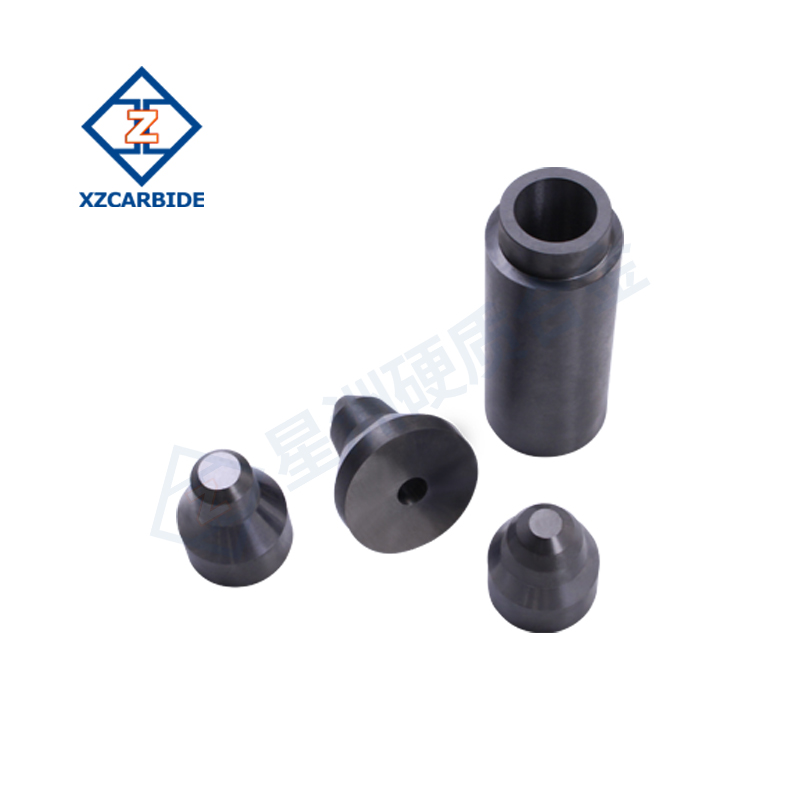

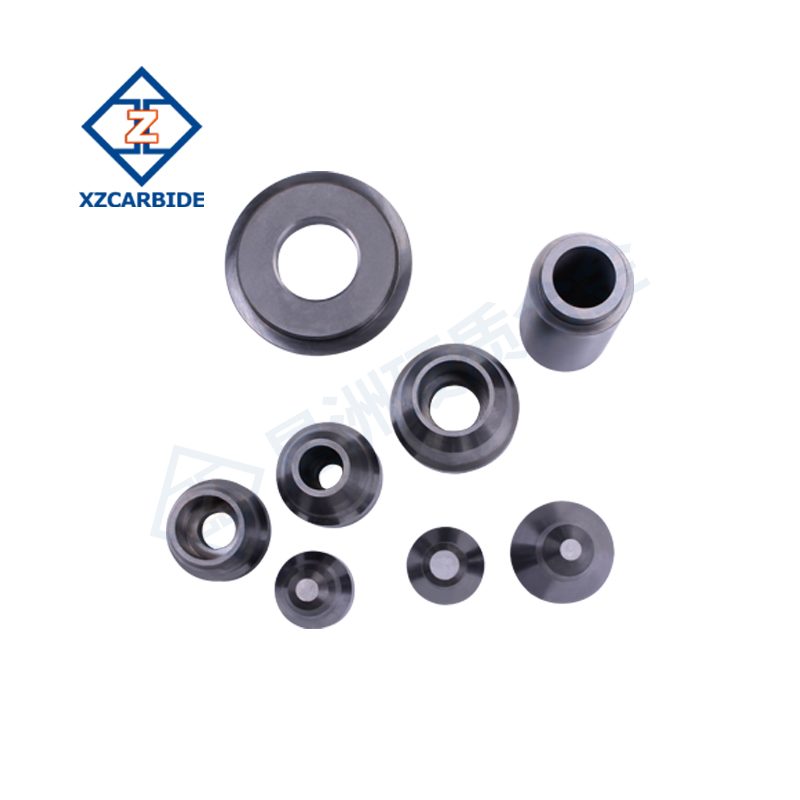

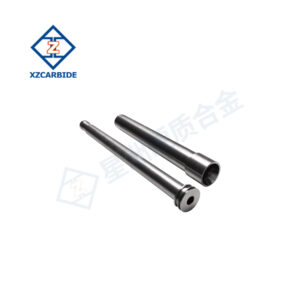

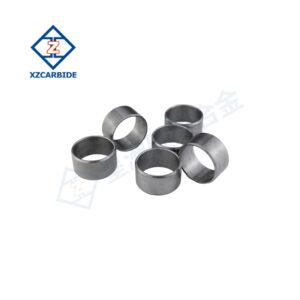

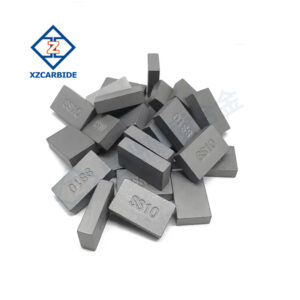

Product Description

- High hardness: Carbide valve seat has high hardness, usually the hardness value can reach HRA85 or above, which can effectively resist medium scouring and particle abrasion.

- Abrasion resistance: Excellent abrasion resistance makes the valve seat maintain stable sealing effect during long time use, reducing maintenance and replacement times.

- Corrosion resistance: Good resistance to diverse corrosive media, prolonging the service life of the valve seat.

- High temperature resistance: Can maintain stable physical and chemical properties in high temperature environment, adapt to a variety of complex working conditions.

- High precision: Manufactured through precision machining technology to ensure the sealing accuracy between the valve seat and spool, improving the overall performance of the valve.

- Customized service: Provide customized service according to customers’ needs, including special size, shape and material of carbide valve seat.

Grade Parameters

| Grade | WC+ | CO+ | Hardness HRA | Density g/m3 | T.R.S MPa |

| YG6 | 94% | 6% | 91 | 14.6~15.0 | 1700 |

| YG6X | 94% | 6% | 92 | 14.6~15.0 | 1450 |

| YG8 | 92% | 8% | 89 | 14.4~14.8 | 1800 |

Application Areas

- Oil extraction: Control fluid flow in oil wells.

- Natural gas processing: To regulate the flow of fluids in natural gas transportation and processing systems.

- Chemical industry: Used for valve sealing in chemical processing and material transportation.

Precautions

- Selection and matching: When purchasing carbide valve seats, it is necessary to select the appropriate models and specifications according to the specific application scenarios and needs to ensure the matching with the valve system.

- Installation specification: In the installation process, it is necessary to follow the relevant norms and standards to ensure the correct installation and sealing effect of the valve seat.

- Use environment: Avoid using the carbide valve seat in the working environment beyond its performance range, so as not to cause damage or affect the service life.

Bewertungen

Es gibt noch keine Bewertungen.