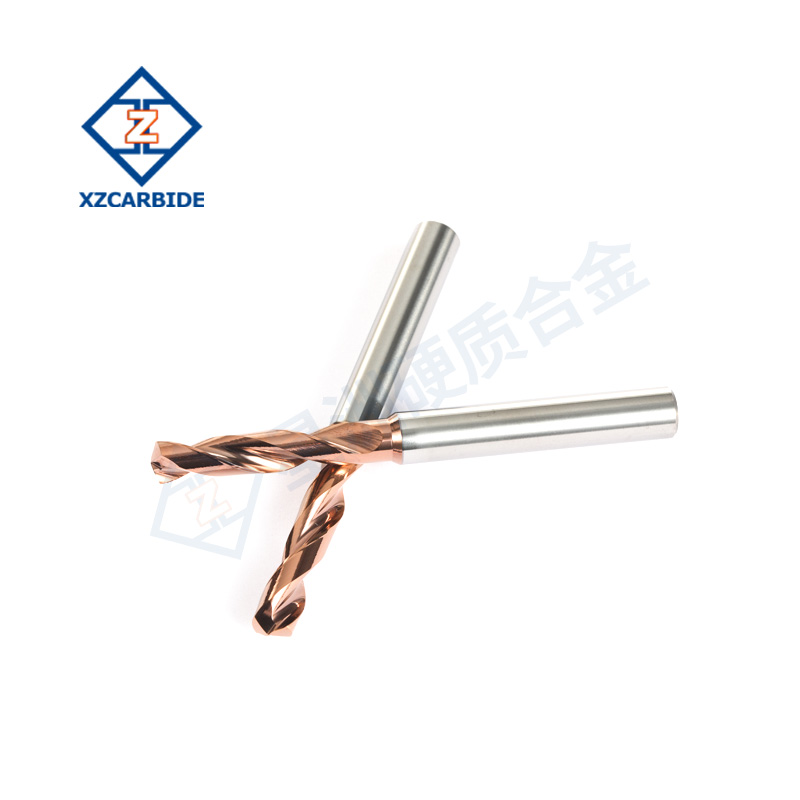

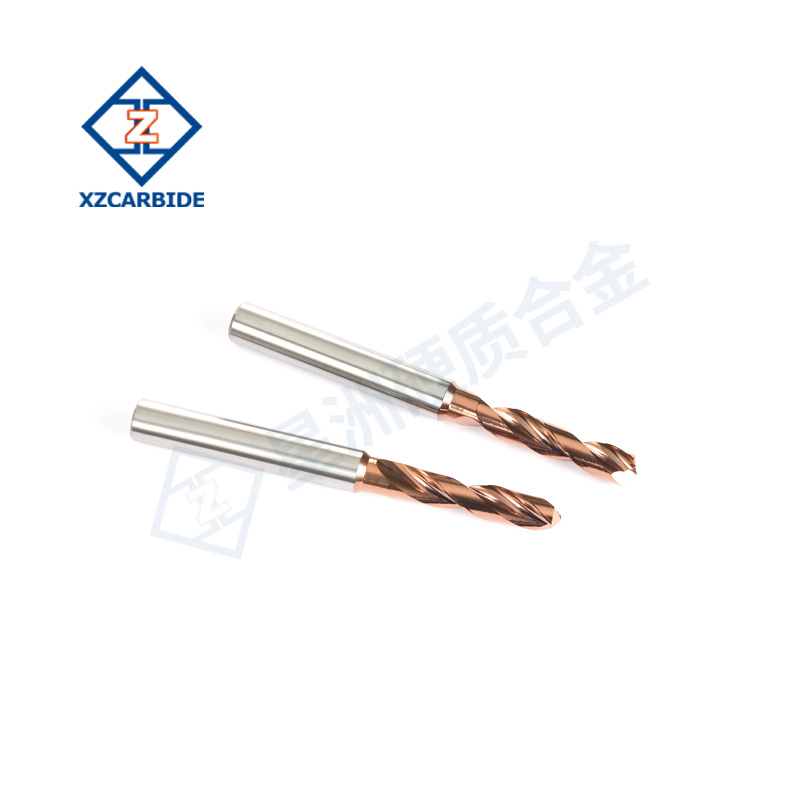

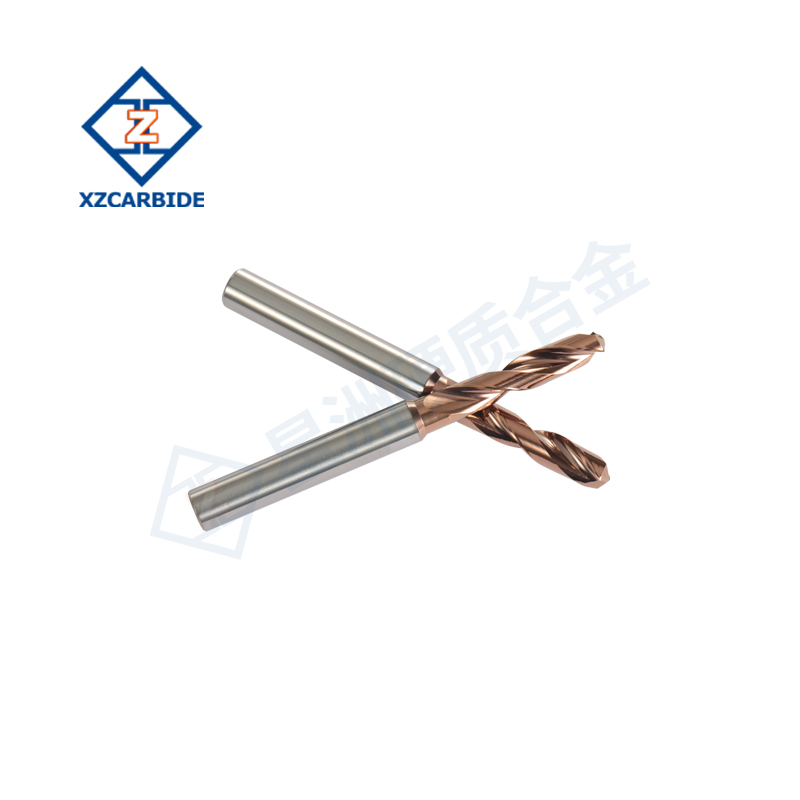

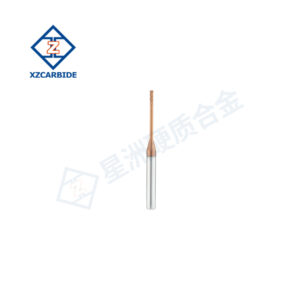

With its precise design and efficient chip removal capabilities, it ensures stability and machining accuracy at high speeds. This tool is widely used in industries such as aerospace, automotive manufacturing, mold making, and mechanical engineering.

Products Features

- High hardness: Crafted from top-grade carbide material, ensuring superior hardness for extended tool life.

- Exceptional wear resistance: Designed to withstand high levels of wear, making it ideal for intensive drilling tasks.

- Precision rngineering: Manufactured with tight tolerances for precise drilling operations and accurate hole dimensions.

- Efficient chip evacuation: Optimized flute design facilitates smooth and efficient chip removal, reducing heat buildup.

- Versatility: Suitable for drilling a wide range of metals, including steel, stainless steel, cast iron, and non-ferrous metals.

- High speed performance: Capable of maintaining performance and accuracy at high drilling speeds.

- Durable construction: Robust build quality ensures reliable performance in demanding industrial environments.

- Wide application range: Perfect for use in aerospace, automotive, mold making, and general mechanical industries.

- Corrosion resistance: Enhanced resistance to corrosion, extending the tool’s operational life in challenging conditions.

- Advanced coatings: Available with advanced coatings to further enhance tool life and performance in specific applications.

Common Used Grades

| Grade | Composition | Density (g/cm3) | Hardness (HRA) | Flexural Strength (MPa) | Properties |

| YG6 | 94% WC, 6% Co | 14.6 | 89 | 1520 | High hardness and good wear resistance , suitable for general wear and impact applications. |

| YG8 | 92% WC, 8% Co | 14.5 | 88.5 | 1600 | High hardness with impact resistance , suitable for medium impact and wear conditions. |

| YG15 | 85% WC, 15% Co | 14.0 | 86 | 2400 | High flexural strength and impact toughness , ideal for high impact and wear environments. |

| YNi8 | 92% WC, 8% Ni | 14.7 | 88.5 | 1500 | Good corrosion resistance and toughness , suitable for chemical and corrosive media environments. |

| YG20 | 80% WC, 20% Co | 14.0 | 84 | 2800 | Extremely high flexural strength and toughness , ideal for high impact and high wear environments. |

Avis

Il n’y a pas encore d’avis.