Custom carbide strips are suitable for many complex machining environments due to their high hardness, wear resistance and precise manufacturing processes.

Product Features

- High hardness: The hardness of the carbide strips is much higher than ordinary steel, which can easily cut all kinds of hard materials.

- Excellent abrasion resistance: Carbide strips can remain sharp during long time use, reducing the frequency of replacement.

- Good thermal stability: The performance can still be maintained under high temperature environment, suitable for high-speed cutting.

Customized Services

We offer comprehensive customization services, including:

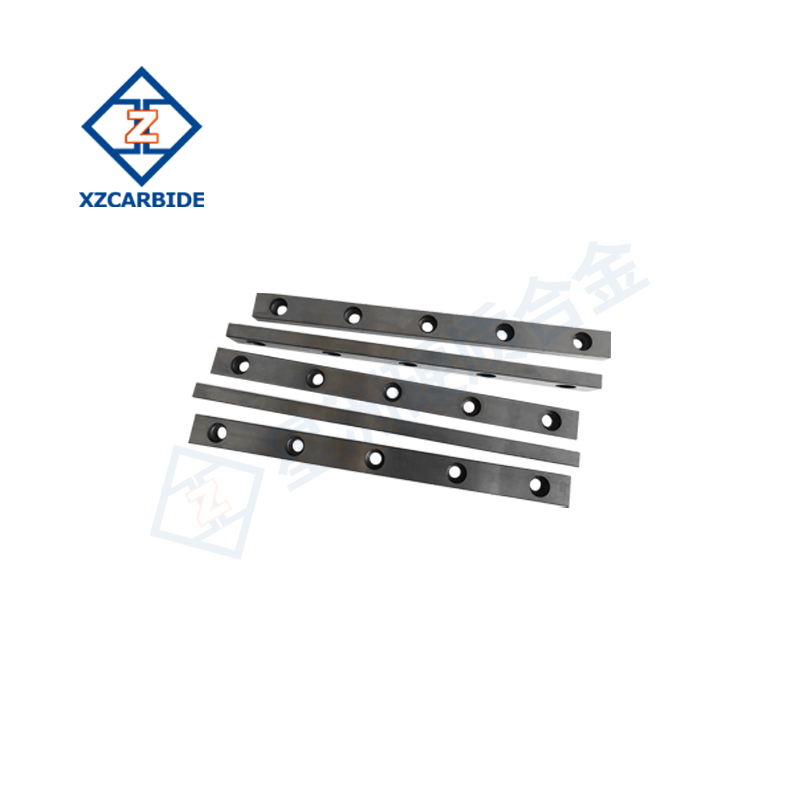

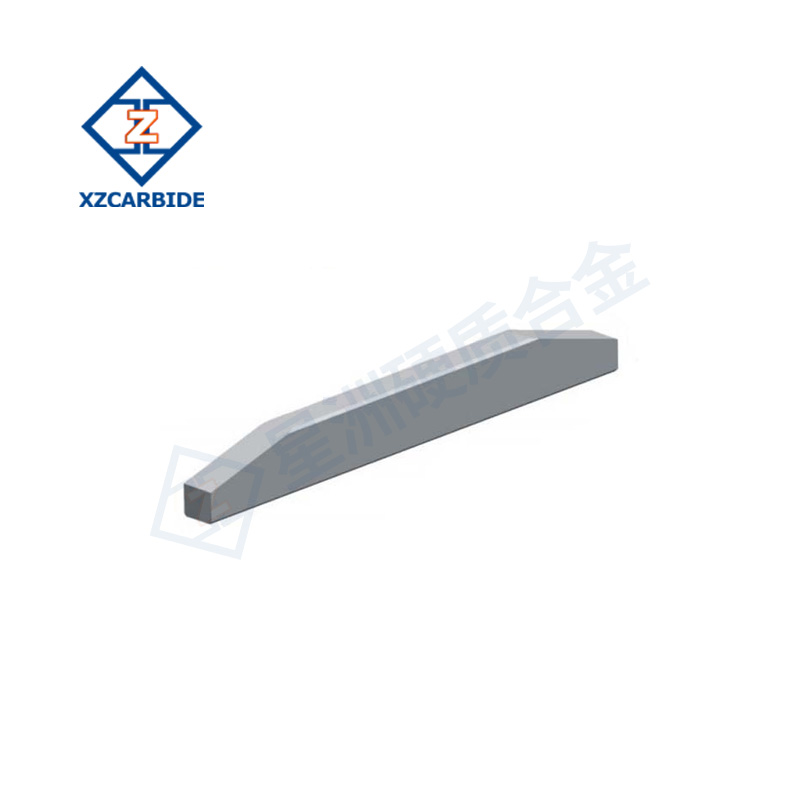

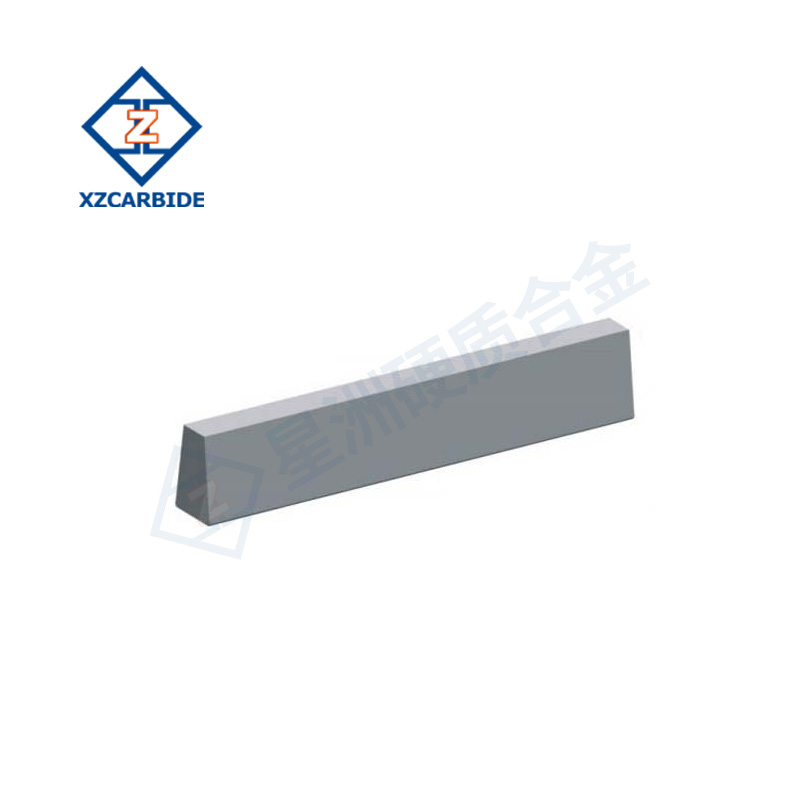

- Size customization: Carbide strips are available in different lengths, widths and thicknesses according to customer requirements.

- Shape customization: In addition to standard rectangles, special shapes can also be customized.

- Material customization: Different grades of carbide materials are selected according to the usage environment and requirements.

Common Used Grades

| Grade | International Standards | Density (g/cm3) | Hardness (HRA) | Bending Strength (MPa) | Scope of Application |

YG8 | K30 | 14.8 | 89.5 | ≥3500 | High strength, impact resistance and shock resistance, better than YG6. Suitable for making forming knives and wear-resistant parts. |

YG11 | K40 | 14.4 | 88.5 | ≥3650 | Suitable for making stamping molds. |

NT15 | K40 | 14.0 | 87.5 | ≥3800 | Suitable for making stamping dies (processing silicon steel sheets), wear-resistant parts, etc. |

YG20 | K30 | 13.5 | 85.5 | ≥4200 | High strength, suitable for making progressive dies and other stamping dies. |

YG6X | K10 | 14.9 | 91.5 | ≥3200 | Fine-grained alloy with good wear resistance and is suitable for making forming knives and wear-resistant parts. |

YL10.2 | K10 | 14.5 | 92 | ≥3850 | Ultra-fine grain alloy with high wear resistance, bending strength, anti-adhesion ability and pad strength. It is suitable for low-speed rough machining. |

Other grades are available on request | |||||

المراجعات

لا توجد مراجعات بعد.