Key Features

- High Hardness and Wear Resistance: The carbide material ensures a significantly longer tool life.

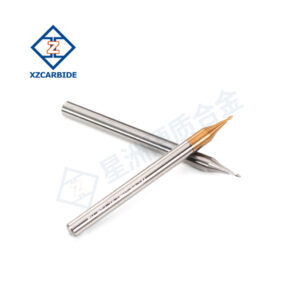

- Precision Machining: Suitable for various precise chamfering needs, ensuring smooth edges and high-quality surfaces on processed workpieces.

- Wide Range of Applications: Applicable for chamfering steel, stainless steel, aluminum alloys, copper, and various other materials.

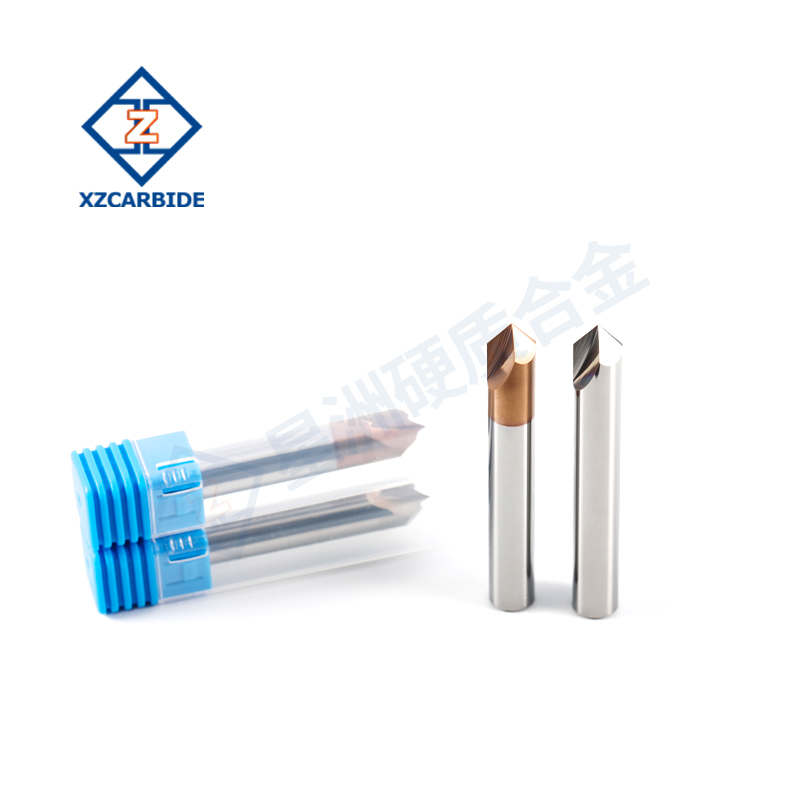

- Various Specifications Available: Provides chamfering tools with different angles and sizes to meet diverse machining requirements.

- High Efficiency: Maintains stable cutting performance under high-speed machining conditions, greatly improving production efficiency.

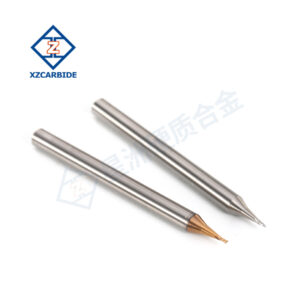

Product Specifications

| Material | Tungsten carbide |

| Chamfer Angle | 30°、45°、60°, etc. |

| Tool Diameter | 3-20 mm |

| Tool Length | 50-150mm |

| Number of Flutes | 1-4 flutes |

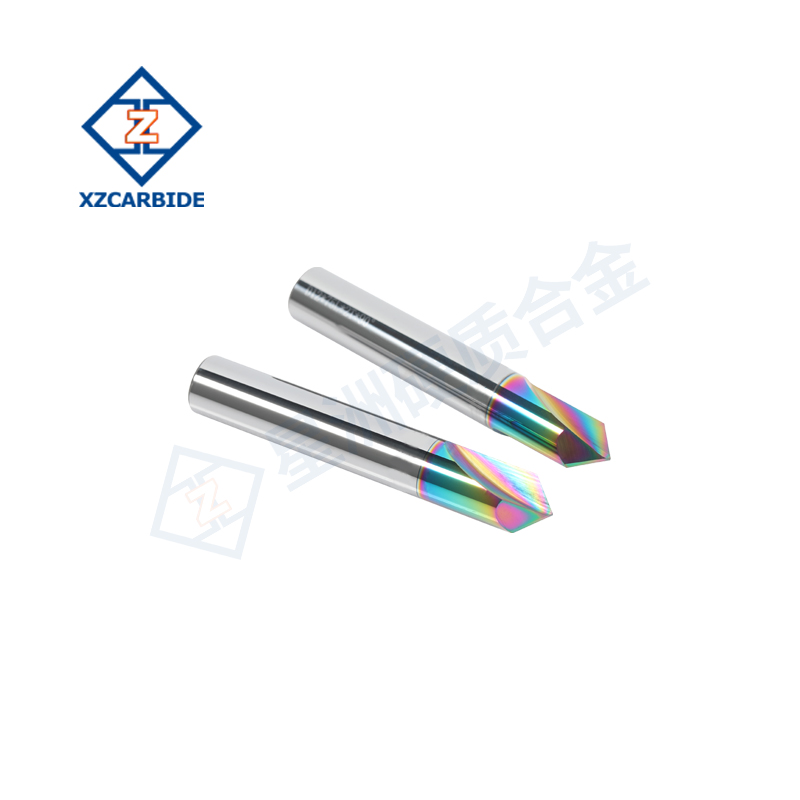

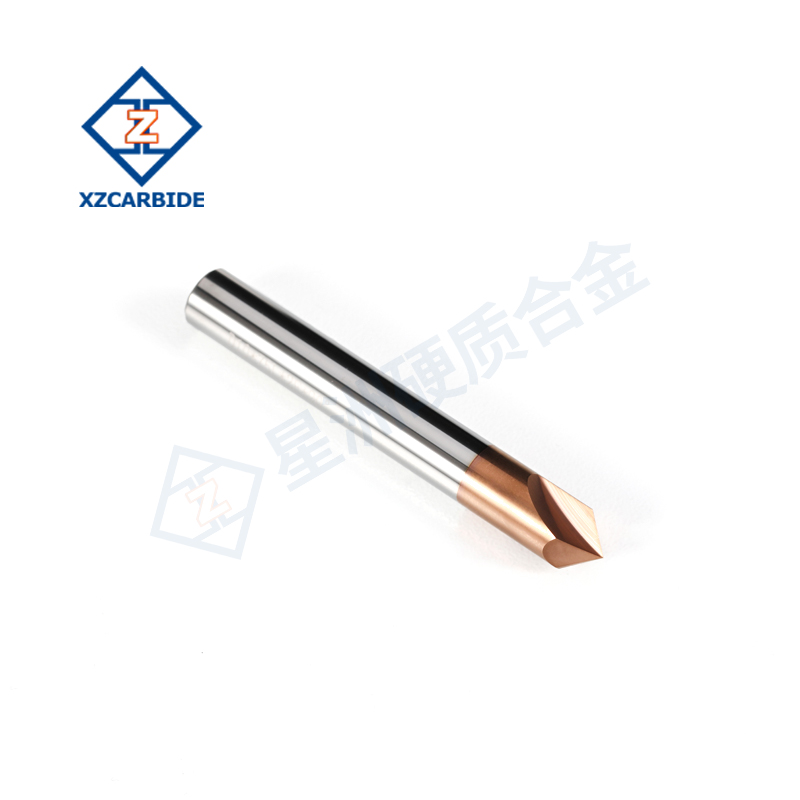

| Coating | TiN, TiAlN, DLC available |

Field of Application

- Machining: Used for chamfering and deburring of mechanical parts.

- Automotive industry: Edge treatment in the manufacture of automotive parts.

- Aerospace: For machining high-precision parts.

- Mold Manufacturing: Used in the process of mold manufacturing and finishing.

Usage Recommendations

- Select Appropriate Speed and Feed Rate: Choose the proper speed and feed rate according to the material and machining requirements to ensure optimal cutting results.

- Regular Inspection and Maintenance: Regularly check the wear of the tool and replace or regrind it in time to ensure machining precision and tool life.

- Use Coolant: Applying coolant during machining helps reduce cutting heat, improve machining quality, and extend tool life.

Avaliações

Ainda não existem avaliações.