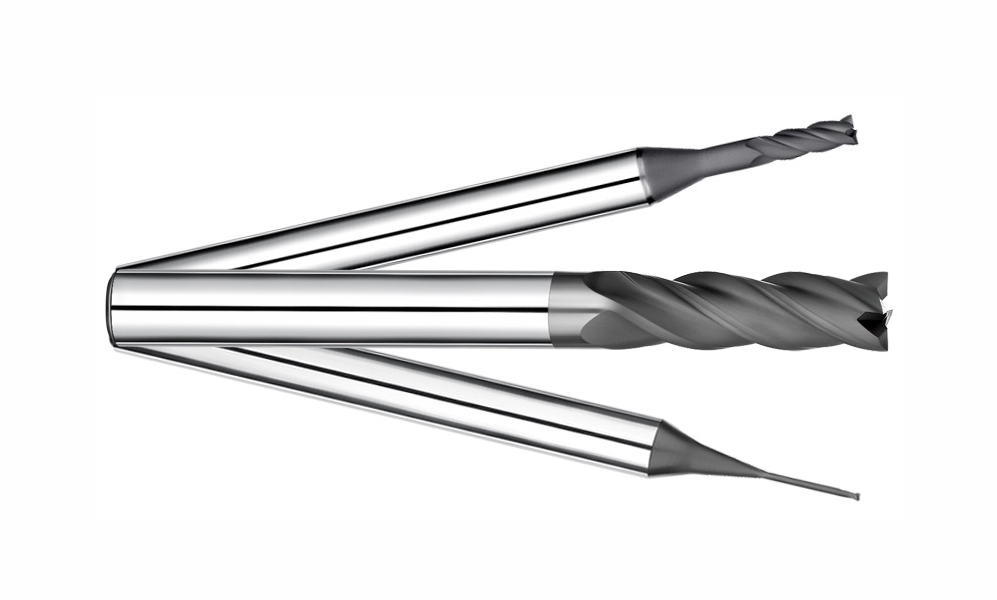

Carbide long neck end mills hold an important position in modern manufacturing due to their unique design and superior performance. They excel in deep cavity machining, complex surface processing, and high-precision tasks, making them indispensable tools across various industries. This article explores the detailed applications, advantages, and significance of carbide long neck end mills in different fields.

Deep Cavity Milling

Carbide long neck end mills excel in deep cavity milling. Their long neck design allows the tool to reach deep into the workpiece, accessing areas that standard tools cannot. In the mold-making industry, molds often require the machining of deep cavities and intricate internal features. Using them ensures stability and precision during the cutting process, resulting in high-quality surface finishes and accurate dimensions.

Complex Surface Processing

Components in the aerospace and automotive industries often have complex three-dimensional geometries, which demand high machining capabilities. Carbide long neck end mills can handle these complex surfaces with high precision, including curved surfaces, undercuts, and hard-to-reach areas. Their high rigidity and wear resistance allow them to maintain precision and consistency during the machining process, meeting the stringent surface quality and dimensional accuracy requirements of aerospace and automotive components.

High Wall and Deep Slot Machining

For parts requiring high wall or deep slot machining, carbide long neck end mills are an ideal solution. Their long neck design enables the tool to penetrate deep into the workpiece without interference from the tool holder, maintaining high precision and stability. This capability is particularly important when producing large parts or parts with complex geometries, significantly improving machining efficiency and quality.

Reduced Vibration and Chatter

The design of carbide long neck end mills effectively reduces vibration and chatter, common issues with long tools. Reduced vibration not only improves the surface finish of the machined parts but also extends the tool life. Vibration reduction helps enhance dimensional accuracy and surface quality, particularly in precision engineering applications.

Micro-Machining

In industries requiring high precision and small-sized components, such as medical device manufacturing, carbide long neck end mills are used for micro-machining tasks. These tools can produce fine details and maintain tight tolerances, making them ideal for manufacturing small and complex parts like surgical instruments and implants. Micro-machining demands high precision and stability within extremely small operational spaces, and they meet these requirements perfectly.

High-Speed Machining

Carbide long neck end mills are suitable for high-speed machining. Their material and design can withstand high cutting speeds and feed rates, enhancing production efficiency and machining speed. In the aerospace and automotive industries, high-speed machining helps shorten production cycles, improving the efficiency and quality of component manufacturing. The high wear resistance and thermal stability of carbide materials allow the tools to maintain stable performance under high-load conditions.

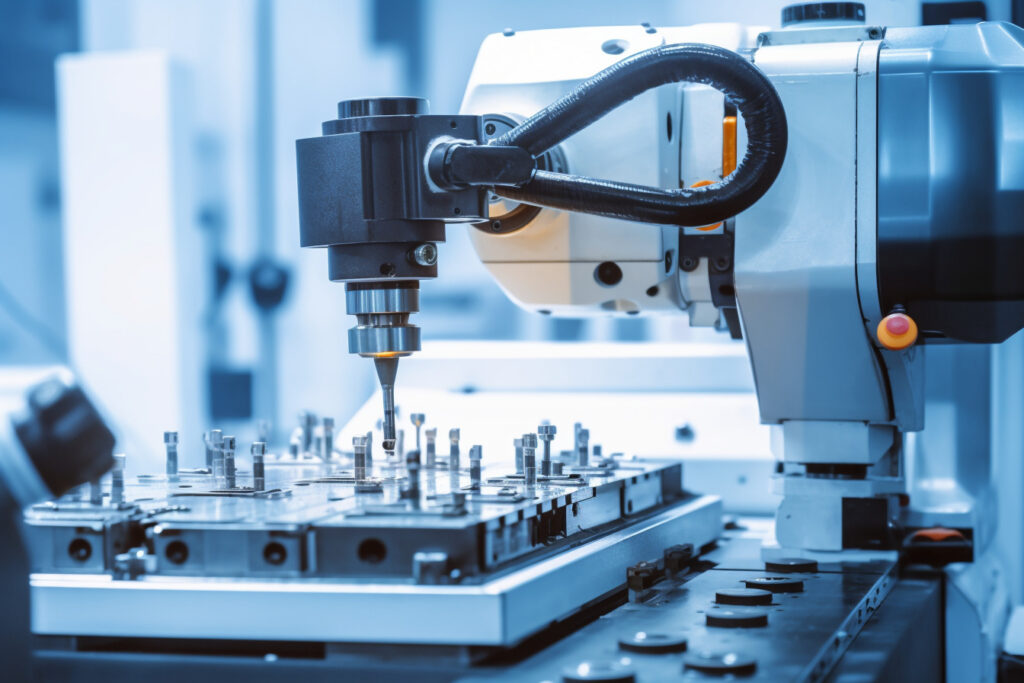

Multi-Axis Machining

In multi-axis CNC machining centers, carbide long neck end mills can perform complex angle and geometry machining. Multi-axis machining technology enables the tools to cut from different angles and directions, achieving efficient production of complex parts. The flexibility and high precision of them play a crucial role in multi-axis machining, reducing the number of setups and improving machining accuracy and efficiency.

Machining Various Materials

Carbide long neck end mills are suitable for machining various materials, including steel, aluminum, titanium, plastics, and composites. This versatility makes them widely used across multiple industries, from aerospace to consumer electronics and medical devices. Using the same tool to machine different materials reduces tool change time, increasing production efficiency. The high hardness and wear resistance of carbide materials allow the tools to maintain good cutting performance and long service life on different workpiece materials.

Conclusion

Carbide long neck end mills are indispensable tools in modern manufacturing. Their excellent performance in deep cavity, complex surface, and high-precision machining makes them widely used across various industries. With technological advancements and increasing manufacturing demands, the application range and importance of them continue to expand. Whether in deep cavity milling, complex surface processing, or high-speed applications, they stand out with their superior performance, driving innovation and efficiency in machining processes.