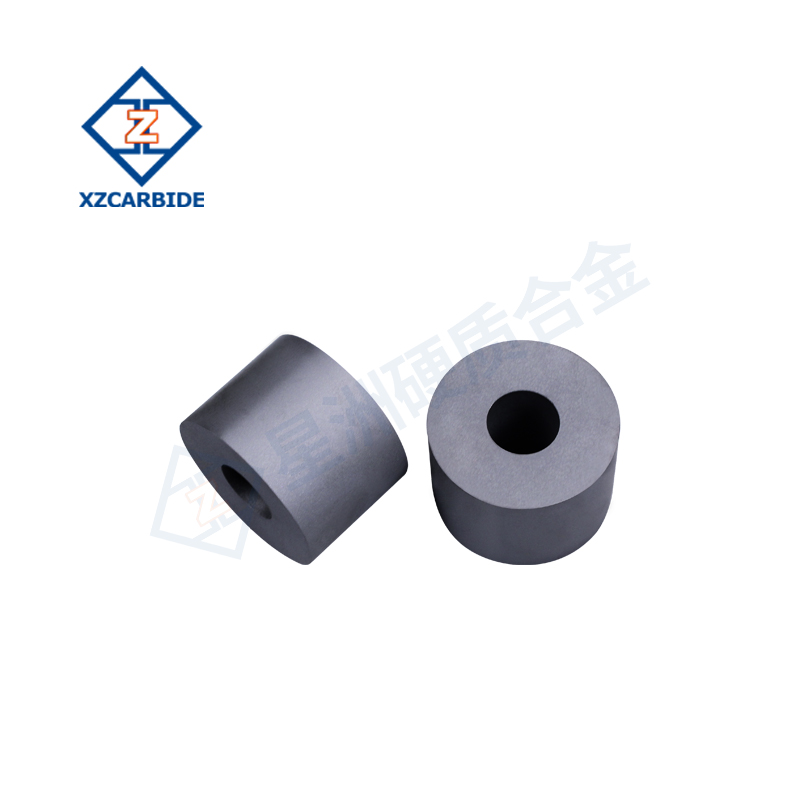

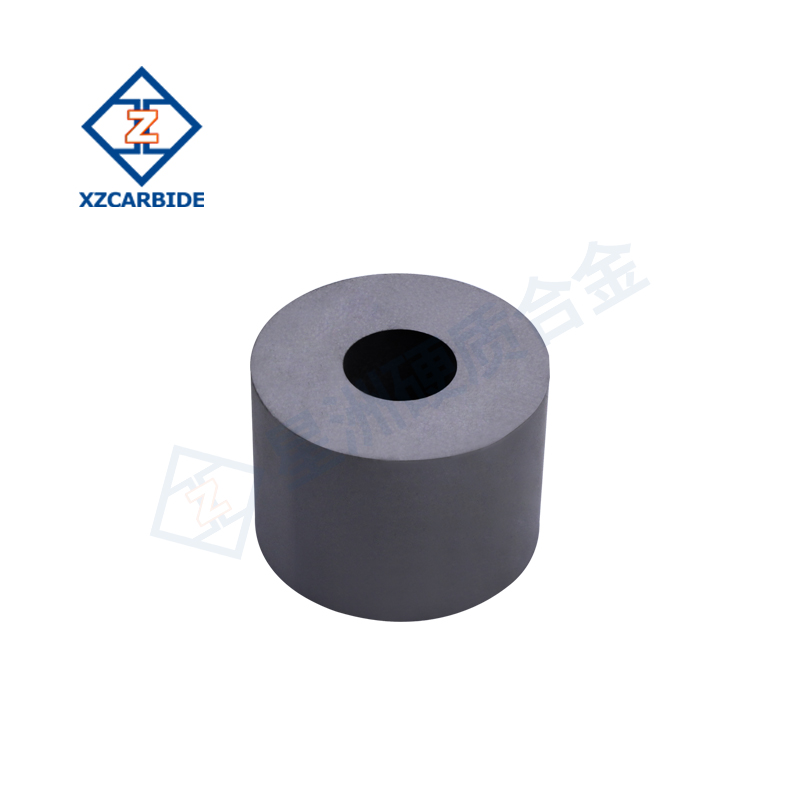

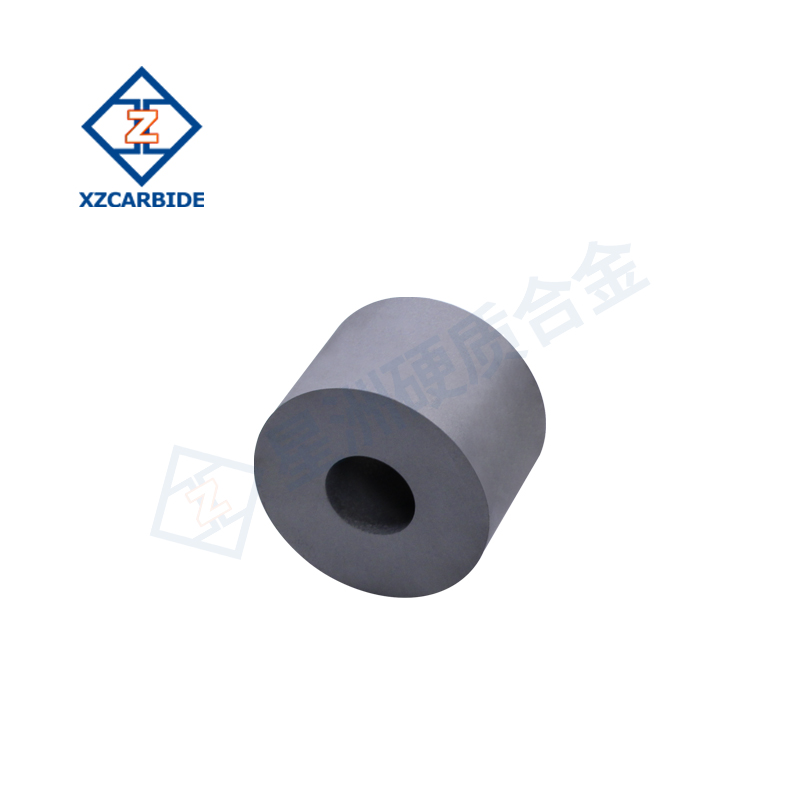

Descripción del Producto

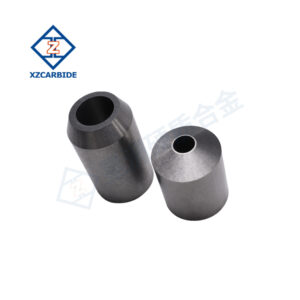

Carbide cold forging dies are made of high quality tungsten-cobalt alloy with extremely high hardness and abrasion resistance, suitable for high strength cold forging processing. Its excellent impact resistance and precision manufacturing process ensure high accuracy and consistency of the dies, which are widely used in automotive, aerospace, machinery manufacturing and electronics industries.

Product Características

1. Use 100% tungsten carbide pure raw material.

2. High impact strength.

3. Durable with long life time.

4. Many grades available for your choice.

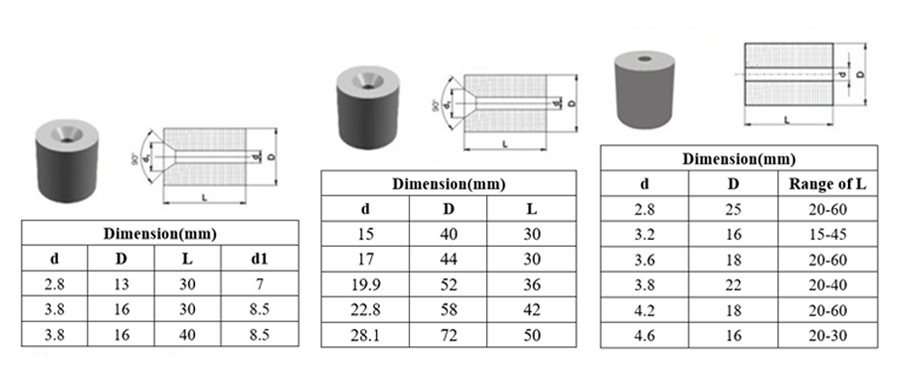

Product Parameters

Basic Dimension

We support customization as well.

Common Used Grades

| Calificación | Composition | Densidad (g/cm3) | Dureza (HRA) | Flexural Strength (MPa) | Properties |

| YG6 | 94% WC, 6% Co | 14.6 | 89 | 1520 | High hardness and good wear resistance , suitable for general wear and impact applications. |

| YG8 | 92% WC, 8% Co | 14.5 | 88.5 | 1600 | High hardness with impact resistance , suitable for medium impact and wear conditions. |

| YG15 | 85% WC, 15% Co | 14.0 | 86 | 2400 | High flexural strength and impact toughness , ideal for high impact and wear environments. |

| YNi8 | 92% WC, 8% Ni | 14.7 | 88.5 | 1500 | Good corrosion resistance and toughness , suitable for chemical and corrosive media environments. |

| YG20 | 80% WC, 20% Co | 14.0 | 84 | 2800 | Extremely high flexural strength and toughness , ideal for high impact and high wear environments. |

Application Of Cold Heading And Cold Punching Dies

Suitable for cold heading and cold punching standard parts, screws and rivets of copper, aluminum, steel and alloy steel.

Valoraciones

No hay valoraciones aún.