Basic Information

|

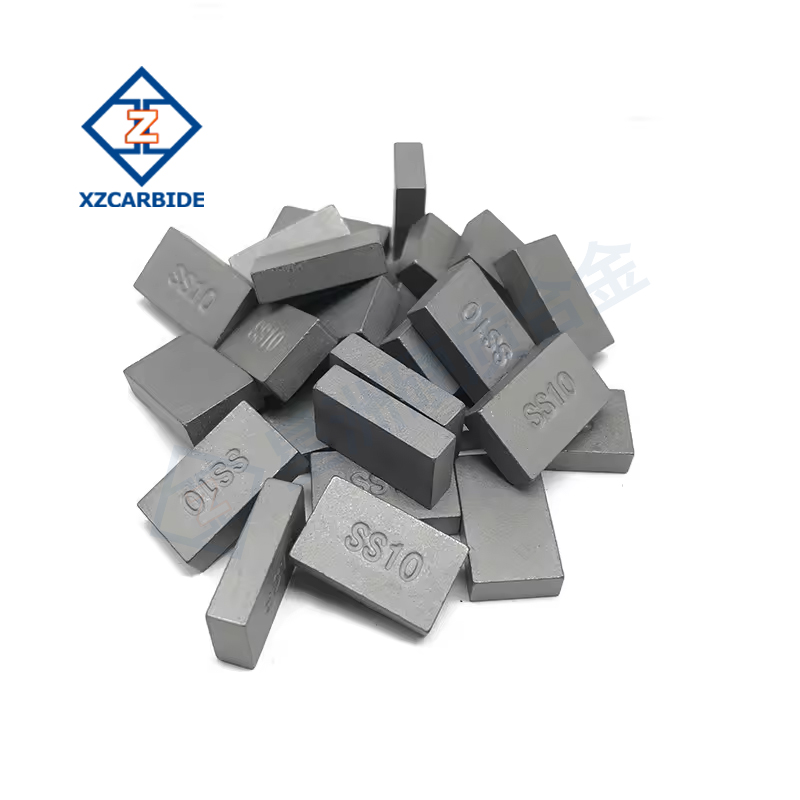

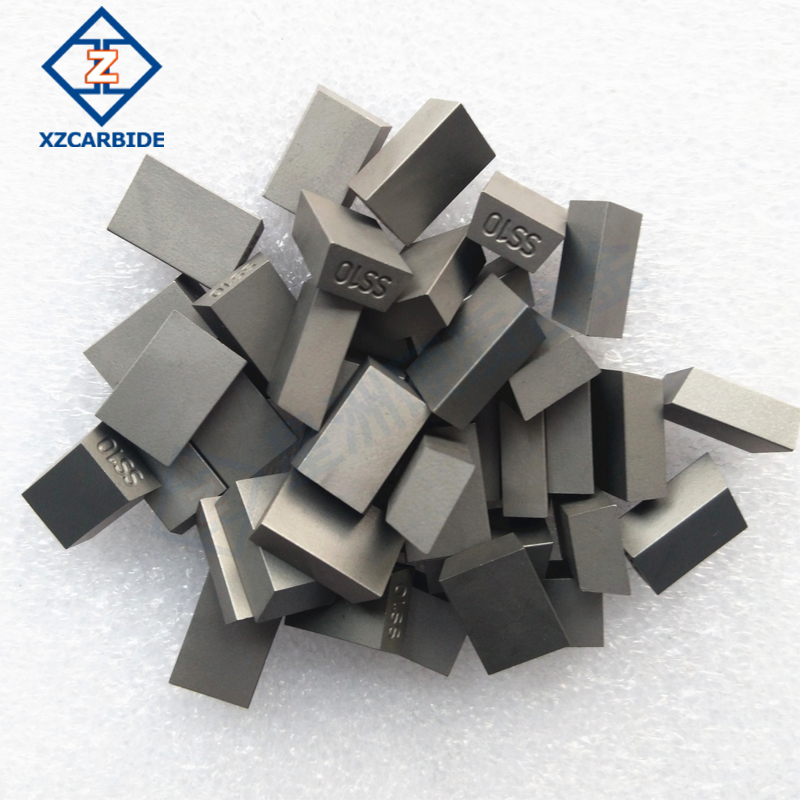

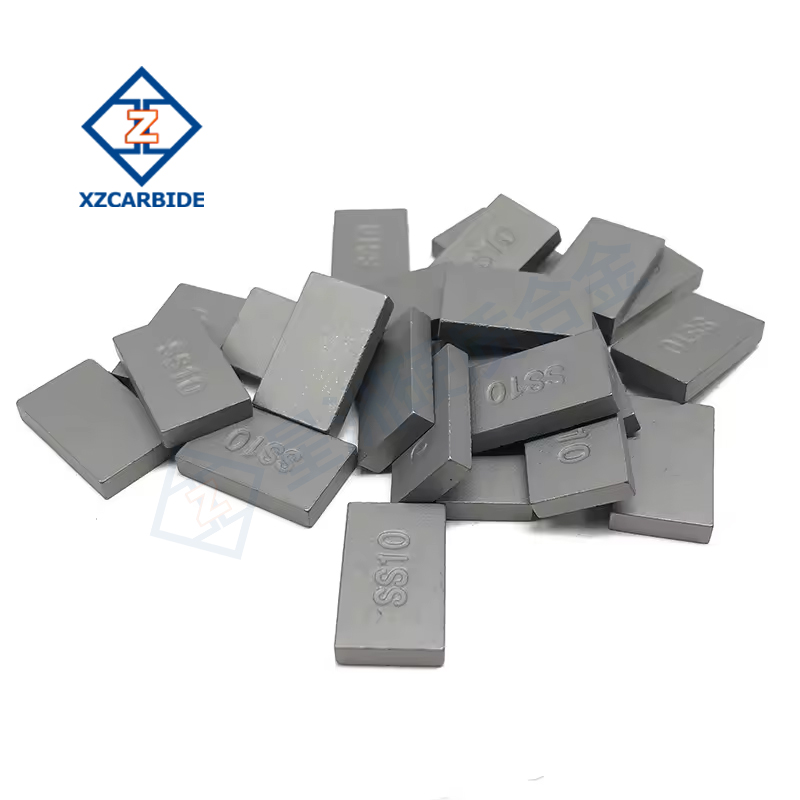

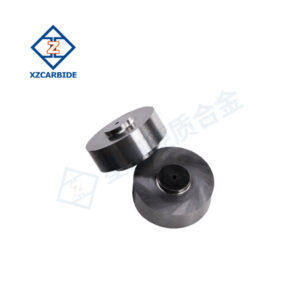

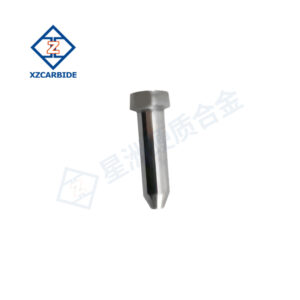

Matériel |

100% raw cemented carbide |

|

Grade |

Multiple grades available on request |

|

Specification |

Length*Width*Thickness, exact specifications are strictly followed by drawings |

Main Features and Advantages

- Excellent hardness and wear resistance: Tungsten carbide material ensures the long-term use of brazed tips under high load and high speed cutting conditions.

- Stable high-temperature performance: The ability to maintain stable cutting performance in high-temperature environments extends tool life and improves productivity.

- Precise geometry and dimensions: High-precision manufacturing process ensures that each brazed tip has consistent geometry and dimensions, ensuring accuracy and stability of work-piece machining.

- Customization options: Based on customer-specific requirements, brazed tips can be customized with different shapes, sizes and cutting characteristics to meet the needs of different machining tasks.

Applications

Widely used in the machining of metal, wood, stone and construction materials.

Common Used Grade

|

Grade |

ISO

Code |

Density

g/cm3 |

Hardness

HRA |

T.R.S

MPa |

Applications Recommended |

|

YG3 |

K05 | 15.10 | 92.0 |

1400 |

Suitable for finishing of cast iron and nonferrous metal. |

|

YG6X |

K10 | 14.95 | 91.5 |

1800 |

The finishing & semi-finishing of cast iron and nonferrous metals and also for the machining of manganese steel and hardening steel. |

|

YG6 |

K15 | 14.95 | 90.5 |

1900 |

Suitable for the roughing of cast iron and light alloys and also for the milling of cast iron and low-alloy steel. |

|

YG8 |

K20 | 14.80 | 89.5 |

2200 |

|

|

YW1 |

M10 | 13.10 | 91.6 |

1600 |

Suitable for finishing and semi-finishing of stainless steel and conventional alloy steel. |

|

YW2 |

M20 | 13.00 | 90.6 |

1800 |

The grade can be used for the semi- finishing of stainless steel and low-alloy steel and it is mainly used for the machining of railway wheel hubs. |

|

YT15 |

P10 | 11.4 | 91.5 |

1600 |

Suitable for the finishing and semi- finishing for steel and cast steel with a moderate feed rate and rather high cutting speed. |

|

YT14 |

P20 | 11.6 | 90.8 |

1700 |

Suitable for the finishing and semi-finishing of steel and cast steel. |

|

YT5 |

P30 | 12.9 | 90.5 |

2200 |

Suitable for the heavy duty rough turning of and cast steel with a big feed rate at a medium and low speed under unfavorable working conditions. |

Avis

Il n’y a pas encore d’avis.