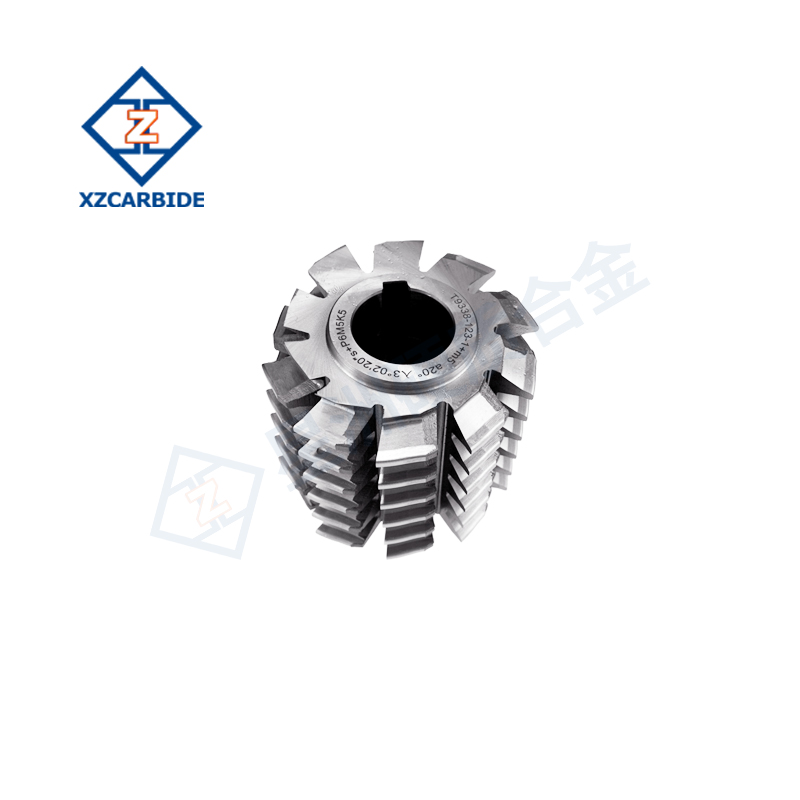

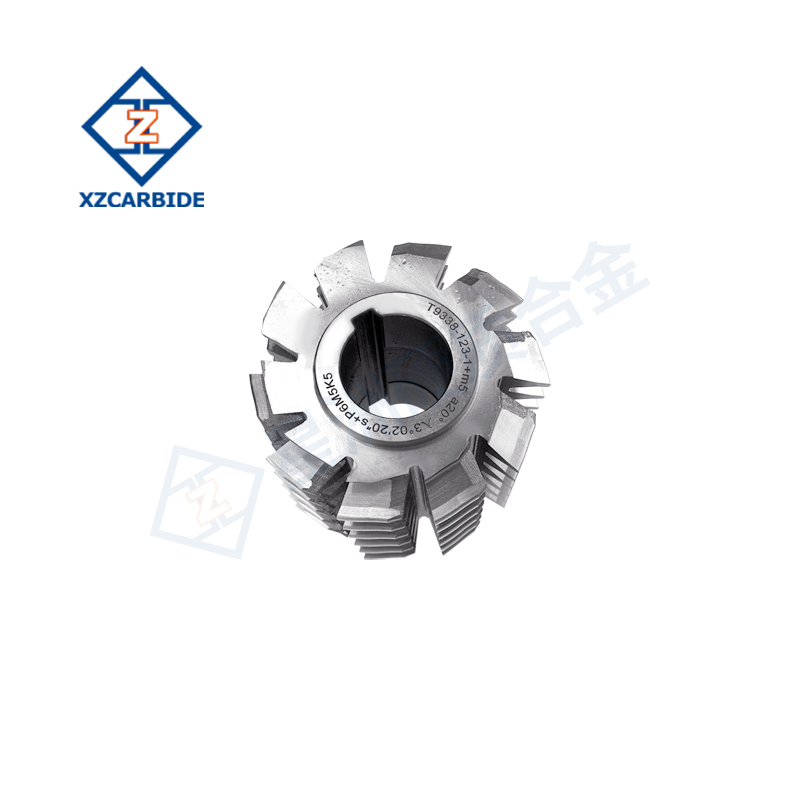

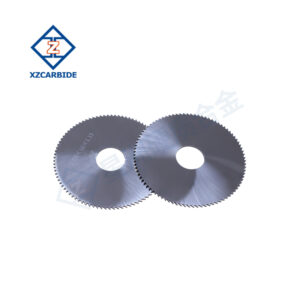

Main Features

- High precision: Adopting advanced manufacturing process to ensure the accuracy of each tooth shape and guarantee the precision of machining gears.

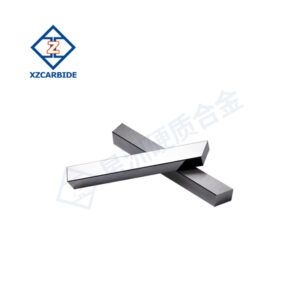

- High hardness: Selection of high-quality high-speed steel or hard alloy material, with extremely high hardness and wear resistance, prolonging tool life.

- High efficiency: Special tool design improves cutting efficiency, reduces machining time and increases productivity.

- Multi-specification options: Provide a variety of specifications and sizes to meet different gear and spline machining needs.

- Strong heat resistance: With excellent heat resistance, it can work stably in high temperature environment.

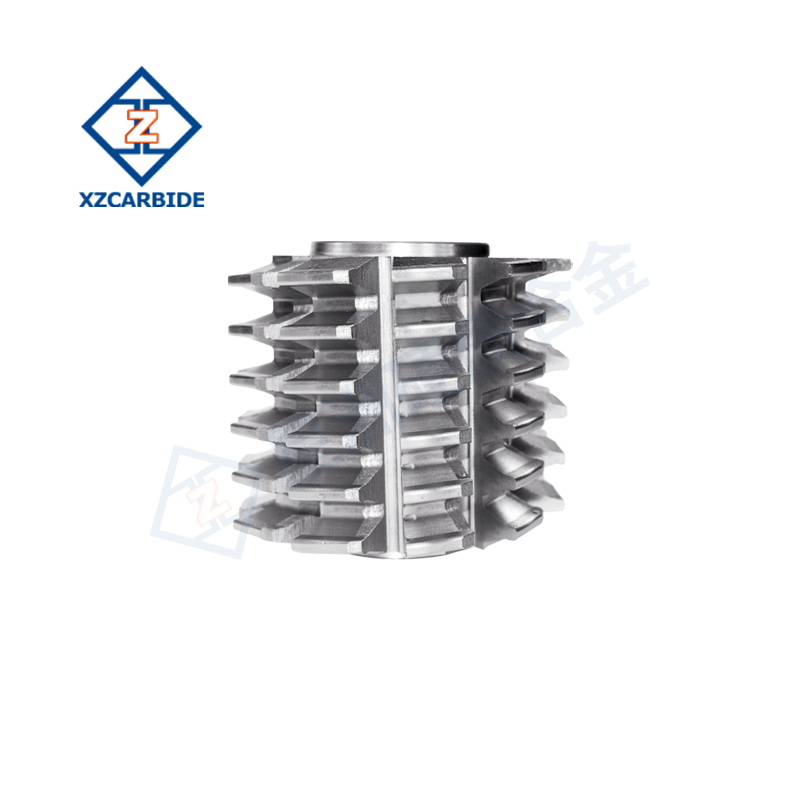

Working Principle

The working principle of the hob is to rely on the cutting edge and expanding edge to rotate and oscillate continuously on the surface of the metal material, cutting the metal material to form the required shape and size. The cutting edge is the key part of the hob, which is divided into two kinds: positive spiral cutting edge and negative spiral cutting edge, which are suitable for machining metal parts with high precision and high strength respectively. The expanding edge is used to remove burrs and residual material produced after the cutting edge is removed.

Regular Size (Support Customization)

|

Module (mm) |

Outside Diameter

(mm) |

Hole Diameter (mm) |

|

0.15 |

25 | 8 |

| 0.30 | 25 |

8 |

|

0.60 |

25 | 8 |

| 0.80 | 25 |

8 |

|

0.9 |

32 | 13 |

| 1.0 | 32 |

13 |

المراجعات

لا توجد مراجعات بعد.