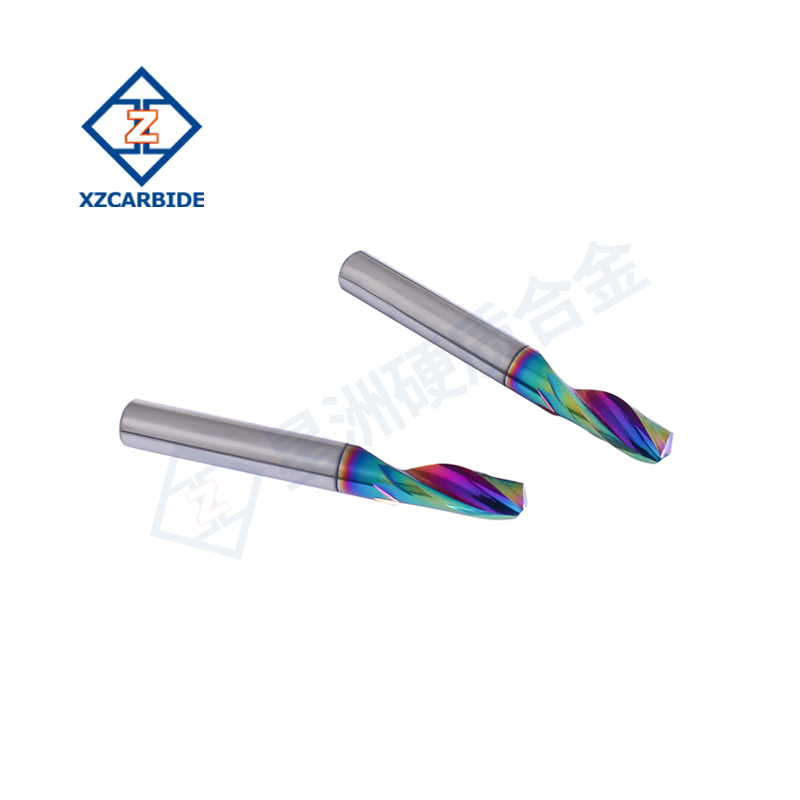

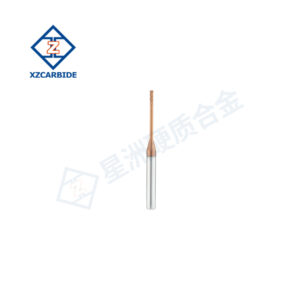

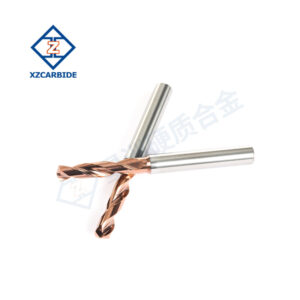

Product Features

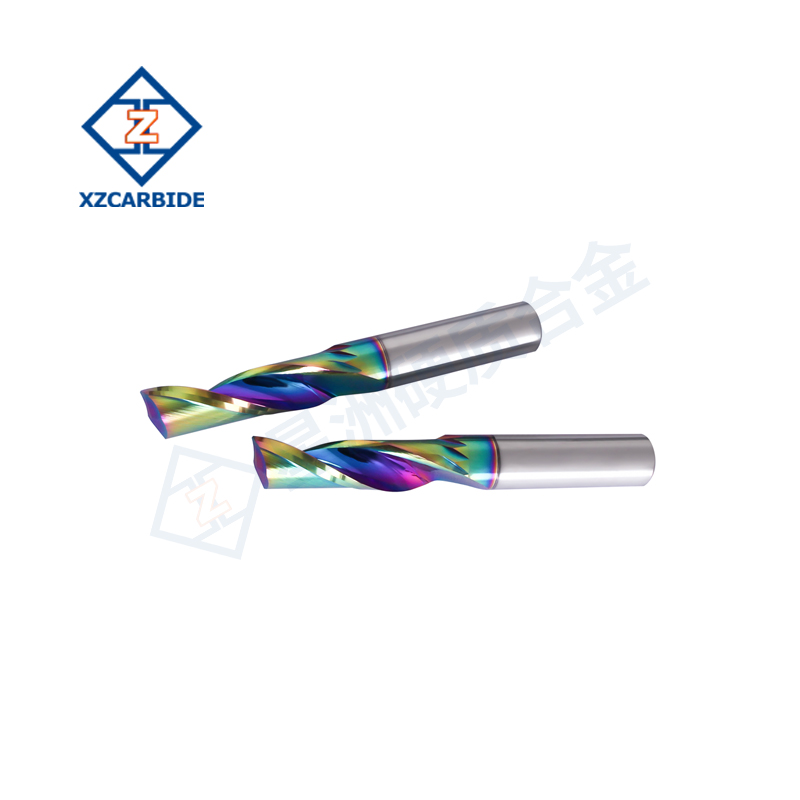

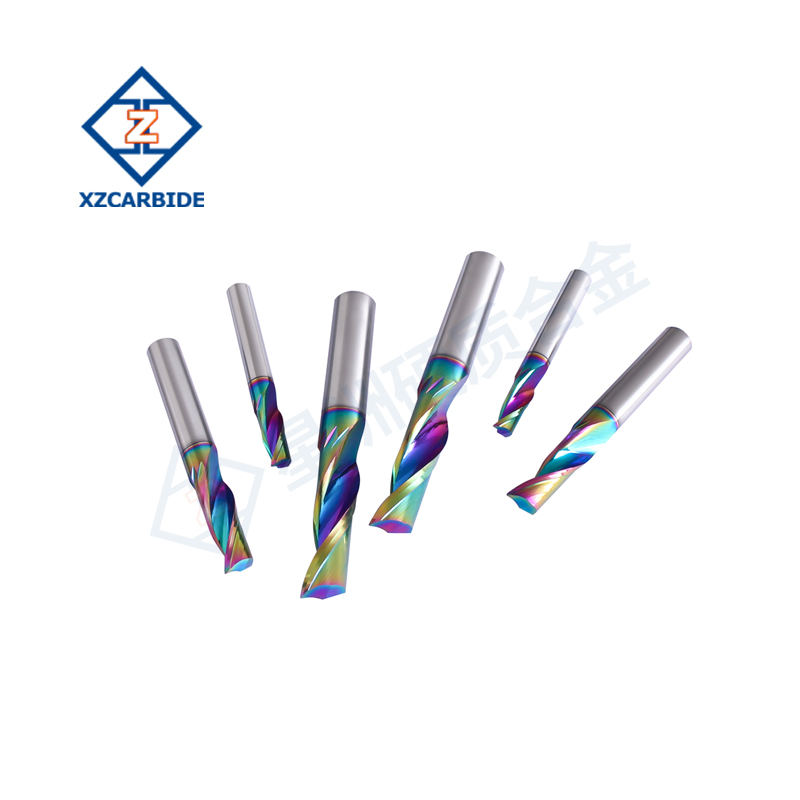

- Single-edged design: Single-edged milling cutter can cut fast, especially suitable for high-speed machining of aluminum and other non-ferrous metals, with excellent chip removal effect.

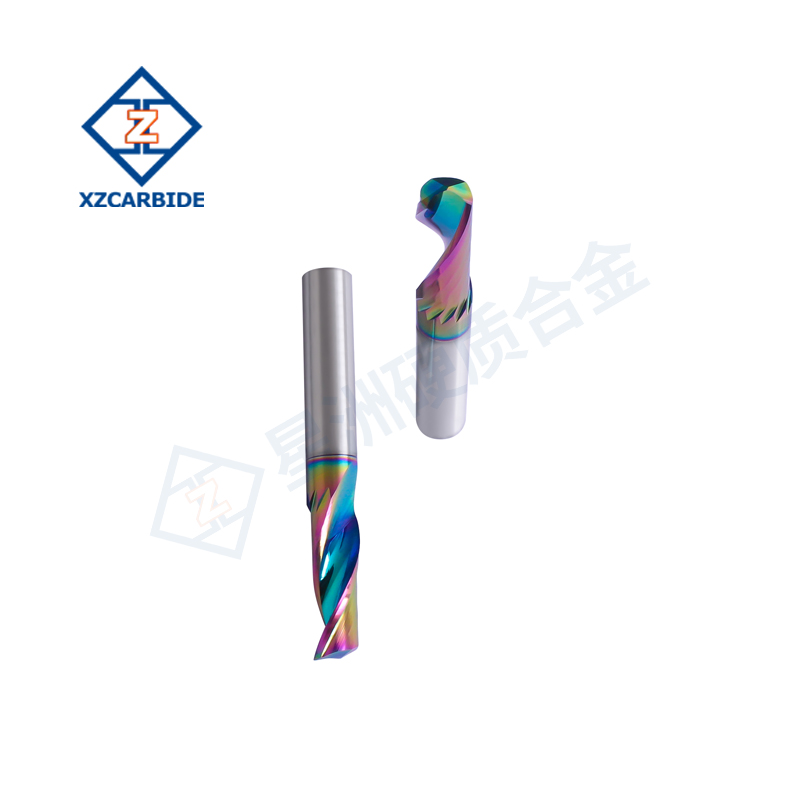

- Surface coating: High-quality coating increases the durability of the cutter, reduces the sticking phenomenon when machining aluminum, and prolongs the life of the cutter.

- Suitable for high speed cutting: Optimized tool geometries and coating combinations maintain excellent performance at high RPMs, especially for CNC machining centers.

- High cutting finish: The tool is precision designed and machined to achieve a high finish and reduce the need for secondary machining.

- Strong chip removal capacity: The single-edged structure makes chip removal smoother and is suitable for high volume machining of aluminum and other non-ferrous metals.

Applications

- Aluminum processing

- Non-ferrous metal machining, such as copper, brass, etc.

- CNC machining centers

- Mold manufacturing

- Precision machining in aerospace, automotive, electronics, etc.

Recommended Cutting Parameters

Cutting speed (aluminum): 500-1200 m/min

The optimum speed range for high-speed cutting of aluminum ensures a smooth surface finish and reduces tool wear.

Feed rate: 0.01-0.1 mm/tooth

The recommended range of feed speeds allows for optimal cutting results in different aluminum hardness.

Depth of cut: adjusted to process requirements

The tool is adapted to cutting operations at different depths, and shallow cutting is recommended to obtain higher surface accuracy.

Precautions for Use

- Ensure sufficient supply of coolant during cutting to minimize tool wear and overheating of the work piece surface.

- Adjust the rotational speed and feed rate reasonably to avoid excessive wear of the tool during high speed cutting.

- Clean and maintain the tool after use and store it properly to prolong its service life.

المراجعات

لا توجد مراجعات بعد.