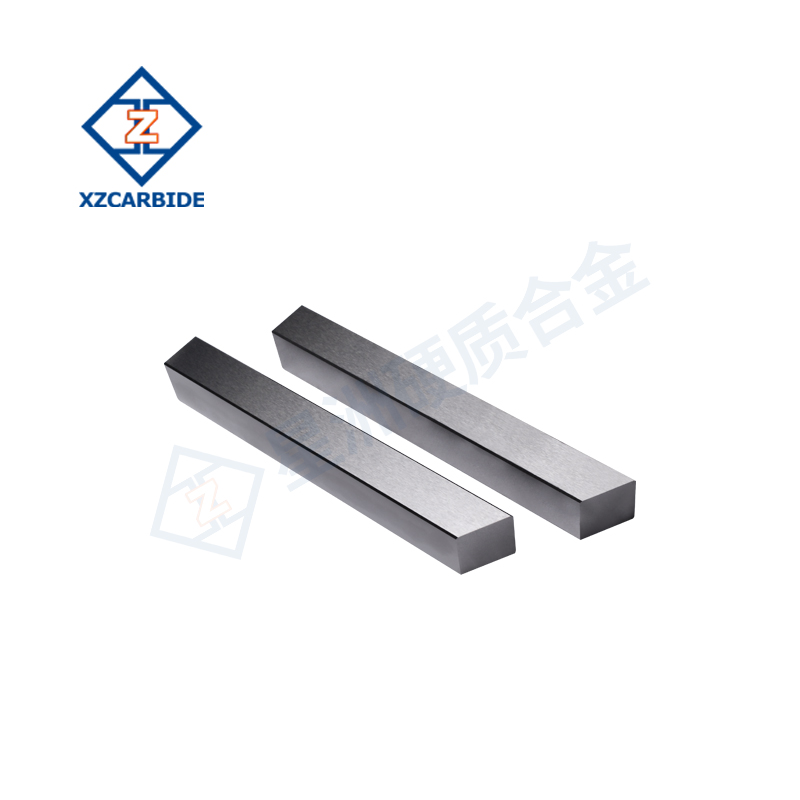

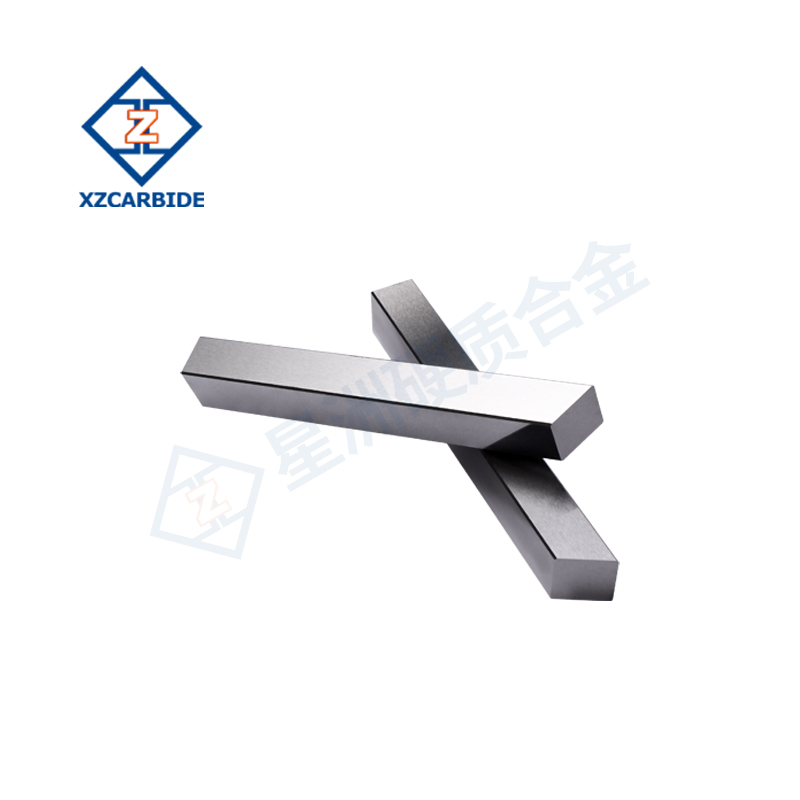

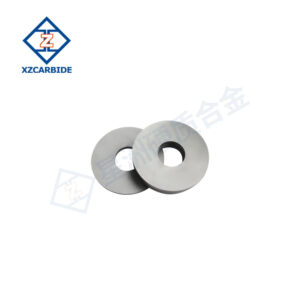

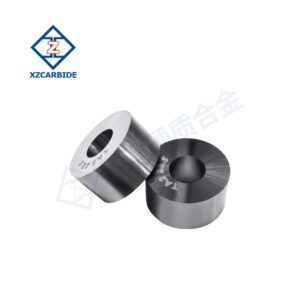

Product Features

- High-precision design: High-precision CNC machining technology is adopted to ensure that the contours and dimensions of the forming cutter are precise and meet the most stringent tolerance requirements.

- High-quality materials: High strength and wear resistant cemented carbide or high speed steel is selected as the base material, and after special heat treatment process, the hardness and service life of the tool are enhanced.

- Efficient cutting: Unique cutting edge design and coating technology reduces cutting resistance, improves cutting efficiency, while reducing energy consumption and machining costs.

- Stability and durability: Optimized tool structure and balance design ensures stability at high speeds, reduces vibration and noise, and extends tool life.

- Wide applicability: Suitable for various machine tools and machining systems, supporting automated production, improving productivity and flexibility.

Technical Parameters

| Material | Tungsten carbide or HSS |

| Size | Customized according to customer needs |

| Accuracy | ±0.005mm (or higher) |

| Applicable RPM | Depending on tool type and material properties |

| Coating Type | Various coatings available |

| Applicable machine tools | CNC milling machines, machining centers, CNC lathes, etc. |

Applications

- Mechanical manufacturing

- Automotive parts processing

- Aerospace

- Mold and die making

Operation

- Follow the operation manual to install and use the forming cutter correctly.

- Pay attention to the reasonable selection of cutting parameters to ensure machining quality and tool life.

Maintenance and Care

- Clean the tool regularly to remove chips and coolant residues.

- Ensure that the tool is dry, clean and properly stored when storing.

Avaliações

Ainda não existem avaliações.