In the field of precision machining, choosing the right tool is critical to creating high quality products. With their unique design and excellent performance, long neck radius end mills are indispensable tools for mold making and machining of complex parts.

Overview

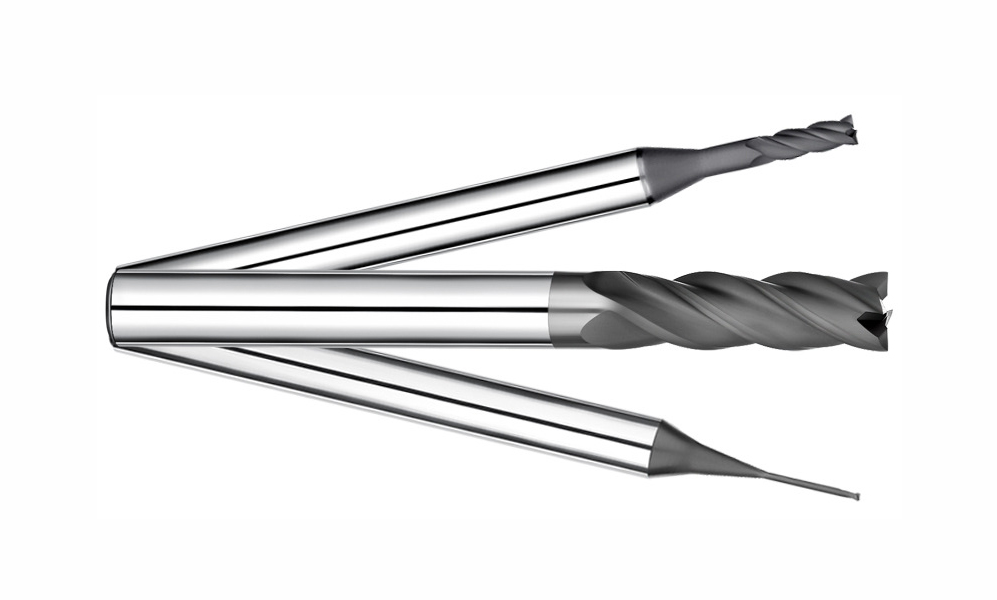

The long neck radius end mill is a milling cutter with a special structure, which is mainly used to realize high precision and complex contour machining. Its main features include a long neck design and a rounded nose compared to conventional end mills. The long neck design provides better rigidity and deeper cutting ability, while the rounded edges help reduce burrs and improve surface finish. Not only does this design allow the tool to machine in deep cavities, tight areas and hard-to-reach parts, it also reduces stress concentrations during the cutting process, extends tool life and improves machined surface quality.

In terms of material, long neck radius end mills usually use high quality cemented carbide as the base material. Cemented carbide not only provides excellent hardness and wear resistance, but also maintains stable cutting performance at high rotational speeds. In order to further enhance the durability and cutting efficiency of the tools, many long neck radius end milling cutters also adopt advanced coating technology, such as titanium nitride and tungsten carbide, which effectively extends the service life of the tools.

Manufacturing Processes and Technologies for Long Neck Radius End Mills

The manufacturing process and technology of long neck radius end mills is the cornerstone of their outstanding performance and precision. This process combines advanced results from different fields, such as high-precision machining, material science and coating technology to ensure the stability and durability of the tool in complex machining environments. The following is a detailed analysis of the manufacturing process and technology for long neck radius milling cutters:

Precise material selection and pretreatment

Material selection: According to the machining requirements, high performance materials such as HSS and cemented carbide are selected as the substrate. These materials have excellent hardness, wear resistance and impact resistance, and are the basis for manufacturing high-quality milling cutters.

Pre-treatment: The selected materials are subjected to rigorous pre-treatment, including stress relief annealing, surface cleaning and other steps to eliminate residual stresses within the material and improve its machinability and stability.

Precision molding on CNC machining centers

3D modeling: CAD/CAM software is used for 3D modeling of the tool to accurately design the shape, size and cutting edge angle of the tool to ensure that the tool meets the machining requirements.

CNC machining: The designed 3D model is imported into the CNC machining center, and the tool is accurately formed through high-precision CNC programming and machine operation. This process includes roughing, semi-finishing and finishing stages, each of which requires strict control of machining parameters and tool paths to ensure tool accuracy and surface quality.

Precision grinding and edge treatment

Edge grinding: High-precision grinding machine is used to grind the cutting edge of the tool to ensure that the edge is sharp, flat and the angle is accurate. During the grinding process, the quality of the edge is constantly checked and the grinding parameters are adjusted in time to achieve the best results.

Rounded corners: The special rounded corner grinding process creates a smooth transition to rounded corners at the cutting edge of the tool. This design not only reduces friction and vibration during the cutting process, but also improves the finish of the machined surface.

Coating application

Coating selection: Select the appropriate coating material based on the tool’s operating environment and machining requirements. Common coating materials include hard coatings such as titanium nitride and tungsten carbide, as well as special coatings with self-lubricating and high-temperature resistant properties.

Coating process: PVD, CVD and other advanced coating processes are used to evenly and densely attach the coating material to the tool surface. During the coating process, the temperature, pressure and other process parameters are strictly controlled to ensure the coating quality.

Quality inspection and evaluation

Dimensional inspection: Using high-precision measuring instruments to accurately measure the size, shape and angle of the tool to ensure that the tool meets the design requirements.

Performance evaluation: Evaluate the cutting performance, durability and stability of the tool by means of cutting tests and wear resistance tests. Based on the evaluation results, feedback and optimization of the manufacturing process is carried out to improve product quality.

Advantages of Long Neck Radius End Mills

Deep cavity machining capability

The long neck design of the long neck radius milling cutter makes it easy to handle deep cavities and confined areas. This is especially true in mold and die manufacturing, automotive parts and other areas where deep cavities are required. Whether you are machining complex mold cavities or deep holes, long-neck radius end mills provide excellent performance.

Reduced stress concentrations

The rounded corner design is one of the highlights of the long neck radius cutters. Conventional sharp corners tend to create stress concentrations during the cutting process, resulting in increased tool wear and reduced workpiece surface quality. The rounded corner design effectively disperses the cutting stress, reduces tool wear and extends tool life. At the same time, this design also improves the surface finish of the machined surfaces and ensures the high quality of the workpiece.

High wear resistance and thermal stability

Long-neck radius milling cutters are usually made of high-hardness materials, such as carbide. These materials have excellent wear resistance and thermal stability, allowing the tools to perform well when machining high hardness materials. Whether it’s hardened steel or titanium alloys, long neck radius cutters are able to handle them with ease, ensuring machining accuracy and efficiency.

Limitations of Long Neck Radius End Mills

Despite the many advantages of long neck radius end mills, there are still some limitations in practical applications:

Higher cost

Long neck radius cutters are usually manufactured using high quality carbide materials and advanced coating technology, which results in higher manufacturing costs. As a result, they are also relatively expensive and can be a challenge for companies with limited budgets.

Specific application limitations

While long neck radius milling cutters perform well in deep cavities and confined areas, they may not be the best choice for certain specific applications. For example, for large flat surfaces or roughing tasks, other milling cutter types may be more suitable.

Technical Specifications for Long Neck Radius End Mills

| Blade Diameter (D) | The primary parameter when selecting an end milling cutter which directly affects the size and scope of the machining. When selecting, the dimensions of the workpiece and the required depth of machining should be taken into account. |

| Radius Size (R) | Determines the minimum radius of the corner that can be machined by the milling cutter. For precision machining, a highly accurate radius size ensures that the machining accuracy meets the design requirements. |

| Blade length (ℓ) | Relates to the depth of cut of long neck radius end mills. Longer inserts allow for deeper cuts, but they also require the machine to provide enough rigidity to prevent vibration. |

| Number of slots | Affects cutting efficiency and chip removal capacity. Generally speaking, the more slots, the higher the chip removal efficiency, but also higher requirements for machine torque. Commonly, the number of slots are 2 slots and 4 slots. |

| Overall length (L) | Including shank and insert lengths, you need to ensure that the milling cutter can reach the machining area of the workpiece. At the same time, take into account the travel limitations of the machine tool. |

| Shank diameter (d) | The part of the milling cutter that connects to the machine tool needs to be matched to the spindle of the machine. There are a variety of common shank sizes, and the right shank size ensures the stability of the tool. |

| Coating materials | The performance of milling cutters can be significantly improved, for example, TiAlN coatings provide high hardness and wear resistance and are suitable for machining hard materials. |

| Shank type | These include straight shanks, taper shanks, etc. The selection should take into account the type of machine tool spindle and the required clamping stability. |

Application Areas

Mold manufacturing

In the mold manufacturing industry, long neck radius milling cutters are widely used for precision machining of mold cavities. Their high accuracy and surface quality make them the tool of choice for mold makers. Not only does it improve machining efficiency, but it also greatly reduces mold dressing time.

Aerospace

The aerospace industry has extremely high requirements for machining precision and complex shapes. Long-neck radius milling cutters meet the stringent standards of this industry with their deep-cavity machining capabilities and superior surface quality. Whether it’s an aircraft component or a spacecraft structure, long neck radius cutters provide a reliable solution.

Medical devices

The manufacture of medical devices requires extreme precision and finish to ensure product safety and effectiveness. Long neck radius end mills excel at machining precision parts, helping medical device manufacturers improve product quality and meet the industry’s stringent technical requirements.

Conclusion

Long-neck radius milling cutters provide strong support for high-precision machining due to their unique design and excellent performance. Whether in mold manufacturing, aerospace, or medical devices, long neck radius end mills show excellent performance. By choosing the right tool, you can significantly improve machining efficiency, ensure product quality, and further enhance market competitiveness.

In the future, as technology continues to advance and manufacturing continues to grow, the range of applications for long neck radius end milling cutters will expand even further. Manufacturers can continue to improve the tool material and coating technology, reduce costs, improve performance, so that more companies benefit.

In short, long neck radius end mills are not only indispensable high-precision machining tools in modern manufacturing, but also an important force to promote the technological progress of manufacturing. Through continuous innovation and optimization, long neck radius end milling cutters will bring significant benefits and competitive advantages to more industries and enterprises in the future.