Customized Service

We provide the following customized services:

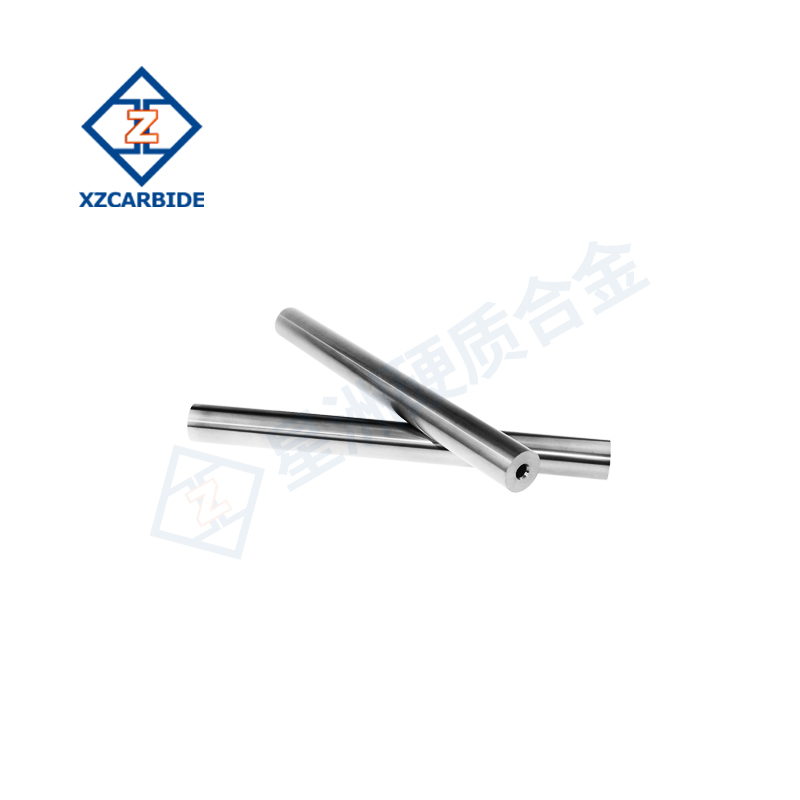

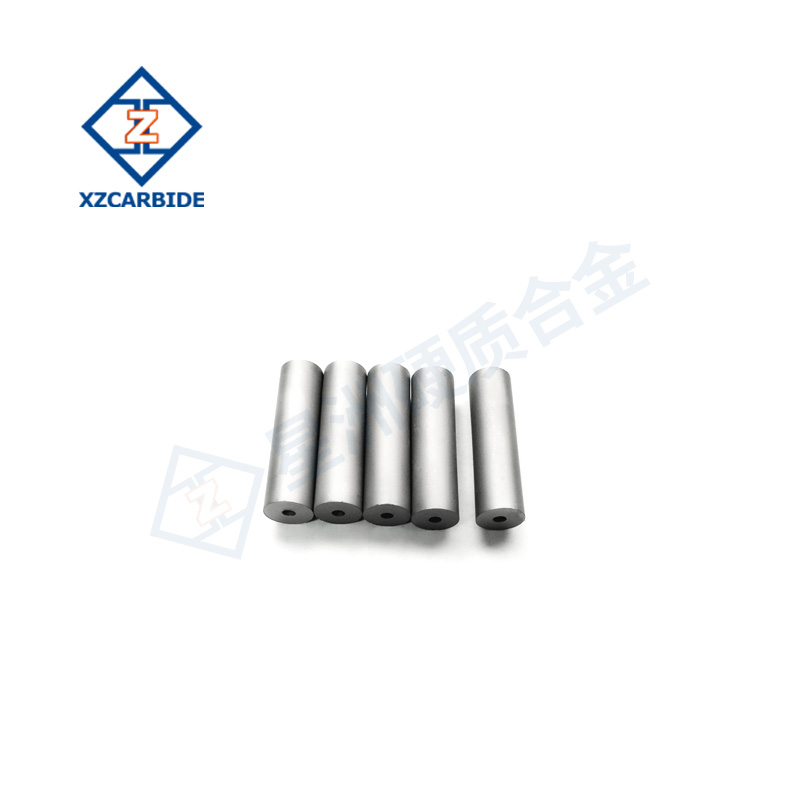

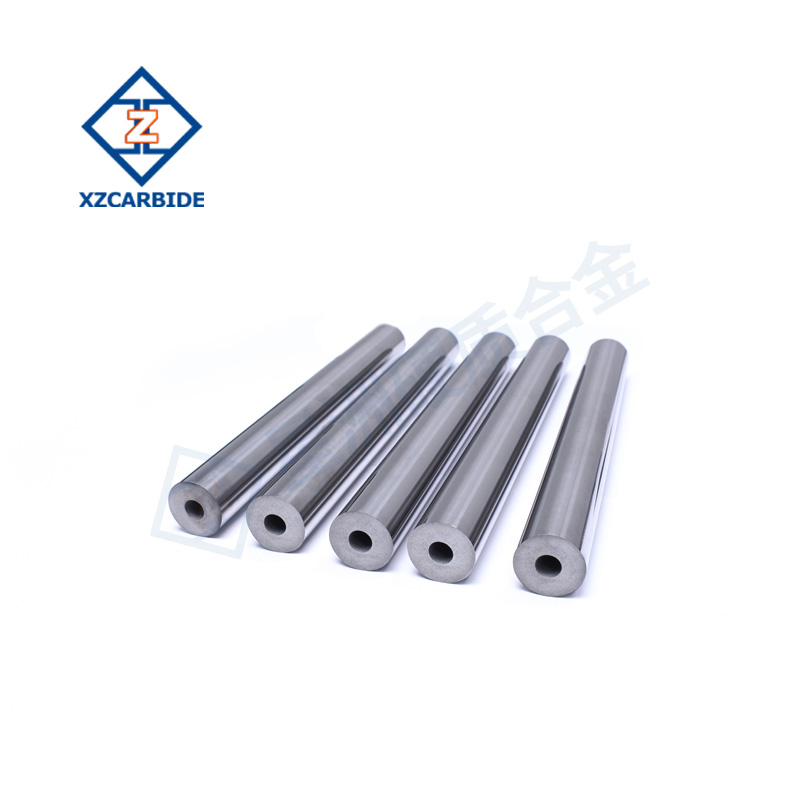

- Size customization: Provide different diameters and lengths of carbide single hole round rods according to customers’ requirements.

- Material customization: Select tungsten-cobalt alloy with different ratios according to the usage environment.

- Hole diameter customization: Customize the center hole with different diameters according to the installation requirements.

Common Used Grades

| Grade | InternationalStandards | Density(g/cm3) | Hardness(HRA) | Bending Strength(MPa) | Applications |

YG8 | K30 | 14.8 | 89.5 | ≥3500 | High strength, impact resistance and shock resistance, better than YG6. Suitable for making forming knives and wear-resistant parts. |

YG11 | K40 | 14.4 | 88.5 | ≥3650 | Suitable for making stamping molds. |

NT15 | K40 | 14.0 | 87.5 | ≥3800 | Suitable for making stamping dies (processing silicon steel sheets), wear-resistant parts, etc. |

YG20 | K30 | 13.5 | 85.5 | ≥4200 | High strength, suitable for making progressive dies and other stamping dies. |

YG6X | K10 | 14.9 | 91.5 | ≥3200 | Fine-grained alloy with good wear resistance and is suitable for making forming knives and wear-resistant parts. |

YL10.2 | K10 | 14.5 | 92 | ≥3850 | Ultra-fine grain alloy with high wear resistance, bending strength, anti-adhesion ability and pad strength. It is suitable for low-speed rough machining. |

Other grades are available on request | |||||

Avaliações

Ainda não existem avaliações.