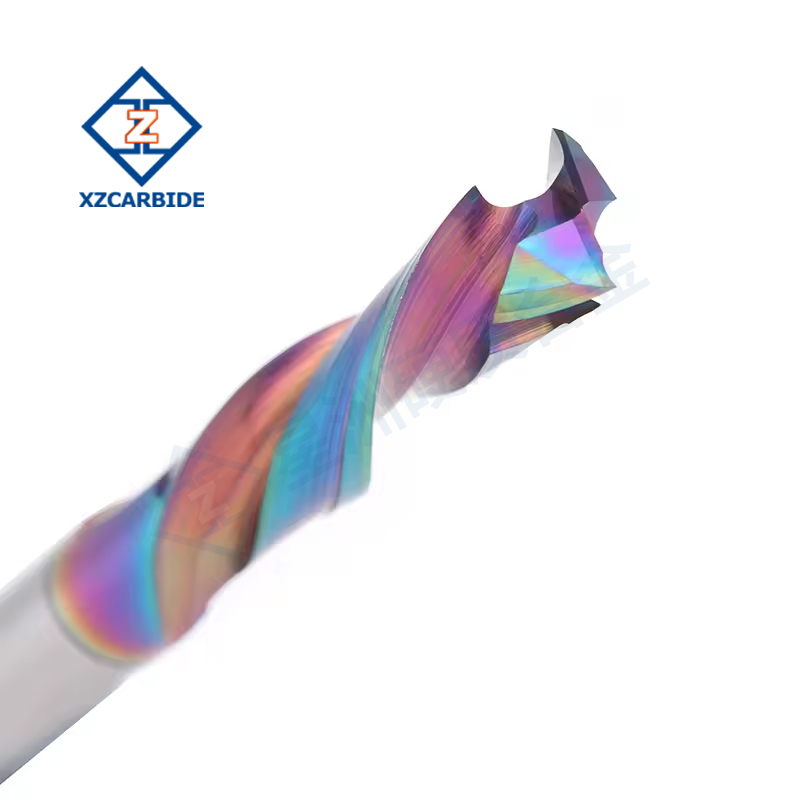

Key Features

- Reduced Tearing: The upper and lower cutting inserts are designed to minimize tearing of the material surface during the cutting process, ensuring smooth and clean cutting edges.

- Efficient Cutting: The compression spiral router bit efficiently removes wood chips through shearing action and is able to handle faster feed rates.

- Double Clean: These cutters combine top and bottom cutting to ensure that both sides of the material are free of burrs, making them suitable for double-sided veneer materials.

- Durability: Usually made of solid carbide for extreme durability and long life.

- Reduced Vibration: The spiral design helps to reduce vibration and provides a smoother cutting process.

- Customized Service: Compression spiral router bit are customized in different sizes and shapes to meet specific application requirements.

Technical Parameter

| Material | Solid carbide for excellent cutting performance and wear resistance |

| Size | Regular or customized |

| Cutting Methods | Combination of up-cutting and down-cutting ensures that both sides of the material are burr-free |

| Coating | Various coatings are available depending on the specific application |

| Applicable Materials | Laminate, hardwood, softwood, double-sided veneer, and many other materials |

Typical Applications

- Laminate Processing: Reduce upper and lower tearing effectively

- Plywood Processing: Provide smooth cutting edges

- Composite Material Processing: Precision machining to minimize edge burrs

- Furniture Manufacturing: Ensure cutting quality and efficiency

Avaliações

Ainda não existem avaliações.