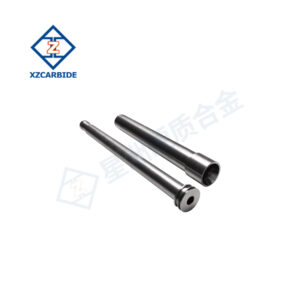

Advantages of Tungsten Carbide Nozzle

- Tungsten carbide nozzle has the quality of corrosion resistance, long service life, good performance and high cost performance.

- Bending strength reaches 2300N/mm and hardness reaches HRA90.

- Carbide nozzles are widely used in surface treatment, sandblasting, painting, sandblasting, cleaning, electronics, chemical process and other industries.

- Tungsten carbide materials: YG6, YG8, YG10, YG15, YG20, YG25, YWN6, YWN8.

- Sizes are available from 2mm to 400mm, original materials are available.

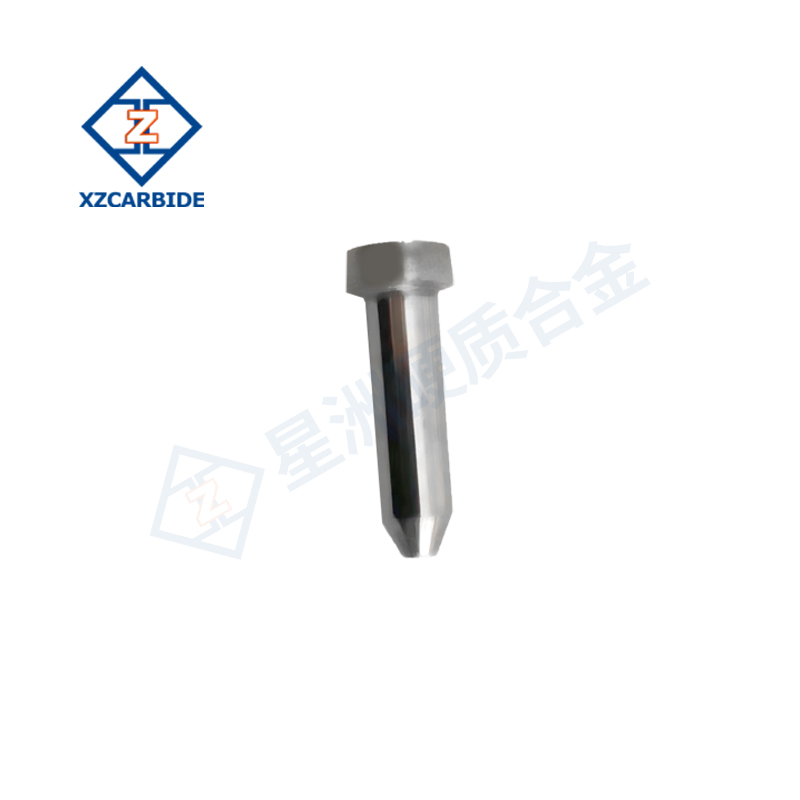

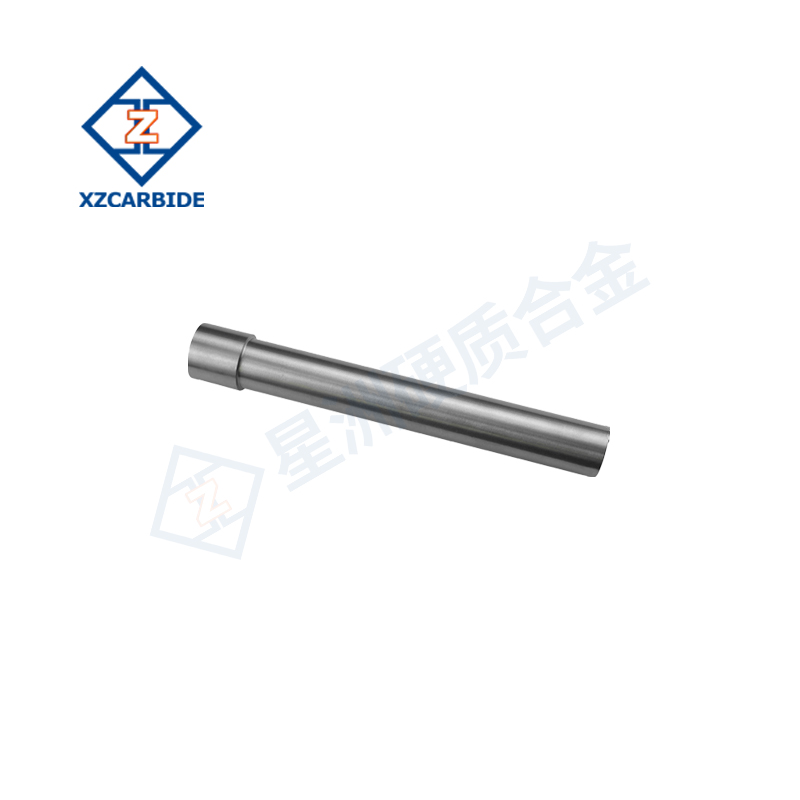

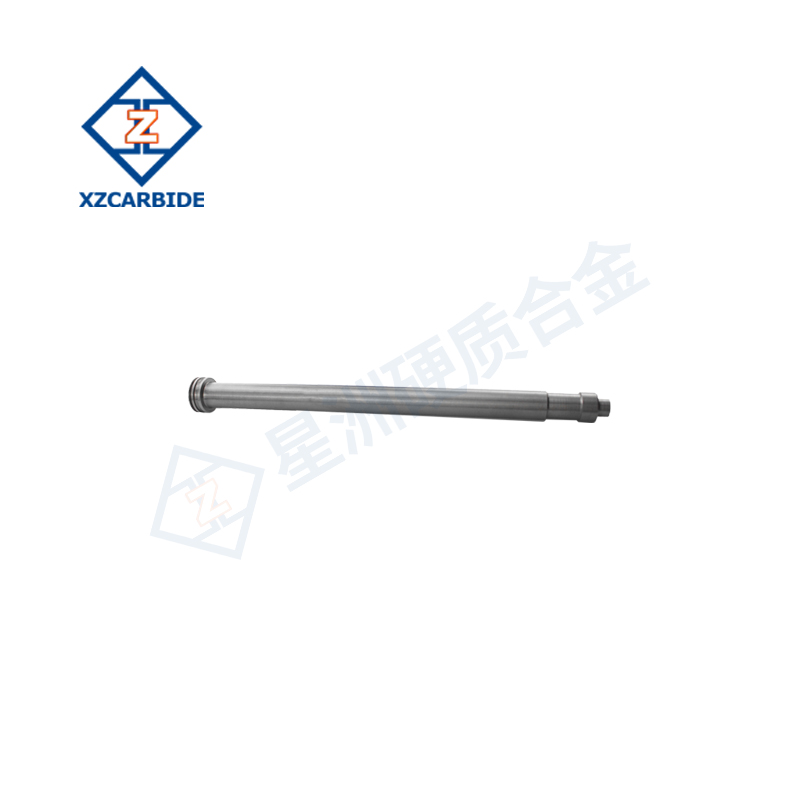

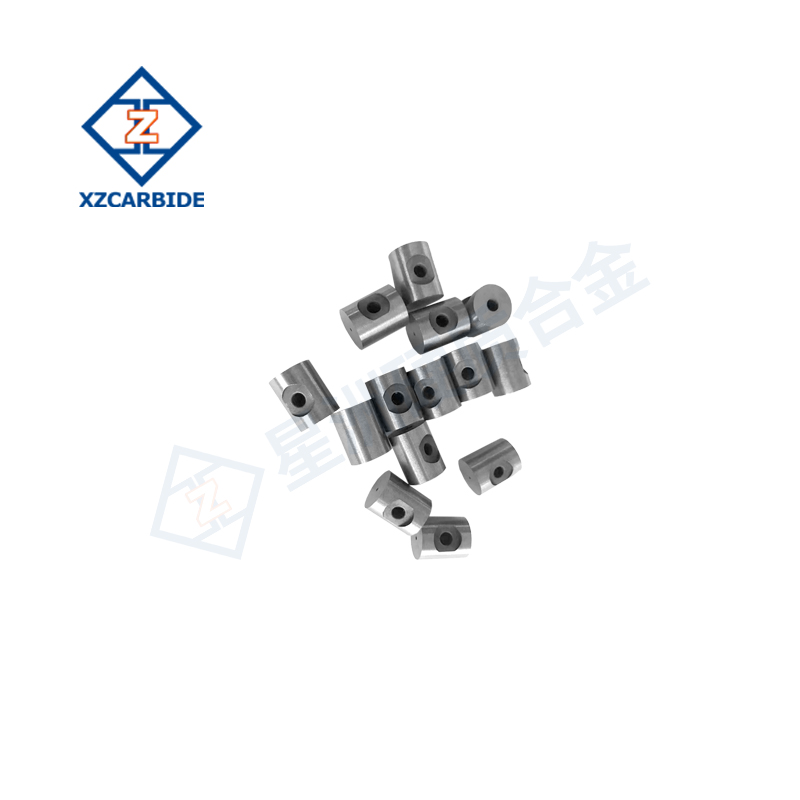

- Type: sandblasting nozzle, paint spraying nozzle, drill nozzle, long nozzle and various non-standard industrial nozzles.

- Customized according to drawings, with more than ten years of export experience and twenty years of manufacturing experience.

Production process

- Grinding

- Proportioning according to needs

- Wet grinding

- Drying

- Granulation

- Pressing

- Sintering

- Inspection

- Packaging

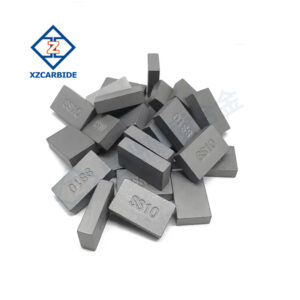

Main Products

- Cross thread nozzles

- Plum thread nozzles

- External hexagon thread nozzles

- Internal hexagon thread nozzles

- Y-type (three-slot) thread nozzles

- Gear drill nozzles

- Fracturing nozzles

Our Advantages

There are many sizes and types of products to choose from, and we can also provide products to customers according to their drawings and requirements. A variety of nozzles suitable for all drill bit designs, including threaded nozzles, standard nozzles and extended nozzles. Precise manufacturing to achieve nozzle position and arrangement, improved flow rate and reduced pressure loss. After several years of development, our products have been exported to the United States, Germany, Italy, Russia, South America and other countries. The products are of excellent quality and competitive price. Our hard work attitude and responsiveness have been recognized by customers. We hope to establish new business relationships with new customers.

Performance of Cemented Carbide Products

| Model | Binder (Wt%) | Density(g/cm³) | Hardness (HRA) | TRS ( 2N/mm2) |

| YG6 | 6 | 14.8 | 90 | 1520 |

| YG6X | 6 | 14.9 | 91 | 1450 |

| YG8 | 8 | 14.7 | 89.5 | 1750 |

| NT15 | 15 | 14 | 87 | 2050 |

| YG20 | 20 | 13.5 | 85.5 | 2450 |

| YG25 | 25 | 12.1 | 84 | 2550 |

Avis

Il n’y a pas encore d’avis.