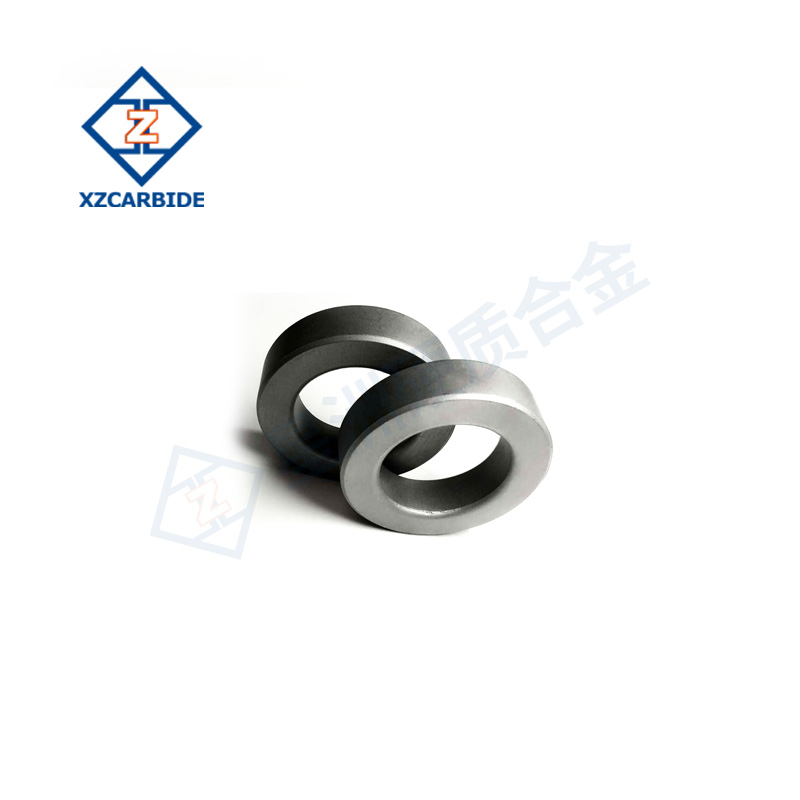

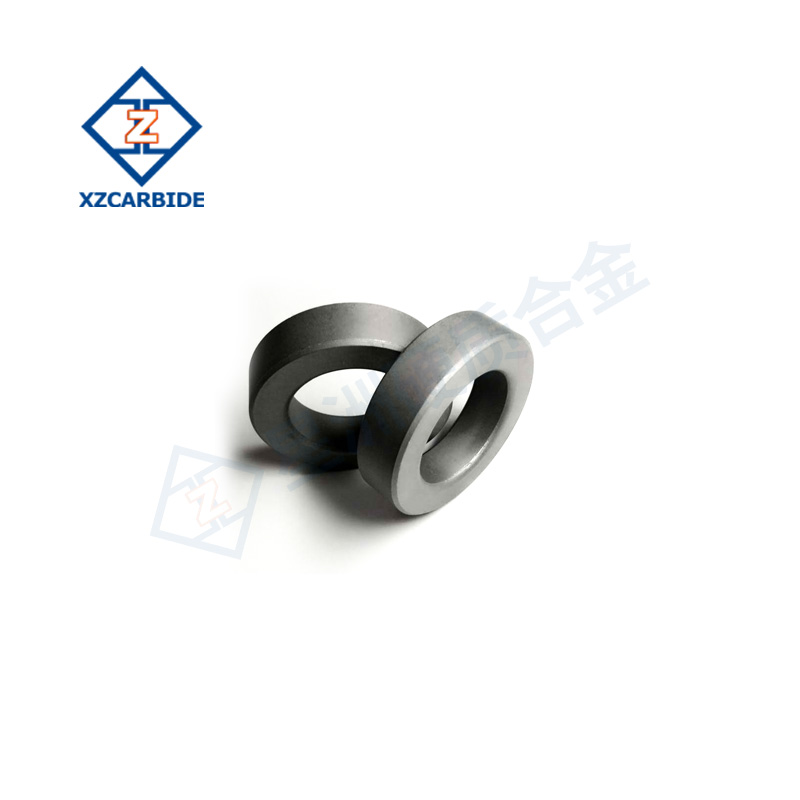

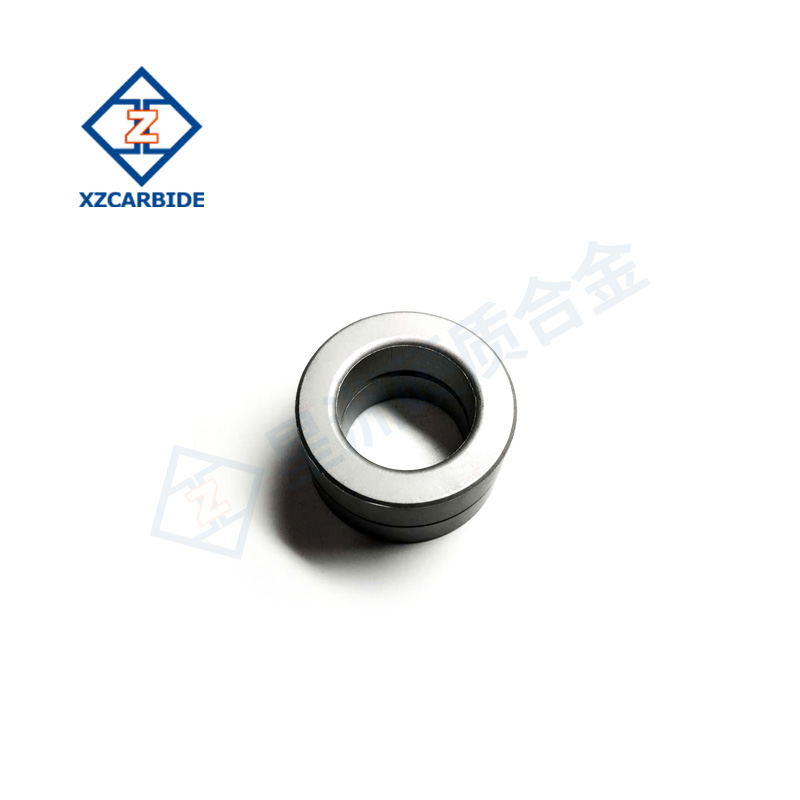

Product Features

- High strength and abrasion resistance: The combination of tungsten carbide and metal gives the ball valve seat extremely high hardness and abrasion resistance, which can resist the impact and abrasion of high-pressure, high-speed fluids and solid particles, and extend the service life of the valve.

- Excellent corrosion resistance: Good chemical stability makes the ball valve seat able to resist the erosion of acid, alkali and other corrosive media, adapting to many complex working conditions.

- High-precision processing: The ball valve seat is precisely ground and processed to ensure that the sealing surface between the ball valve and the ball valve to achieve extremely high matching accuracy, and realize the operating experience of low torque and high sealing performance.

- High-temperature stability: In high-temperature environments, the carbide ball valve seat can still maintain stable physical and chemical properties, and will not fail due to thermal expansion or thermal stress.

- Bidirectional sealing: Unique structural design makes the cemented carbide ball valve seat has bidirectional sealing function, no matter how the fluid flow direction changes, it can ensure the sealing effect and improve the safety and reliability of the system.

Technical Parameters

| Material | High quality tungsten carbide |

| Hardness | HRA 85~92 |

| Size | Customize by drawing |

| Working Temperature | -50°C~300°C |

| Sealing Performance | Low or even no leakage |

Applications

- Oil drilling, deep sea drilling and other high-pressure, highly corrosive environments

- Fluid control systems in the chemical and metallurgical industries

- Valve systems that require high wear and corrosion resistance

- Piping systems that require high sealing performance

المراجعات

لا توجد مراجعات بعد.