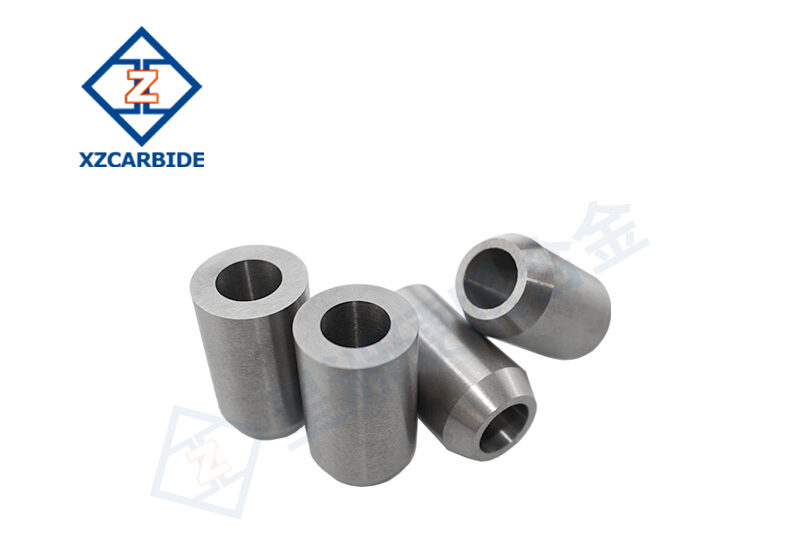

Carbide punching dies are vital precision tools used in metalworking, particularly in metal stamping processes. They are essential for creating precise holes, shapes, and profiles in various metals and are widely utilized in industries such as automotive, electronics, and aerospace. This article explores the properties, design, manufacturing, applications, advantages, challenges, and future trends of carbide punching dies in detail.

Properties of Carbide Materials

Carbide materials, typically composed of tungsten carbide and cobalt binder, exhibit the following notable properties:

- Hardness: Carbide materials possess exceptional hardness, significantly surpassing traditional die materials such as hardened steel. This high hardness allows carbide dies to maintain their shape and cutting edge over extended periods of use.

- Wear Resistance: Carbide punching dies offer outstanding wear resistance, making them ideal for high-frequency and high-volume production environments. Their ability to resist wear and abrasion extends the lifespan of the dies and reduces the frequency of replacements.

- Toughness: Despite their high hardness, carbide materials retain sufficient toughness to withstand the impact and mechanical stresses encountered during punching operations. This combination of hardness and toughness ensures the durability and reliability of carbide dies.

Design and Construction of Carbide Punching Dies

Design Considerations

- Part Geometry: The complexity of the part geometry influences the design of the punching die. The die must be meticulously designed to accommodate intricate shapes and ensure precise cuts and punches.

- Material Thickness: The thickness of the material being processed directly impacts the design of the punching die. Thicker materials require higher punching forces and more robust die structures to achieve clean and accurate results.

- Production Volume: High-volume production demands dies that offer longevity and consistent performance. The design should focus on durability and efficiency to maximize productivity and minimize downtime.

Manufacturing Process

- Precision Machining: The manufacturing of carbide punching dies involves precision machining using advanced equipment such as CNC machines and electrical discharge machining (EDM). These technologies ensure the dies meet exact specifications and maintain tight tolerances.

- Heat Treatment: To enhance the hardness and toughness of the carbide dies, they undergo heat treatment processes. This step is crucial to ensure the dies can withstand the high stresses and temperatures encountered during punching operations.

- Assembly: The final assembly of the die components requires precise alignment and fitting. Each component, including punches, dies, strippers, and guides, must be meticulously assembled to ensure optimal performance and accuracy during use.

Applications of Carbide Punching Dies

Carbide punching dies find extensive applications across various industries:

- Automotive Industry: Used for creating precise holes and shapes in automotive components such as brackets, panels, and chassis parts. The high precision and durability of carbide dies ensure the production of high-quality automotive parts.

- Electronics Manufacturing: Employed in the production of circuit boards, connectors, and electronic enclosures. Carbide dies provide accurate and clean cutouts and openings, enhancing the reliability and functionality of electronic devices.

- Aerospace and Aviation: Critical for manufacturing complex and precise parts for aircraft and spacecraft. The high tolerances and durability of carbide dies meet the stringent requirements of the aerospace industry.

Advantages of Carbide Punching Dies

The advantages of using carbide punching dies are substantial:

- Superior Hardness and Wear Resistance: The exceptional hardness and wear resistance of carbide materials result in extended tool life and reduced downtime for maintenance and replacements.

- High Precision and Accuracy: Carbide dies deliver consistent performance, ensuring that each part produced meets stringent quality standards and tight tolerances.

- Versatility: Carbide punching dies are capable of processing a wide range of metals, including steel, aluminum, copper, and titanium alloys. This versatility makes them suitable for diverse applications and industries.

Challenges and Considerations

While carbide punching dies offer numerous benefits, they also present certain challenges and considerations:

- Initial Cost: The manufacturing and initial investment costs of carbide dies are higher compared to traditional dies. However, the long-term benefits, including reduced maintenance and replacement costs, often outweigh the initial expenses.

- Maintenance: Regular maintenance practices are essential to ensure the optimal performance and longevity of carbide dies. This includes routine cleaning, lubrication, and periodic regrinding to maintain the sharpness and precision of the dies.

Future Trends in Carbide Punching Die Technology

The future of carbide punching dies is marked by ongoing innovation and advancements:

- New Carbide Grades: Continued research and development are leading to the creation of new carbide grades with enhanced properties tailored for specific applications. These advancements aim to further improve the performance and durability of carbide dies.

- Automation and Digitalization: The integration of Industry 4.0 technologies, such as automation, data analytics, and digital twin technology, is transforming the die manufacturing process. These innovations enhance production efficiency, quality control, and lead times.

- Sustainability Initiatives: Manufacturers are increasingly focusing on sustainable practices in carbide die production. This includes the use of eco-friendly materials, recycling programs, and processes that reduce the environmental impact.

Conclusion

Carbide punching dies are indispensable tools in modern manufacturing, offering unparalleled precision, durability, and versatility. Their superior properties make them ideal for high-volume and high-precision applications across various industries. As technology continues to advance, carbide die manufacturers are poised to innovate further, driving improvements in performance, cost-efficiency, and sustainability. These developments ensure that carbide punching dies will remain at the forefront of metalworking technology, meeting the evolving demands of the industry.