Main Features

- High-Precision Corner Radius Machining: Capable of high-precision rounding on workpiece edges or corners, it reduces stress concentration caused by sharp corners, thereby enhancing the workpiece’s lifespan.

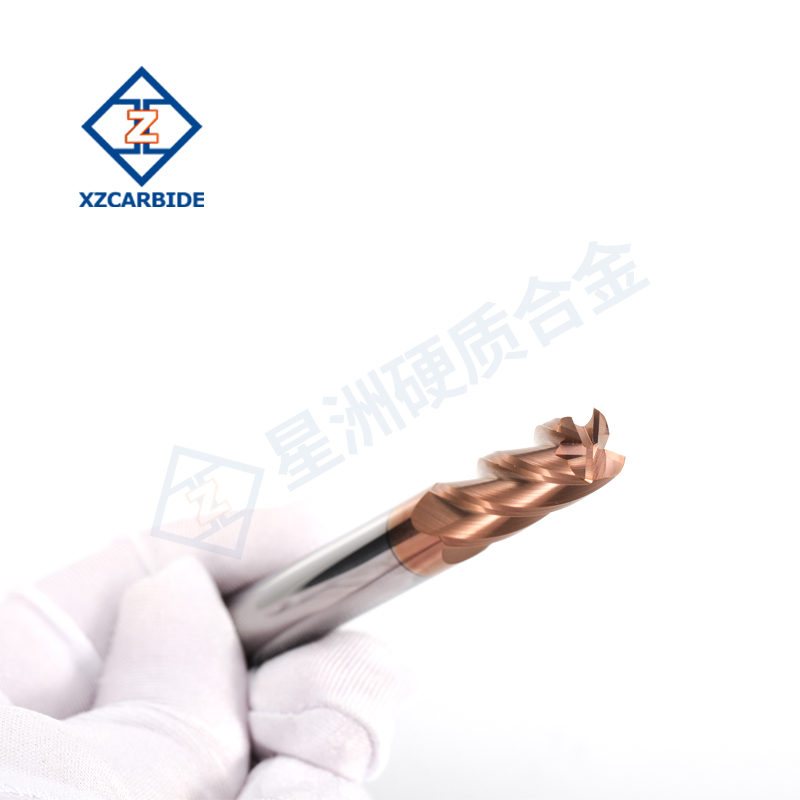

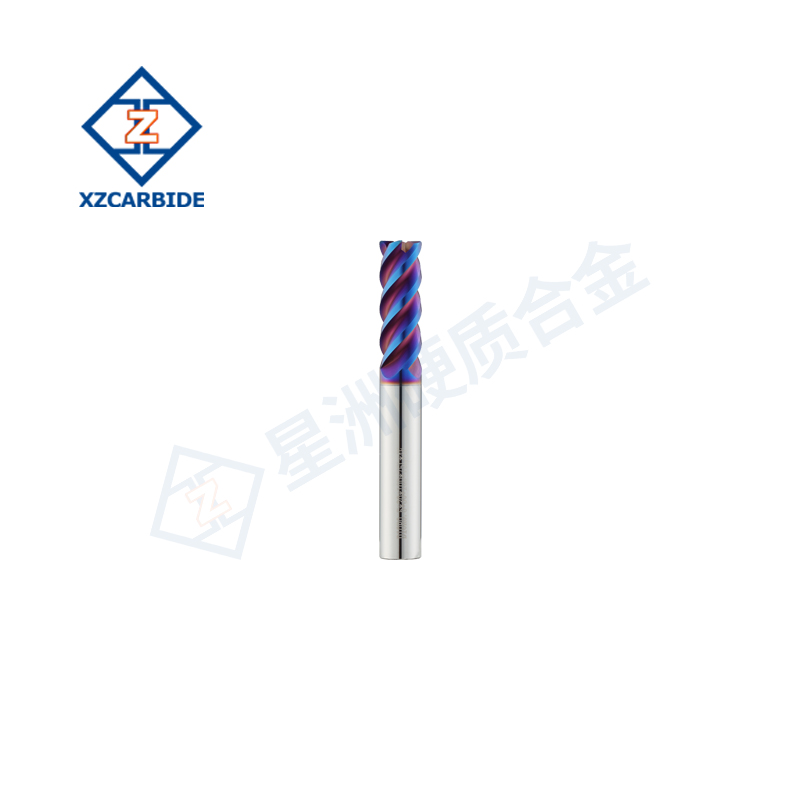

- Wear-Resistant Material: Made from high-performance carbide material, it offers exceptional wear resistance and heat resistance, extending the tool life.

- High Surface Finish: Ensures high surface quality on machined workpieces, reducing the need for subsequent processing and improving production efficiency.

- Various Specifications Available: Available in multiple corner radii and tool sizes to meet diverse machining needs.

- Wide Range of Applications: Suitable for machining various materials such as steel, stainless steel, aluminum alloys, and titanium alloys.

Product Specifications

| Matériel | Tungsten carbide |

| Corner Radius | 0.5mm, 1mm, 2mm, 3mm, etc. |

| Tool Diameter | 1-20 mm |

| Tool Length | 50-150 mm |

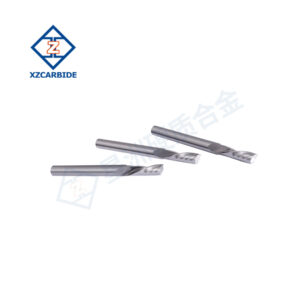

| Number of Flutes | 2 flutes,4 flutes |

| Coating | TiN, TiAlN, DLC, etc. are optional |

Technical Parameter

- Matériel: Usually use high-quality imported tungsten steel material, providing superior strength and wear resistance.

- Design: Includes non-equidistant design to reduce vibration and camber full groove design to improve chip removal performance.

- Advantages: High hardness, high efficiency, stability, sharpness and wear resistance.

Application Field

- Mold Manufacturing: Used to make mold fillet and chamfer, improve the accuracy and durability of the mold.

- Precision Machining: Suitable for mechanical parts requiring high-precision rounded corner machining.

Avis

Il n’y a pas encore d’avis.