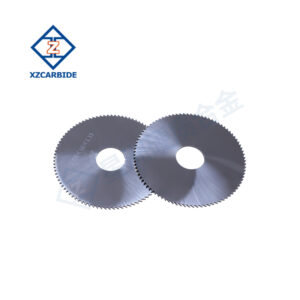

Product Highlights

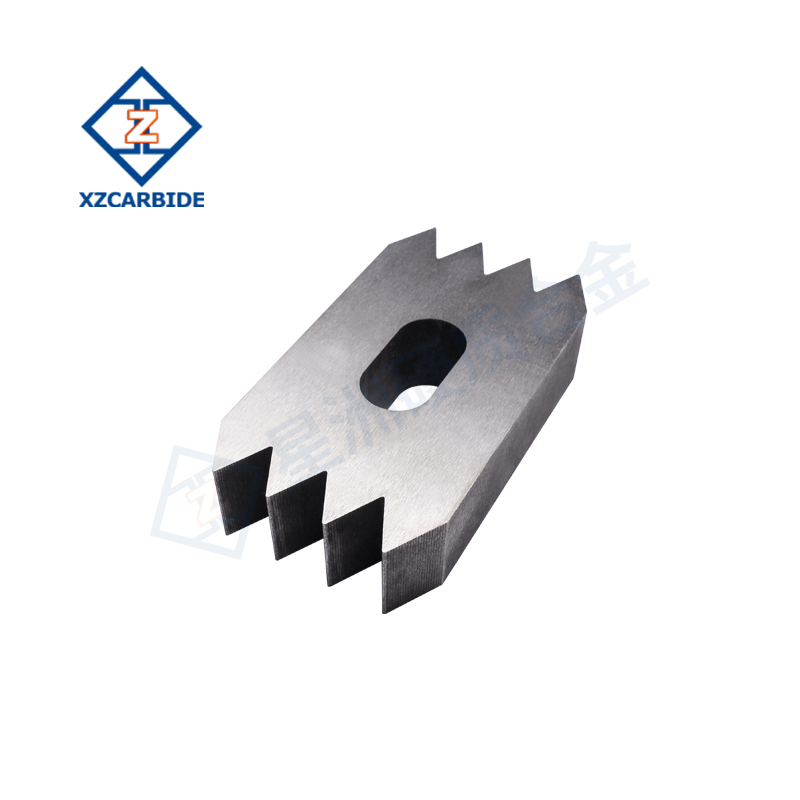

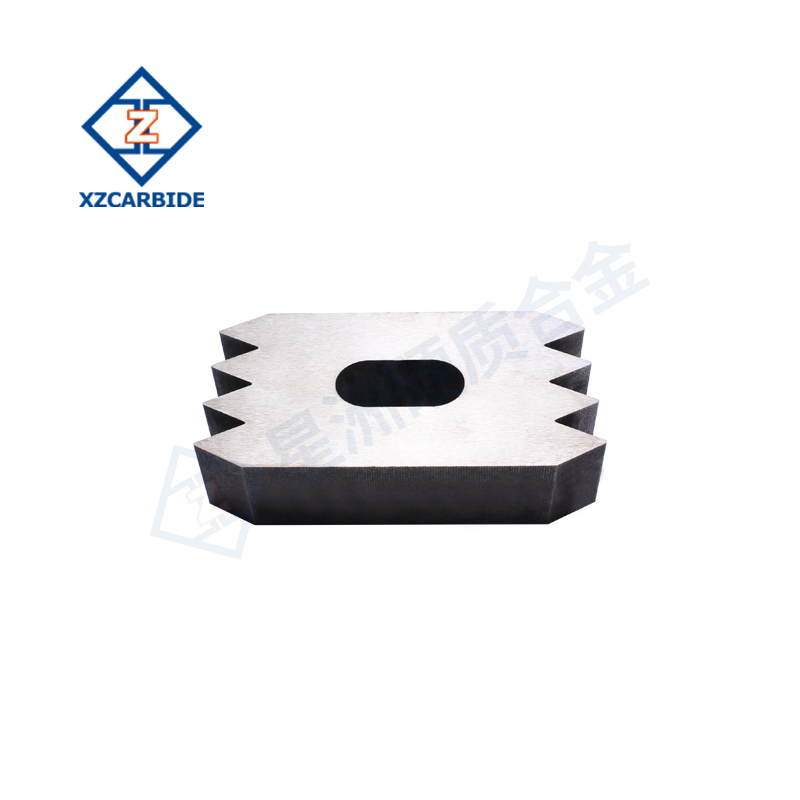

- Precision tooth design: Advanced CNC technology is used to ensure uniform and sharp tooth shape to enhance cutting accuracy and efficiency.

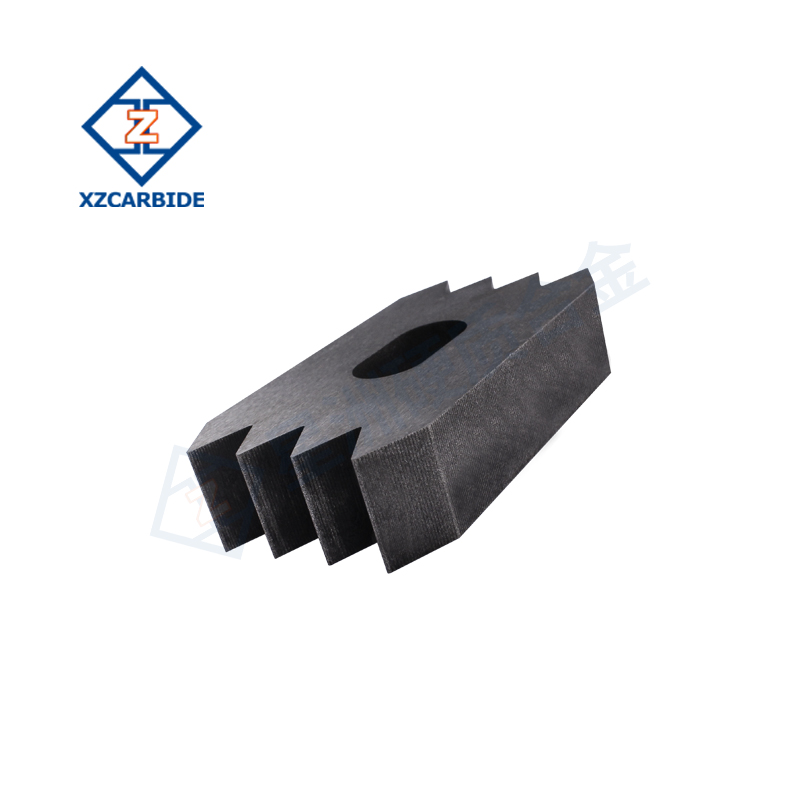

- High-quality materials: High strength materials such as high-quality alloy steel or cemented carbide are selected for their durability and excellent anti-wear performance.

- Wide applicability: Suitable for cutting and processing of various materials to meet the production needs of different industries.

- Balance optimization design: After precision dynamic balance test to ensure smooth operation, reduce vibration and noise, and extend the service life of the machine.

- Customized options: Customized tooth blades are designed and manufactured according to customers’ specific requirements to meet the special needs of different applications.

- Versatile applications: Suitable for various gear machining needs, including milling, cutting and shaping operations.

Common Used Grades

Grade | International Standards | Density (g/cm3) | Hardness (HRA) | Bending Strength (MPa) |

YG8 | K30 | 14.8 | 89.5 | ≥3500 |

| YG11 | K40 | 14.4 | 88.5 | ≥3650 |

NT15 | K40 | 14.0 | 87.5 | ≥3800 |

| YG20 | K30 | 13.5 | 85.5 | ≥4200 |

YG6X | K10 | 14.9 | 91.5 | ≥3200 |

| YL10.2 | K10 | 14.5 | 92 | ≥3850 |

Avis

Il n’y a pas encore d’avis.