Advantages

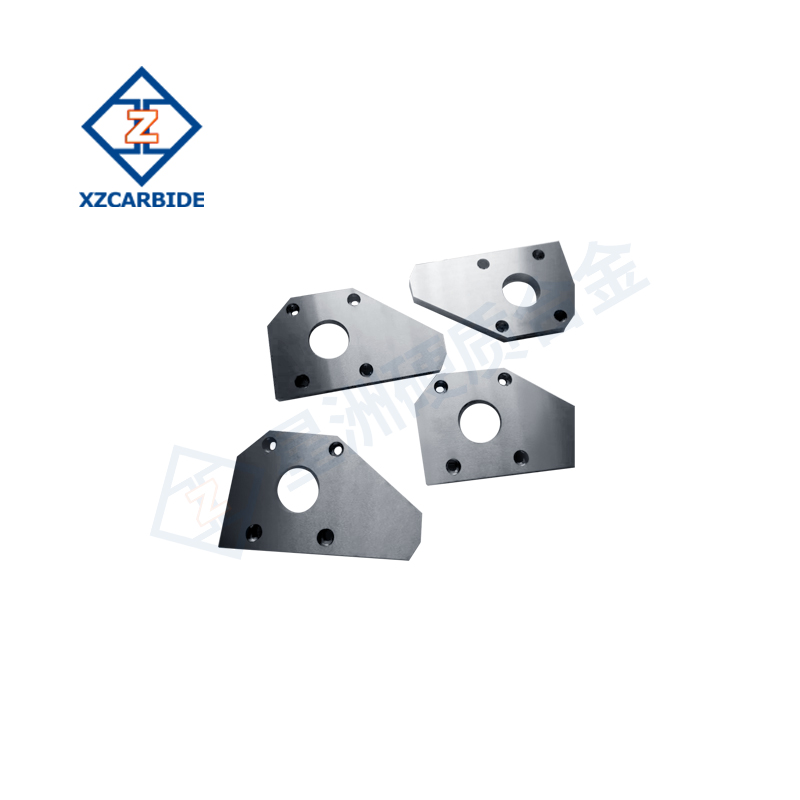

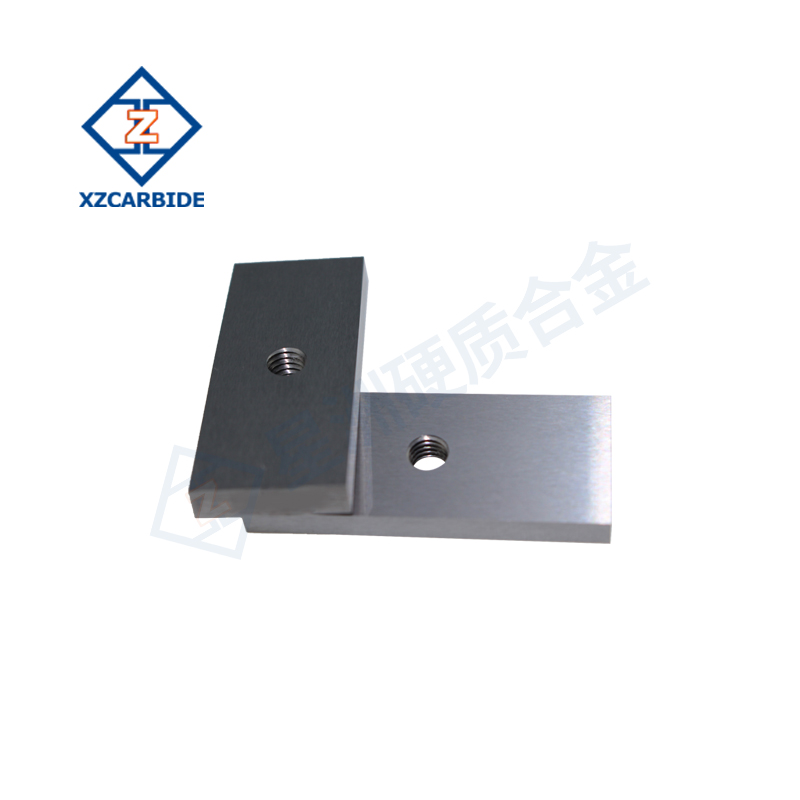

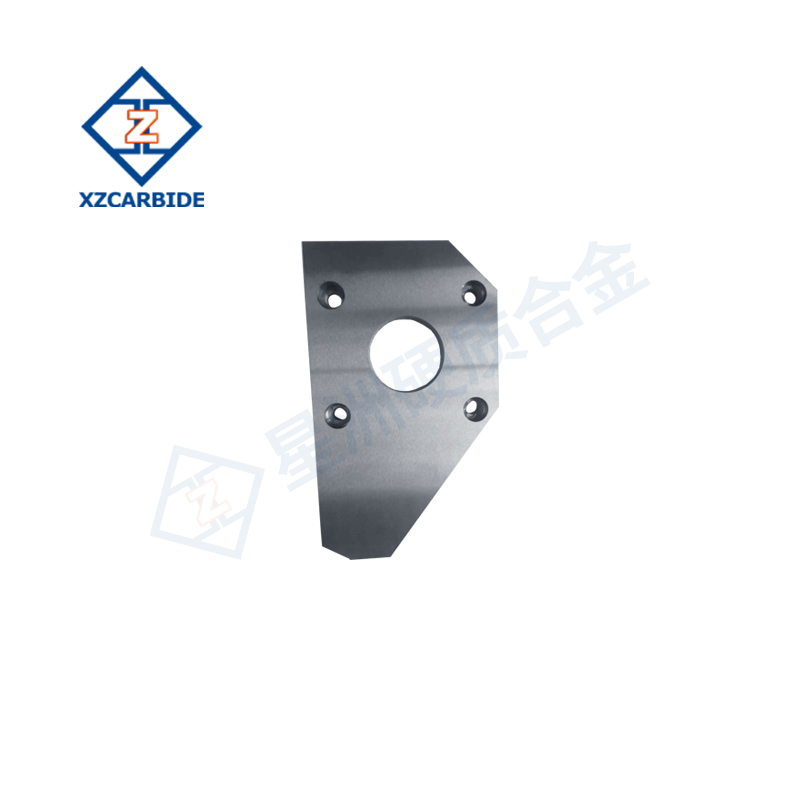

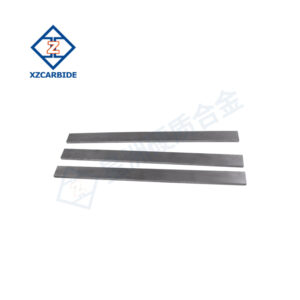

- Custom carbide plates in different shapes, sizes and material combinations to meet specific customer needs.

- Provide excellent hardness for high speed cutting and heavy duty working conditions.

- High wear resistance ensures stable cutting and machining performance over long periods of time.

- High-precision machining process guarantees consistent geometry and size of each plate.

- Suitable for tool making, mold making, mining equipment and chemical equipment and many other industry sectors.

- Stable performance in different complex machining environments, improving productivity and product quality.

Common Used Grades

Grade | International Standards | Density (g/cm3) | Hardness (HRA) | Bending Strength (MPa) | Scope of Application |

YG8 | K30 | 14.8 | 89.5 | ≥3500 | It has high strength, impact resistance and shock resistance, better than YG6. It is suitable for making forming knives and wear-resistant parts. |

YG11 | K40 | 14.4 | 88.5 | ≥3650 | Suitable for making stamping molds. |

NT15 | K40 | 14.0 | 87.5 | ≥3800 | Suitable for making stamping dies (processing silicon steel sheets), wear-resistant parts, etc. |

YG20 | K30 | 13.5 | 85.5 | ≥4200 | It has high strength. Suitable for making progressive dies and other stamping dies. |

YG6X | K10 | 14.9 | 91.5 | ≥3200 | It is a fine-grained alloy with good wear resistance and is suitable for making forming knives and wear-resistant parts. |

YL10.2 | K10 | 14.5 | 92 | ≥3850 | It is an ultra-fine grain alloy with high wear resistance, bending strength, anti-adhesion ability and pad strength. It is suitable for low-speed rough machining. |

Other grades are available on request

Avis

Il n’y a pas encore d’avis.