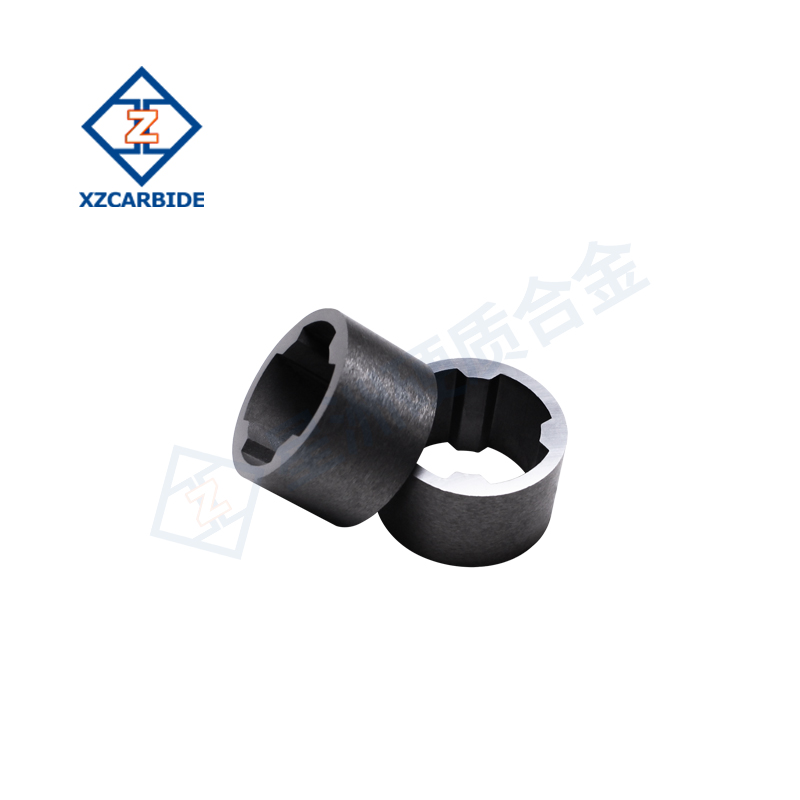

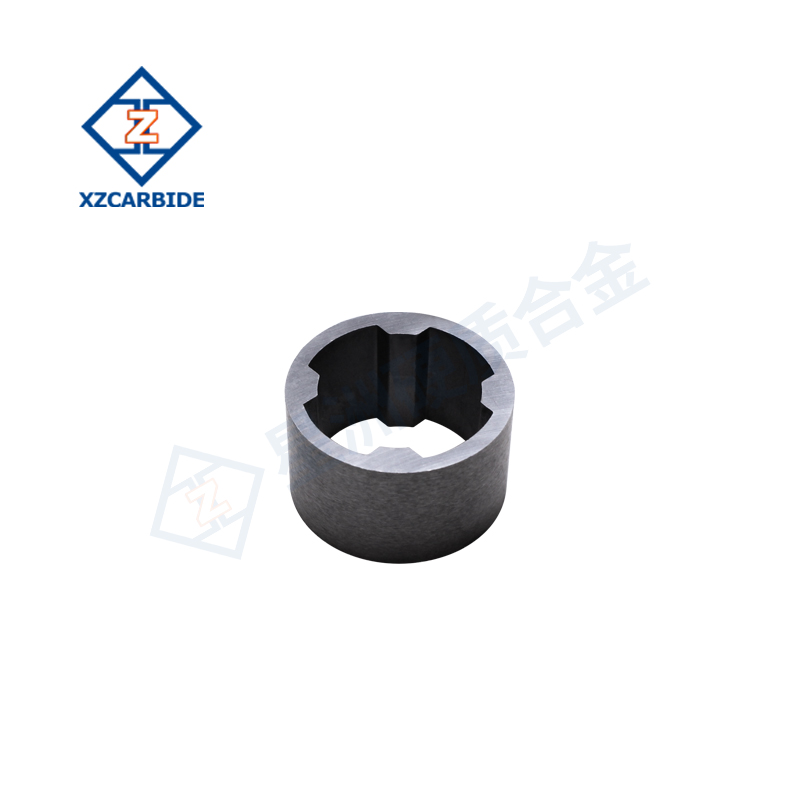

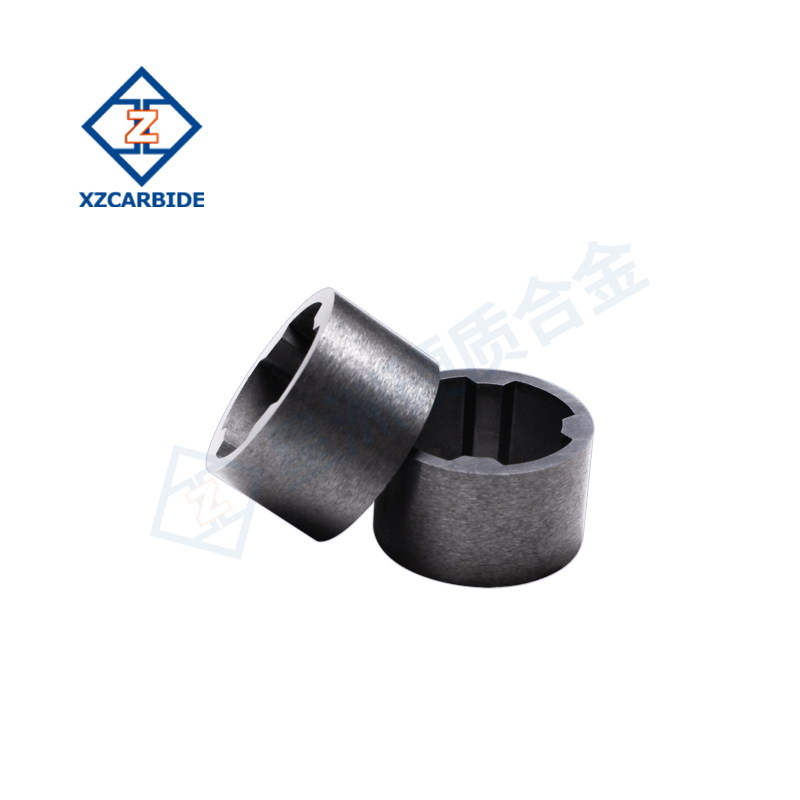

Technical Parameters

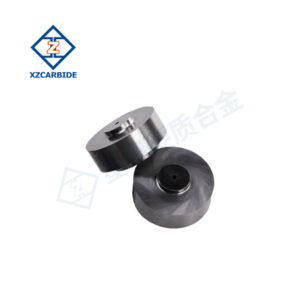

| Material | High quality tungsten carbide |

| Hardness | Depending on the specific material and technique, generally up to HRA 85° or more |

| Size | Inside dia. x outside dia. x length, customized sizes available to meet different needs |

| Working Temperature | -50°C~500°C |

| Working Pressure | Depending on equipment specifications and design requirements |

| Accuracy | High-precision machining to meet various precision fit requirements |

Product Features

- Excellent abrasion resistance: The high hardness of cemented carbide makes the bushing sleeve maintain excellent abrasion resistance when it is subjected to high loads and high-speed friction, which greatly extends the service life of the equipment.

- High-temperature resistance: Even in a high-temperature environment, the cemented carbide bushing sleeve can maintain stable physical and chemical properties, and will not fail due to thermal expansion or thermal stress, which ensures the normal operation of the equipment under high-temperature working conditions.

- High-precision processing: Advanced processing technology and equipment are adopted to ensure the dimensional accuracy and surface finish of the bushing sleeve, which improves the matching accuracy with shafts, rods and other components and reduces friction and wear.

- Good corrosion resistance: Cemented carbide material has good corrosion resistance to many kinds of chemical media, which can maintain stable performance in corrosive environments and is suitable for many kinds of complex working conditions.

- Widely used: Widely used in petroleum, chemical industry, metallurgy, automobile manufacturing and other fields, especially in occasions requiring high wear resistance, high corrosion resistance and high temperature stability, such as oil pumps, valves, bearings and other components of the bushing protection.

Applications

- Machinery manufacturing

- Automobile industry

- Chemical equipment

- Aerospace

Bewertungen

Es gibt noch keine Bewertungen.