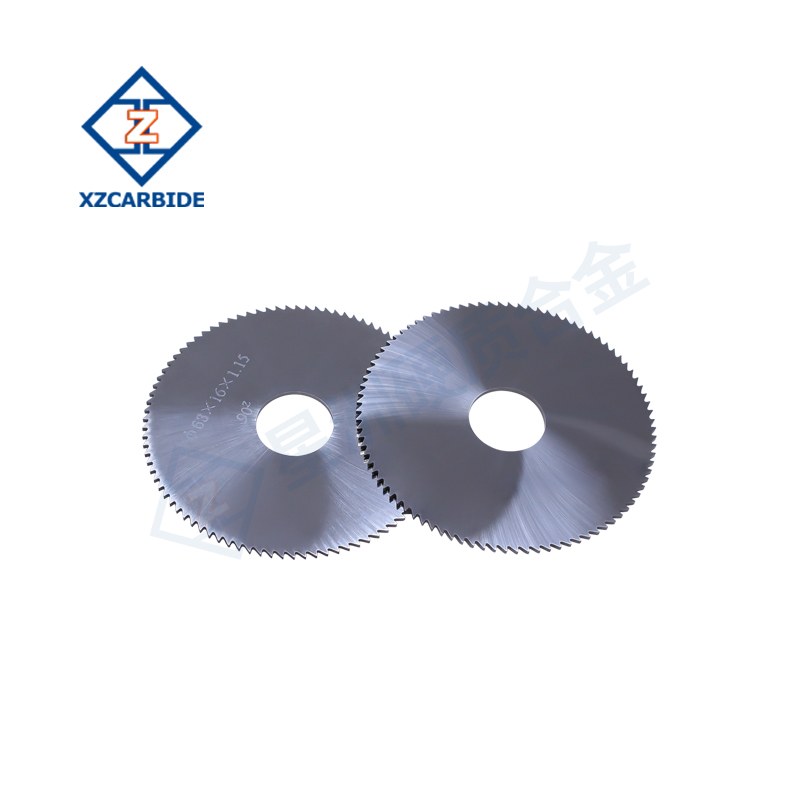

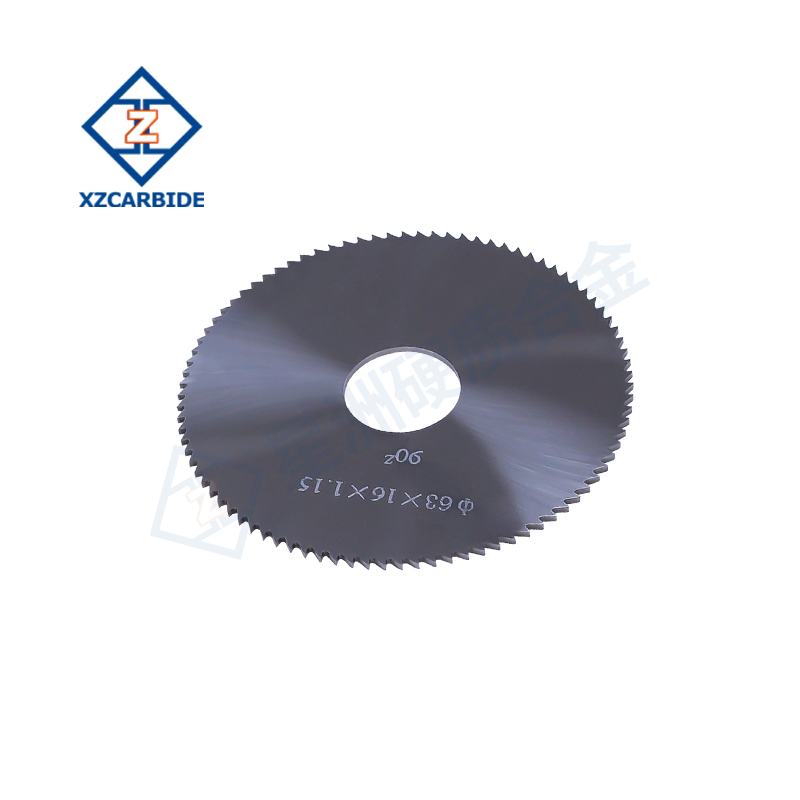

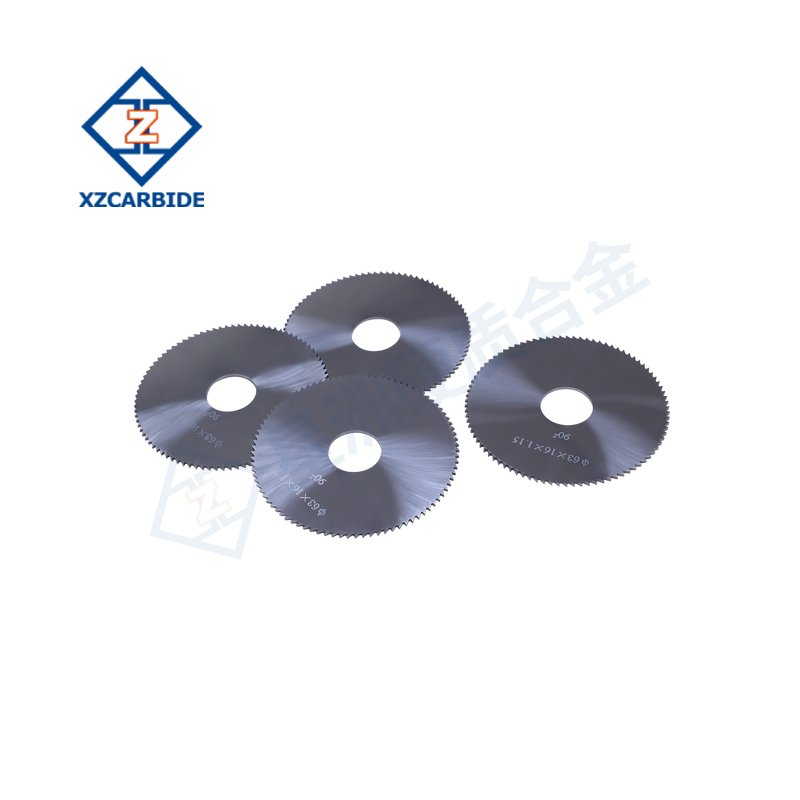

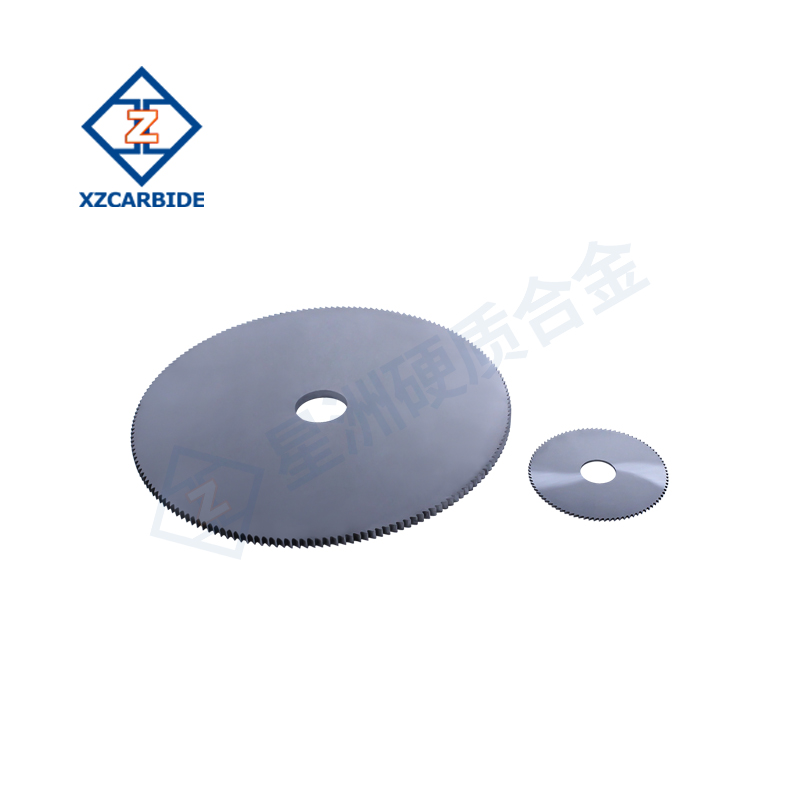

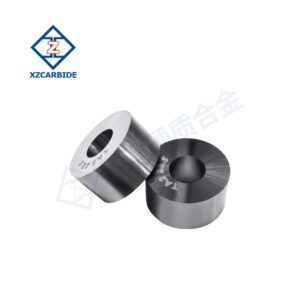

Basic Dimensions

|

Diameter (mm) |

Kerf | Bore | Tooth Number | Tooth Configuration |

| 200 | 3.2 | 30 | 36 | TCG or TT or ATB or Flat |

| 250-315 | 3.2 | 30 | 60 | TCG or TT or ATB or Flat |

| 300-315 | 3.2 | 30 | 96 | TCG or TT or ATB or Flat |

| 350 | 3.5 | 30 | 96 | TCG or TT or ATB or Flat |

| 350-400 | 4.4 | 30-80 | 48 | TCG or TT or ATB or Flat |

| 350-400 | 4.4 | 30-80 | 96 | TCG or TT or ATB or Flat |

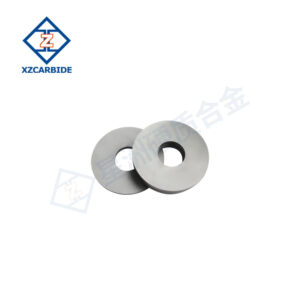

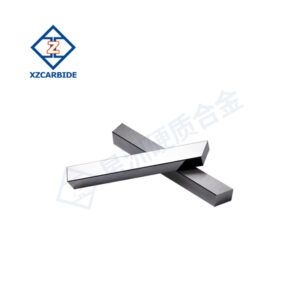

Features

- Made from 100% virgin raw material.

- Good toughness, superior wear resistance and high strength.

- Excellent performance and good wear corrosion resistance.

- HIP sintering, good compactness.

- High machining accuracy.

- Sharp edge and smooth surface.

- Strict products quality inspection.

- Used for steel, stainless steel, cast steel and cast iron cutting and processing.

- Stable quality and high efficiency.

Performance of Common Used Grades

| Grade | Performance | ||

| Density

(g/cm3) |

Bend Strength |

Hardness (HRA) |

|

| YG3 | 14.9-15.3 | ≥1180 | ≥90.5 |

| YG3X | 15.1-15.4 | ≥1300 | ≥91.5 |

| YG6X | 14.8-15.1 | ≥1560 | ≥91.0 |

| YG6A | 14.7-15.1 | ≥1580 | ≥91.0 |

| YG6 | 14.7-15.1 | ≥1670 | ≥89.5 |

| YG8 | 14.6-14.9 | ≥1840 | ≥89.0 |

| YT15 | 11.1-11.6 | ≥1180 | ≥91.0 |

| YT14 | 11.2-11.8 | ≥1270 | ≥90.5 |

| YT5 | 12.5-13.2 | ≥1430 | ≥89.5 |

| YW1 | 12.7-13.5 | ≥1180 | ≥91.5 |

| YW2 | 12.5-13.2 | ≥1350 | ≥90.5 |

Our Advantages

- Excellent wear resistance improves the blade life.

- Use low-temperature treatment technology to improve the internal micro-structure to avoid cracking.

- High precision, no glitches, and nice abrasion resistance.

- We use HIP sintered, fine grinding and polishing plating to reduce frictions when cutting, improved the accuracy and speed slitting greatly.

- Specialize in cutting all kinds of aluminum, metal and etc. Different grades are available.

Reviews

There are no reviews yet.