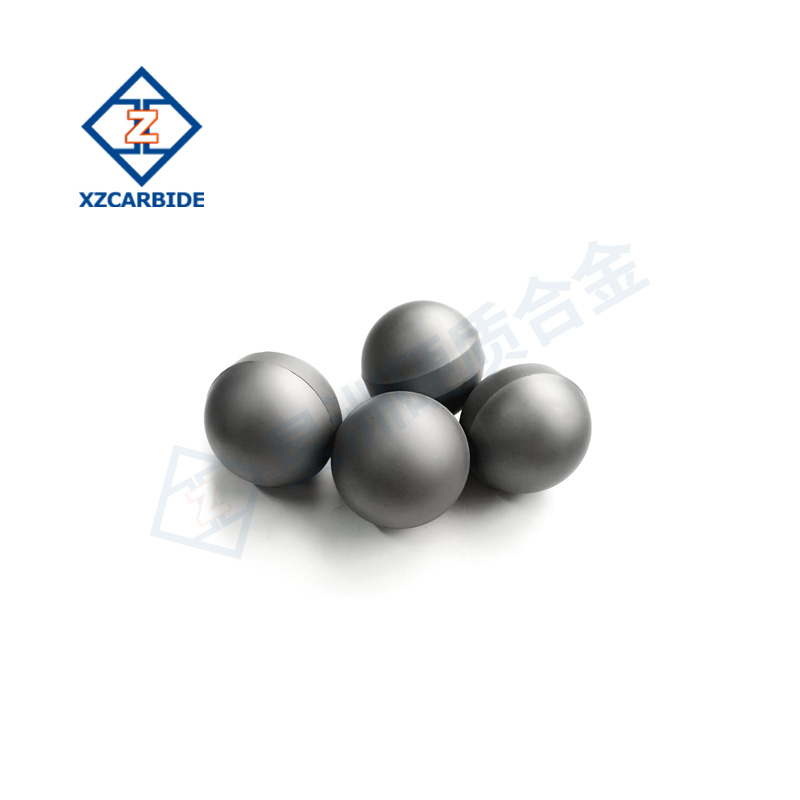

Main Features

- High hardness: Cemented carbide materials give the balls extremely high hardness, ensuring excellent performance under high load and high wear environments.

- Strong abrasion resistance: Excellent abrasion resistance makes it possible to maintain precision and surface finish after a long period of use.

- Corrosion resistance: Good corrosion resistance, suitable for a variety of harsh environments.

- High precision: Adopt precision manufacturing process to ensure the dimensional accuracy and roundness of the ball to meet the needs of high-precision applications.

- Multi-specification options: Provide various specifications and sizes to meet different application requirements.

Carbide Ball Specifications

Nominal Diameter | |||||

mm | inch | mm | inch | mm | inch |

0.5 | 5 | 11.113 | 7/16 | ||

0.6 | 5.159 | 13/64 | 12 | ||

| 0.794 | 1/32 | 5.5 | 12.303 | 31/64 | |

0.8 | 5.953 | 15/64 | 12.7 | 1/2 | |

1 | 6 | 13.494 | 17/32 | ||

| 1.588 | 1/16 | 6.35 | 1/4 | 14.288 | 9/16 |

2 | 6.5 | 15 | |||

2.381 | 3/32 | 6.747 | 17/64 | 16 | |

| 2.5 | 7 | 16.669 | 21/32 | ||

2.778 | 7/64 | 7.144 | 9/32 | 18.256 | 23/32 |

3 | 7.5 | 19.844 | 25/32 | ||

3.175 | 1/8 | 7.938 | 5/16 | 20.638 | 13/16 |

3.5 | 8 | 22.225 | 7/8 | ||

3.969 | 5/32 | 8.5 | 28.575 | 1 1/8 | |

4 | 9 | 30.162 | 1 3/16 | ||

| 4.5 | 9.525 | 3/8 | |||

| 4.763 | 3/16 | 10 | |||

Note: The special specification can be manufactured after negotiating.

Applications

- Precision bearings: Used to improve the wear resistance and load carrying capacity of bearings.

- Instrumentation: Used as moving parts in precision instruments.

- Pen industry: Used as the ball of high-end pens to provide a smooth writing experience.

- Spraying equipment: Used as a key wear-resistant component in spraying machines.

- Mechanical parts: Used in mechanical parts that require wear resistance and stability.

- Sealed valves: Used in valves that require high sealing performance.

- Grinding media: Used as highly efficient grinding media in grinding and polishing processes.

المراجعات

لا توجد مراجعات بعد.