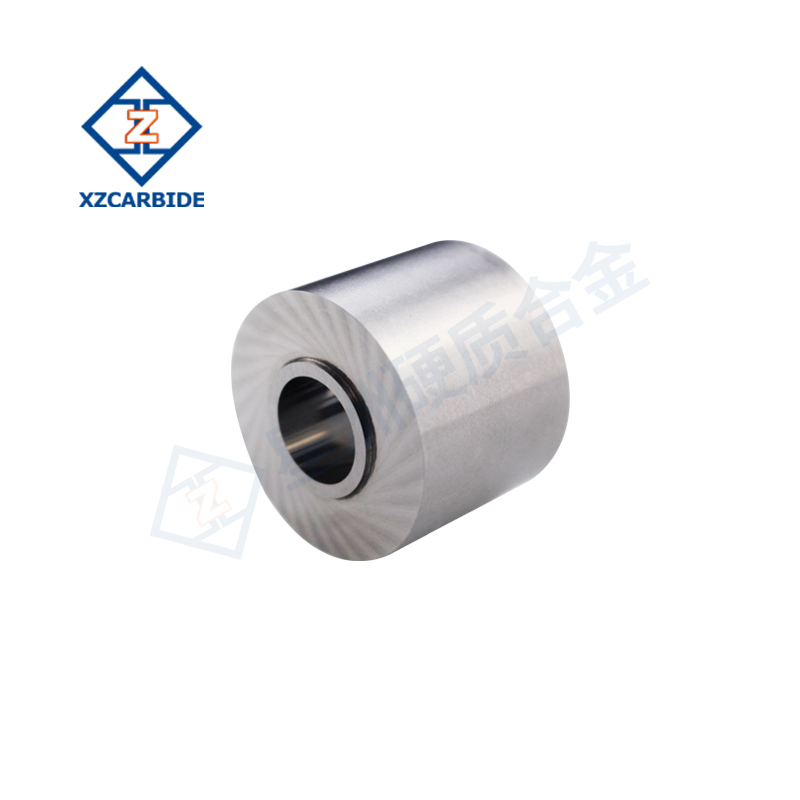

Technical Parameters

| Material | Tungsten carbide |

| Hardness | HRA 85-92 |

| Density | 13.8-14.9 g/cm3 |

| Surface Roughness | Ra 0.2 μm or less |

| Stamping Times | Up to 1,000,000 cycles or more (depending on specific operating conditions) |

| Size | Can be customized |

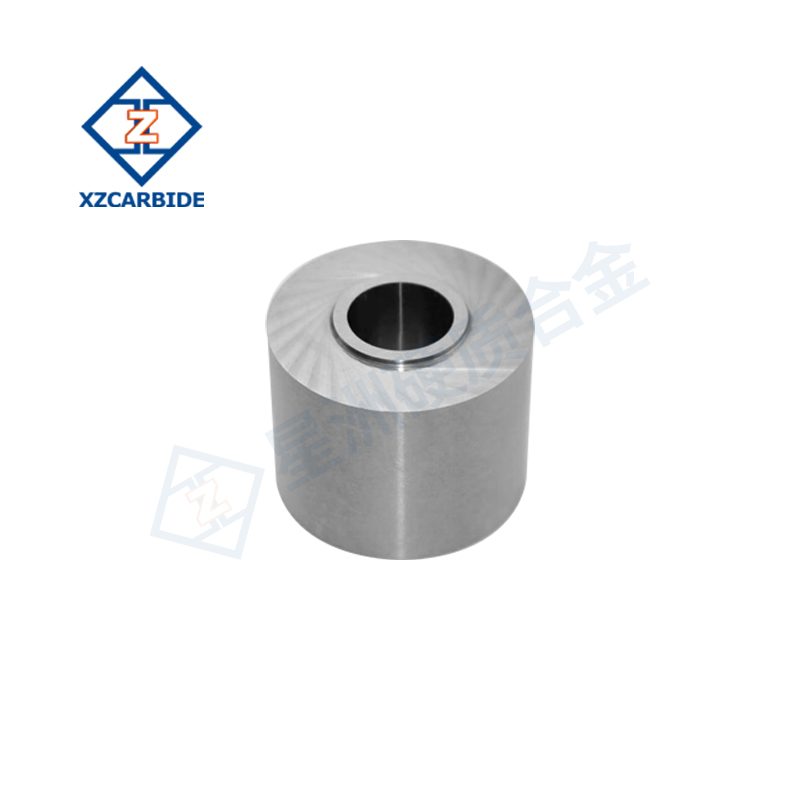

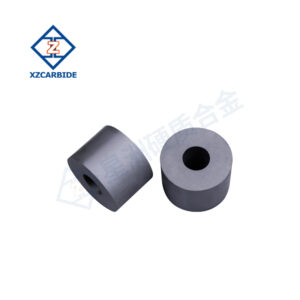

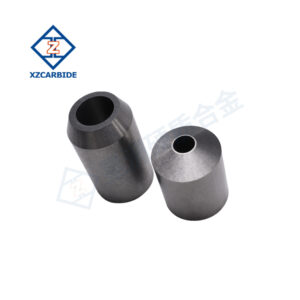

Product Features

- High abrasion resistance: Effectively resist wear and tear in the high-intensity punching process, prolonging the service life of the mold.

- High hardness: Able to withstand high-pressure and high-frequency impact to ensure molding quality.

- Impact resistance: Maintain stable mechanical properties in the process of high-intensity punching, it is not easy to break.

- Precision processing: Adopt advanced processing technology to ensure the dimensional accuracy and surface finish of the mold.

- High-temperature resistance: Suitable for high-temperature punching environment to ensure that the mold is not deformed and has stable performance.

- Customized service: Provide customized service, design and manufacture punching dies of different sizes, shapes and carbide grades according to customers’ needs.

Common Used Grades

| Grade | Density (g/cm3) | Hardness (HRA) | TRS (N/mm2) |

| YG6 | 14.7~15.1 | 89.5 | 1520 |

| YG8 | 14.6~14.9 | 89 | 1670 |

| YG11 | 14.3~14.8 | 88 | 1860 |

| YG15 | 13.9~14.2 | 86.5 | 2060 |

| YG20 | 13.4~13.8 | 83.5 | 2480 |

| YG20C | 13.4~13.8 | 82 | 2480 |

| YG25 | 13.2~13.6 | 80 | 2600 |

| YL10.2 | 14.5~14.8 | 90 | 2400 |

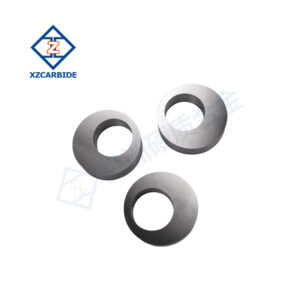

Application Areas

Carbide punching dies are widely used in the following fields:

- Automobile manufacturing: Used for punching and manufacturing automobile parts to ensure high precision and quality products.

- Electronics industry: Suitable for the production of various electronic components to meet the needs of high precision and high output.

- Aerospace: When manufacturing aviation spacecraft parts, carbide dies can ensure high precision and durability of the parts and adapt to the harsh working environment.

- Home appliance manufacturing: Used in the punching production of various types of home appliance parts, improving production efficiency and product consistency.

- Medical devices: When manufacturing precision medical device parts, carbide dies provide excellent precision and durability, ensuring that products meet high standards of medical requirements.

المراجعات

لا توجد مراجعات بعد.