Product Features

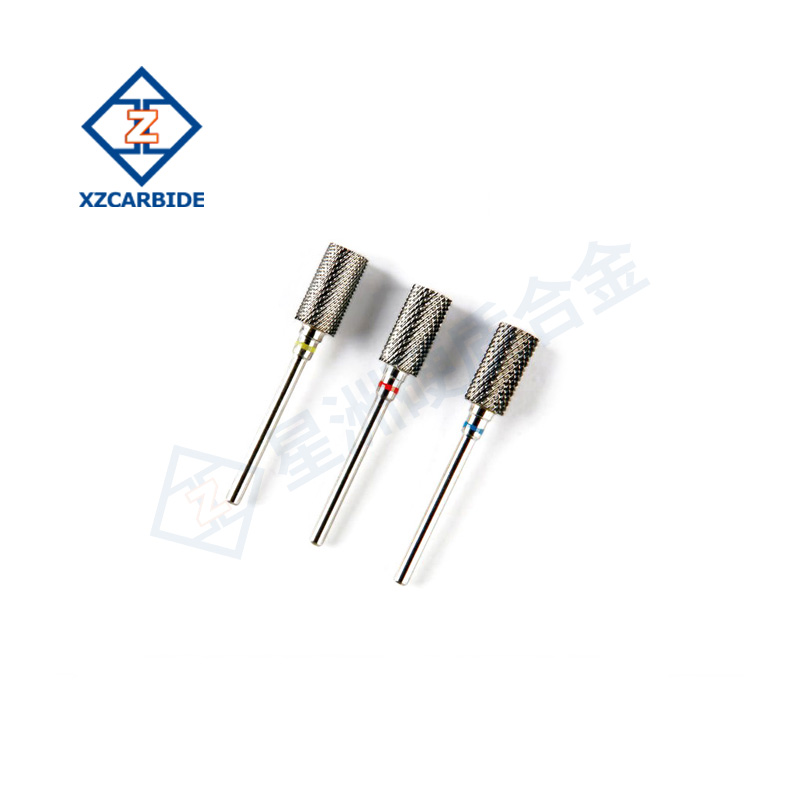

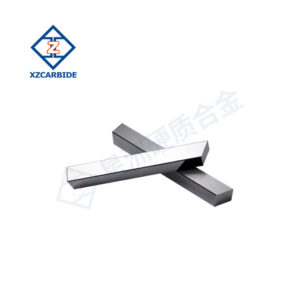

- High hardness and wear resistance: The tungsten carbide material gives the rotary burr extremely high hardness and wear resistance, enabling it to easily cope with a wide range of hard materials while maintaining sharpness for a long time.

- Various shapes and sizes: In order to meet different machining needs, tungsten carbide rotary burr provides several shapes (e.g. cylindrical, spherical, conical, flame, etc.) and sizes to choose from, which ensures that the user can find the tool that best suits their machining tasks.

- Efficient machining: Due to the excellent performance of tungsten carbide rotary burrs, it can significantly improve machining efficiency, reduce machining time and lower production costs.

- Precision machining: Tungsten carbide rotary burrs are capable of fine machining to meet occasions requiring high machining accuracy.

Types

Applications

Tungsten carbide rotary burrs are widely used in the following fields:

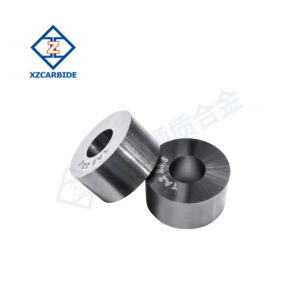

- Metal processing: including the processing of iron, steel, stainless steel, alloy steel and many other metal materials.

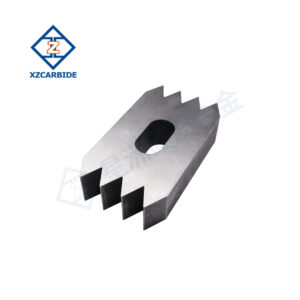

- Machinery manufacturing: Used for metal removal, deburring, slotting and other operations during the manufacturing and maintenance of mechanical equipment.

- Mold making: In the process of mold making, it is used to carve and polish the surface of the mold to improve the precision and service life of the mold.

- Aerospace: In the aerospace field, tungsten carbide rotary burrs are used in the processing and repair of precision parts.

- Automobile production: In the process of automobile manufacturing, it is used for the processing and deburring of engine blocks, crankshafts and other components.

المراجعات

لا توجد مراجعات بعد.