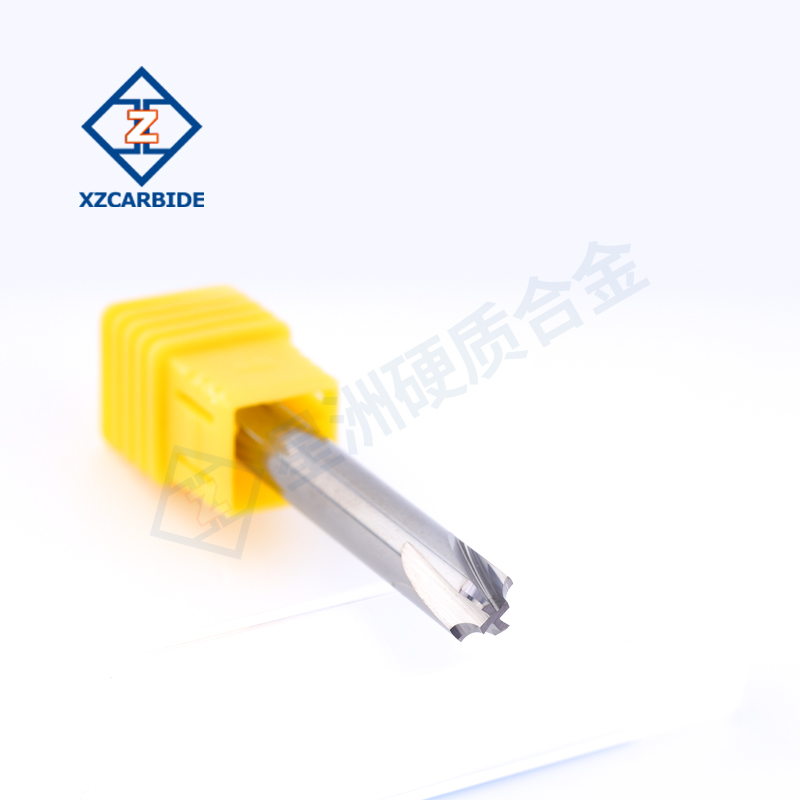

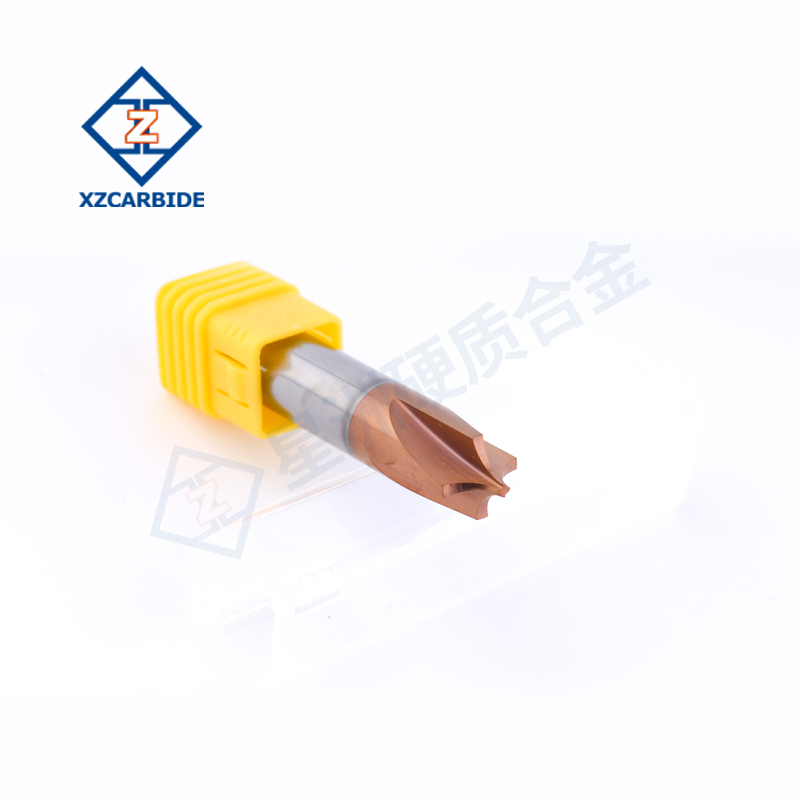

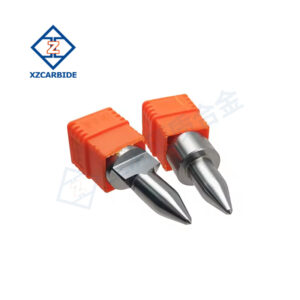

Product Features

- Precise machining: The special cutting edge design can accurately machine the required fillet radius to ensure machining accuracy.

- Efficient cutting: Optimized number of teeth and helix angle design improves cutting efficiency and reduces machining time.

- Strong durability: Selection of high-quality materials and precision machining to ensure tool durability and reduce the number of tool changes.

- Widely used: Suitable for machining different kinds of materials, including metals, plastics, composites, etc. Widely used in molds, aerospace, automotive manufacturing and other fields.

Product Information

| Diameter | Φ6mm, Φ8mm, Φ10mm and more |

| Fillet Radius | R0.5, R1, R2 and more |

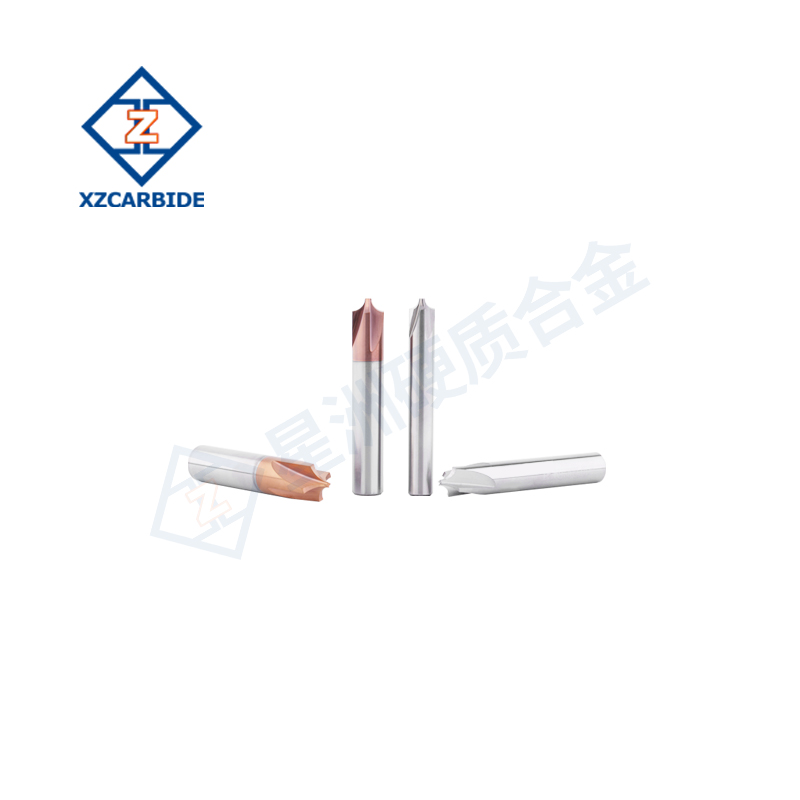

| Number of Blades | Usually 2 or 4 blades |

| Helix Angle | Designed based on cutting needs, affecting chip removal and cutting forces. |

| Coating | Available with uncoated, TiAlN coatings, and other options to improve tool performance and life. |

Product Parameters

| Fillet Radius | Blade Diameter | Blade Length | Shank Diameter | Overall Length | Number of Blades |

| R0.5 | 4 | 3 | 4 | 50 | 2/4 |

| R1.0 | 4 | 2 | 4 | 50 | 2/4 |

| R1.5 | 6 | 3 | 6 | 50 | 2/4 |

| R2.0 | 6 | 2 | 6 | 50 | 2/4 |

| R2.5 | 8 | 3 | 8 | 50 | 2/4 |

| R3.0 | 8 | 2 | 8 | 60 | 2/4 |

| R4.0 | 10 | 2 | 10 | 60 | 2/4 |

| R5.0 | 12 | 2 | 12 | 75 | 2/4 |

| R6.0 | 14 | 2 | 14 | 75 | 2/4 |

Áreas de aplicación

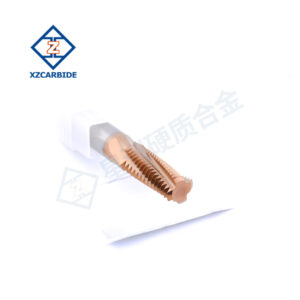

- Graphite machining: Particularly suitable for efficient machining of graphite, providing long life and high cutting performance.

- Mold manufacturing: Used for internal hole machining of high-precision molds.

- Machining: For internal milling and contouring of mechanical parts.

Valoraciones

No hay valoraciones aún.