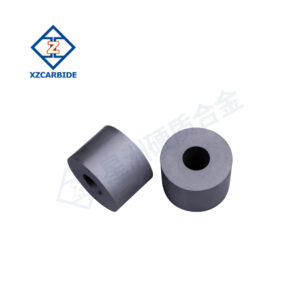

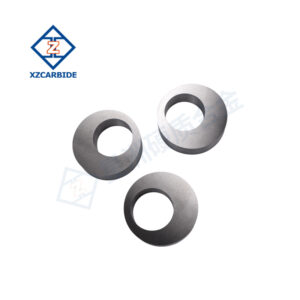

Technical Parameter

| Material | The main components are tungsten carbide and other metal carbides with cobalt binder. |

| Hardness | 92.0 HRA |

| Density | 14.0-14.5 g/cm³ |

| Grain Size | 0.6 μm |

| Bending Strength | 4000 MPa |

| Modulus of Elasticity | 490 Gpa |

| Coefficient of Thermal Expansion(CTE) | 5.4×10^-6/°C |

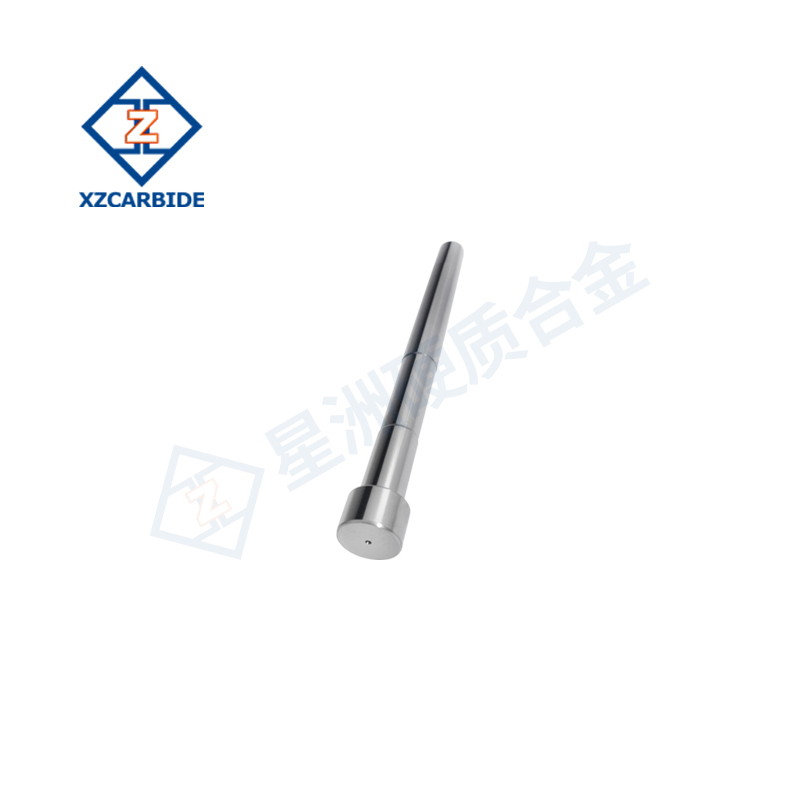

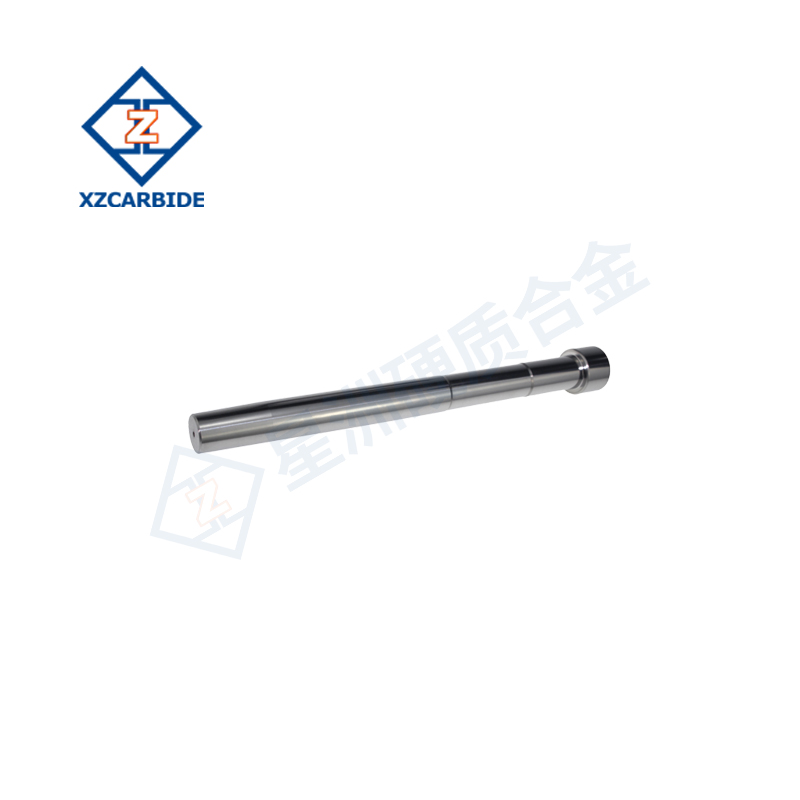

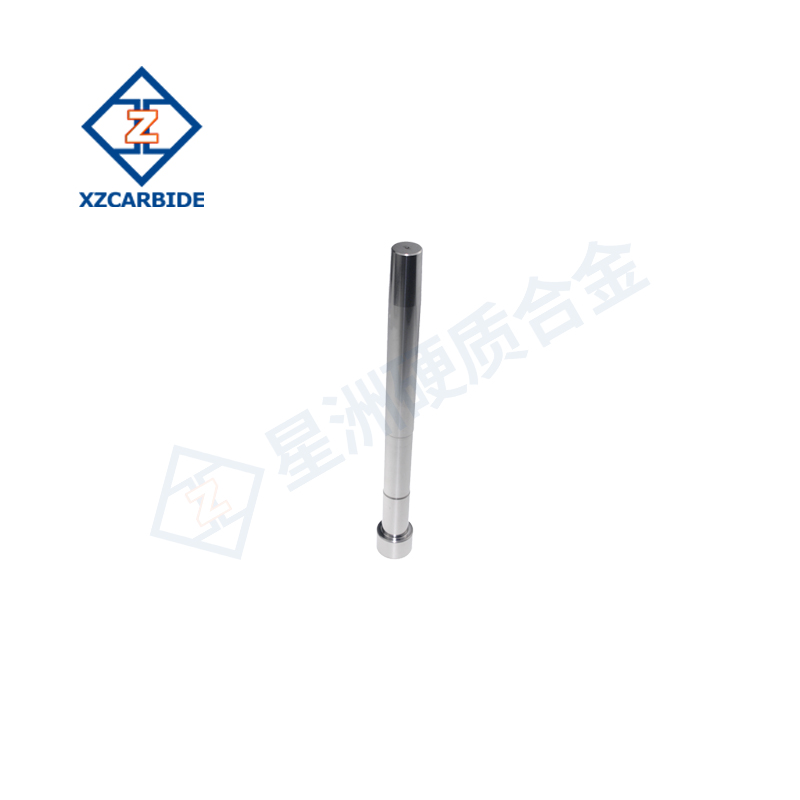

Main Features

- High hardness: Using high quality alloy steel or cemented carbide material, it has very high hardness and can keep sharp for a long time.

- High precision: Precision manufacturing process ensures that the dimensions and form tolerances of the punching needles meet the strict requirements to guarantee the processing quality.

- Strong abrasion resistance: Excellent abrasion resistance, prolonging the service life and reducing the frequency of replacement.

- Multi-specification options: Provide a variety of specifications and sizes to meet different molds and processing needs.

- Surface treatment: After special surface treatment to enhance corrosion resistance, suitable for various working environments.

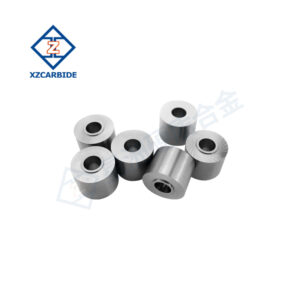

Applications

- Electronics industry: Punching and molding of precision electronic components.

- Automobile manufacturing: Punching and molding of car body and parts.

- Home appliance manufacturing: Punching and molding of home appliance shells and parts.

- Aerospace: High precision punching of aircraft parts.

- Hardware and electromechanical: Used in punching dies to achieve separation or plastic deformation of materials.

- Mold Manufacturing: As precision mold parts to improve the durability and stability of the mold.

- Industrial machinery: Used for wear-resistant parts in machining.

المراجعات

لا توجد مراجعات بعد.