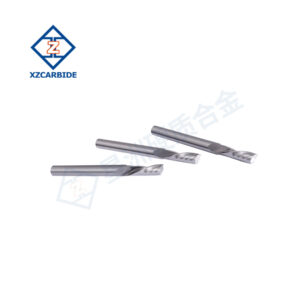

Product Features

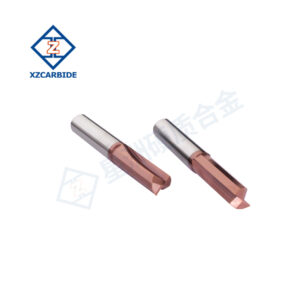

- Unique design: Specially designed for T-slot machining, it can complete T-slot milling tasks efficiently and accurately.

- Extensive application range: Suitable for T-slot machining of many materials, including but not limited to steel, cast iron, aluminum alloy and so on.

- Long life: Made of high quality materials and advanced technology to ensure the durability and service life of the tools.

- Customized service: Customized T-slot end milling cutter with special size and shape according to customer’s demand.

Product Parameter

| Matériel | Cemented carbide |

| Diameter | From a few mm to a few tens of mm |

| Length | Depending on diameter and specific application |

| Number of Blades | According to the width and depth of cut |

| Groove Type | Standard T-slots or customized T-slots |

| Shank | Straight or taper shank |

| Hardness | HRC 45/55/60/65 |

| Helix Angle | 25/30/35/45/55 |

Applications

- Machining: Used for milling T-slots in mechanical parts.

- Mould manufacturing: For T-slot machining of molds to improve the assembly precision of molds.

- Automotive industry: Used for T-slot machining of automotive parts, such as engine components.

- Aerospace: For T-slot machining of high-precision parts to ensure the reliability of the parts.

Guidelines for Use

- Select the material and specification of the T-slot end milling cutter that matches the material to be processed.

- Choose the appropriate milling cutter diameter and number of flutes for the size and depth of the T-slot.

- Follow the recommended cutting parameters, including cutting speed, feed rate and coolant usage.

Avis

Il n’y a pas encore d’avis.