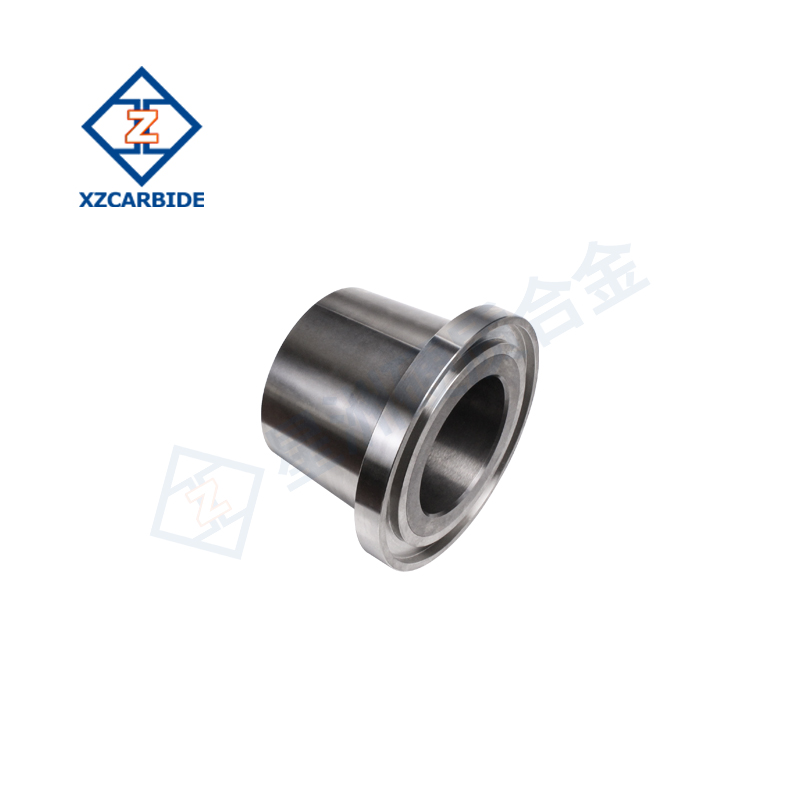

Technical Parameters

| Material | Premium quality tungsten carbide |

| Hardness | Typically in the range of 14.4 – 15.0 g/cm³ |

| Bending Strength | Usually between 600 – 900 Mpa |

| Wear Resistance Index | ≥0.05 mm³ (ASTM G65 standard) |

| Surface Roughness | Ra 0.4 μm – Ra 0.8 μm |

| Operating Temperature | Up to 1000°C |

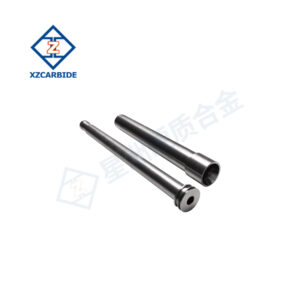

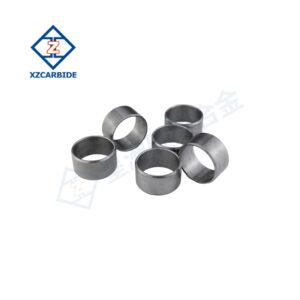

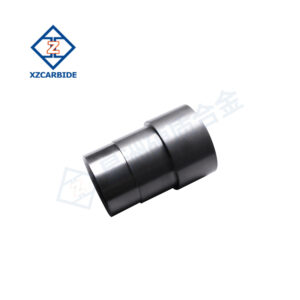

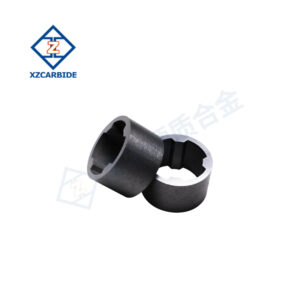

| Dimensions | Customized to specific needs, with diameters ranging from a few mm to hundreds of mm, and in a variety of lengths and shapes. |

| Surface Treatment | Precision grinding, polishing and other treatments to achieve the required dimensional accuracy and surface roughness. Some products can also be coated to enhance abrasion or corrosion resistance. |

Product Characteristics

- Material: High quality cemented carbide has extremely high hardness and wear resistance.

- High temperature resistance: Can maintain stable performance under high temperature environment.

- Corrosion resistance: Good corrosion resistance to acid, alkali and other chemical substances.

- Precision processing: Advanced processing technology is adopted to ensure dimensional accuracy and surface quality.

- Easy installation: Reasonable design, easy to disassemble and replace, reduce maintenance time.

- Strong adaptability: Suitable for various working environments, including high temperature, corrosive media and other harsh conditions.

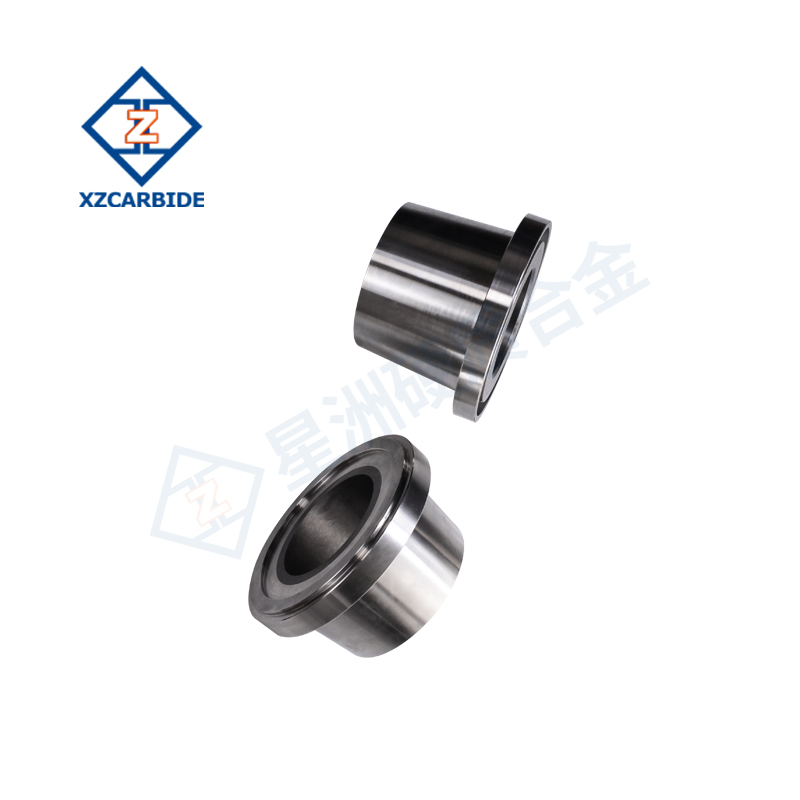

Applications

- Pumps and valves: Used to protect the contact surface between the shaft and the bearing housing to reduce wear and leakage.

- Machinery: Used in bearings, guide rails and other components to improve the efficiency of mechanical operation.

- Automobile: Used in engine, gearbox and other key components for wear protection.

- Metallurgy: Bearings and seals for high temperature and heavy load environments.

- Aerospace: Bearings and seals for engines, rockets and other high-precision equipment.

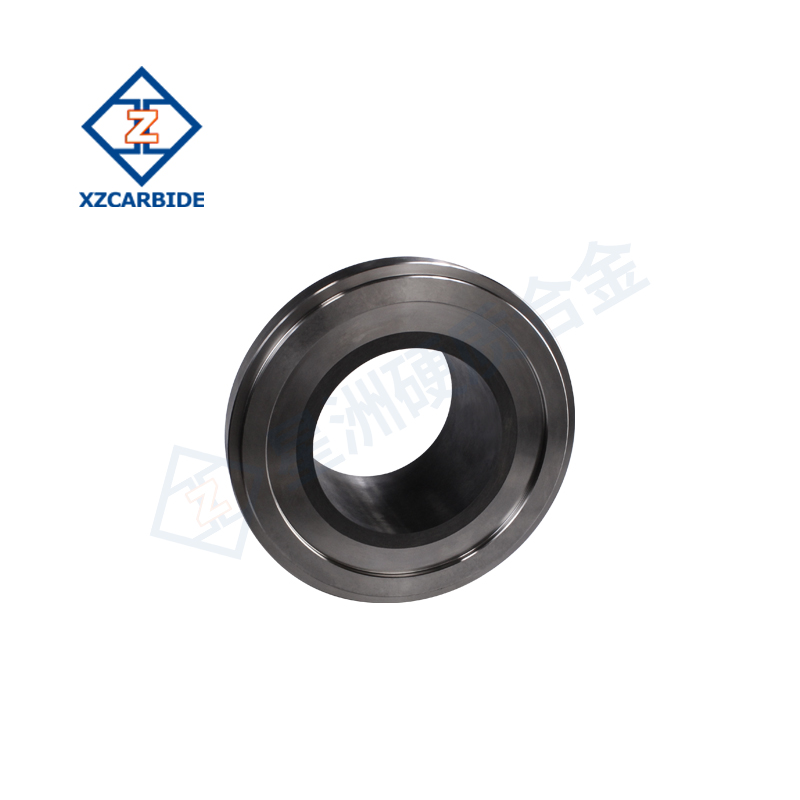

Installation Guide

- Preparation: Make sure the mounting surface is clean and free of oil.

- Measurement: Select the appropriate shaft sleeve size according to the specifications of the shaft.

- Installation process: Follow the instructions in the manual to ensure that the installation is secure.

- Inspection and confirmation: Check after installation to ensure that there is no looseness.

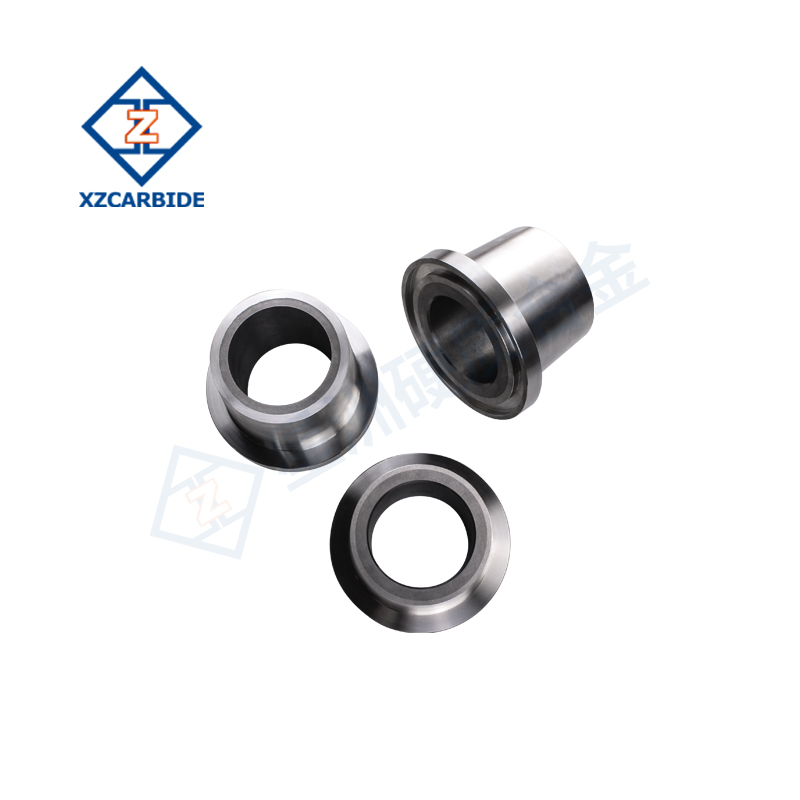

Maintenance

- Regular inspection: Regularly check the wear and tear of the shaft sleeve.

- Timely replacement: Replace the shaft sleeve in time when it is found to be seriously worn to avoid damaging the equipment.

- Cleaning and maintenance: Regularly clean the impurities attached to the shaft sleeve.

Reviews

There are no reviews yet.