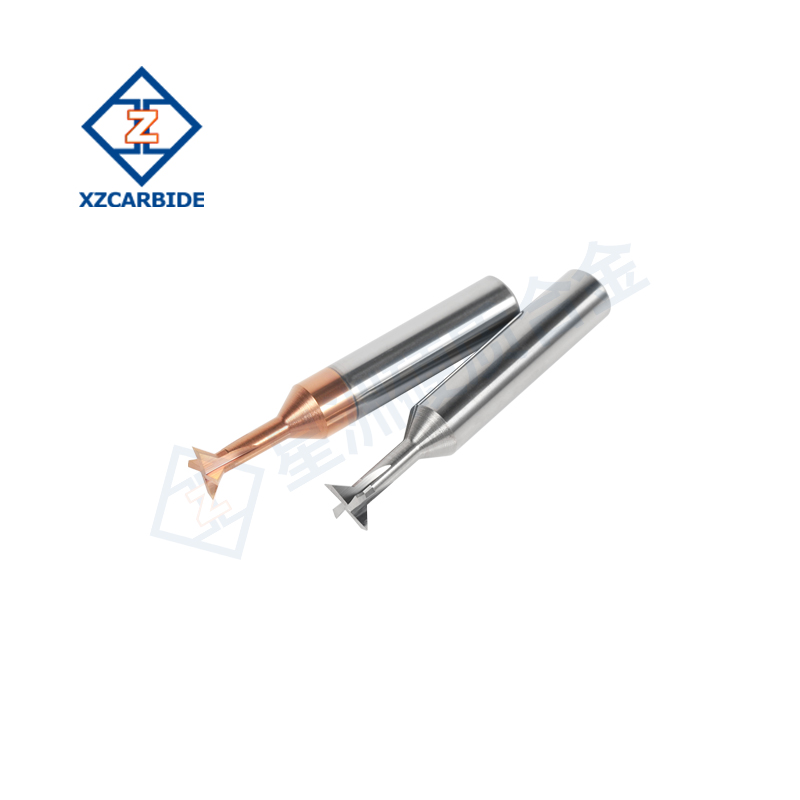

Main Features

- High precision machining: Capable of accurately machining dovetail grooves to specifications, ensuring high precision and high strength of workpiece assembly.

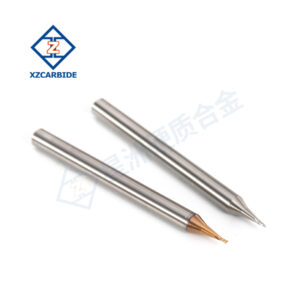

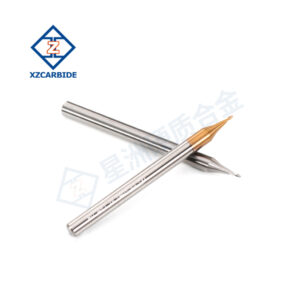

- High-quality materials: Made of high performance cemented carbide materials, with excellent wear resistance and impact resistance, prolonging the service life of the tool.

- High surface finish: The machined dovetail groove has a high surface finish, which reduces the subsequent machining process and improves the production efficiency.

- Multiple specification options: Provide different angles and sizes of dovetail end mills to meet various processing needs.

- Extensive application range: Suitable for dovetail groove machining of steel, stainless steel, aluminum alloy, titanium alloy and other materials.

Product Parameters

| Material | Tungsten carbide |

| Dovetail Angle | 30°,45°, 60°, 75°, etc. |

| Tool Diameter | 3-20 mm |

| Tool Length | 50-150 mm |

| Number of Flute | 2 flutes, 4 flutes |

| Coating | TiN、TiAlN、DLC and others |

Application Scenarios

- Aerospace: Used for processing high-precision and high-strength aviation parts.

- Automobile Manufacturing: Play an important role in the precision processing of automobile parts.

- Mold Manufacturing: Processing high-precision molds to ensure the accuracy and durability of the molds.

- Electronic Communication: For precision electronic component shell and internal structure processing.

المراجعات

لا توجد مراجعات بعد.