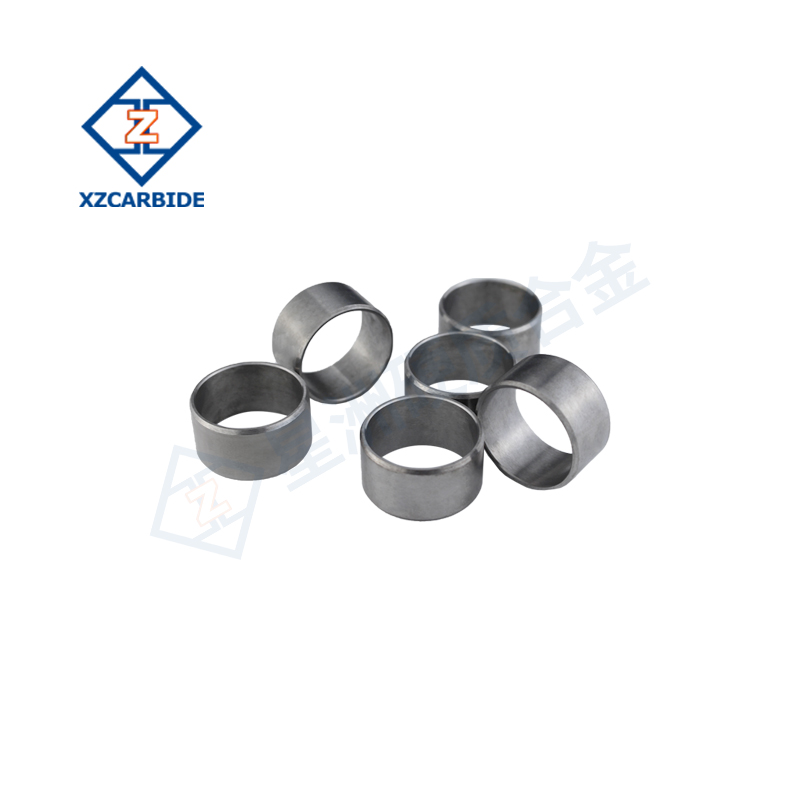

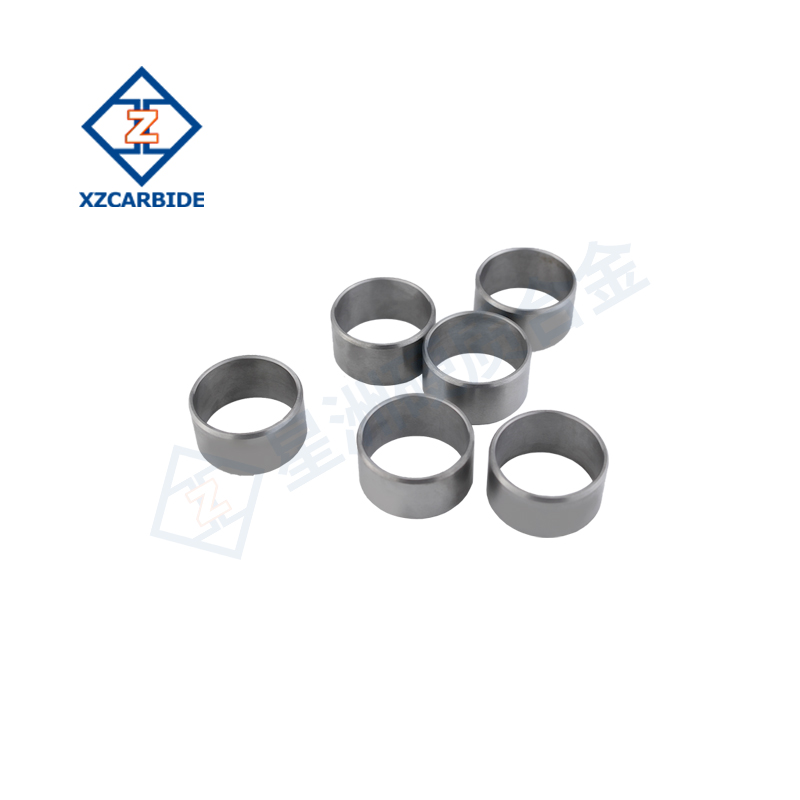

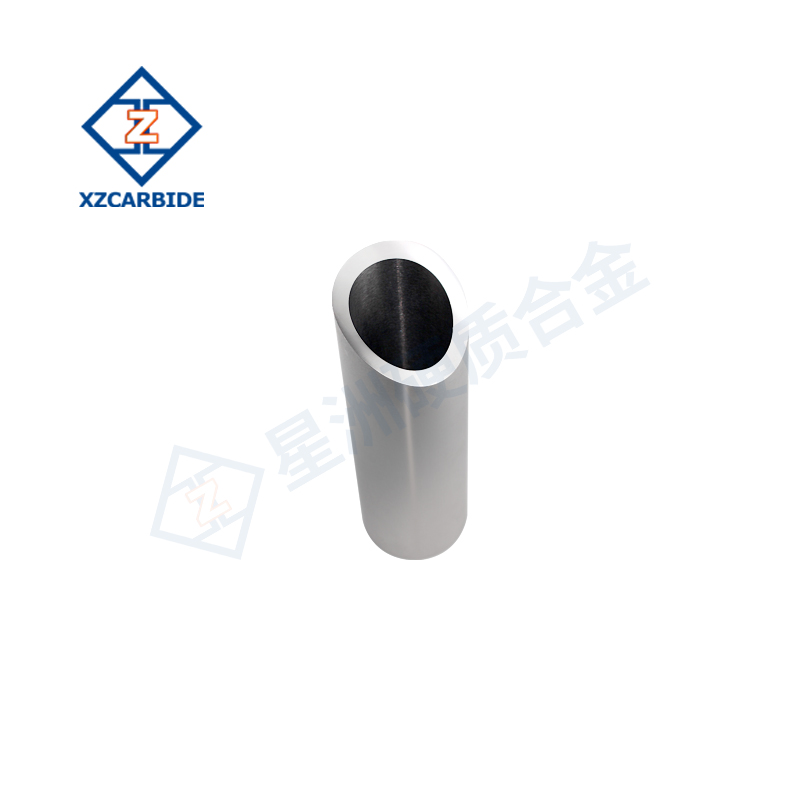

Basic Info.

| Material | Tungsten carbide |

| Common Grades | YG series |

| Hardness | HRA 89-92 |

| Compressive Strength | >4000 MPa |

| Dimensions | Inner Diameter: 10 mm to 200 mm Outer Diameter: 20 mm to 300 mm Height: 20 mm to 150 mm |

| Features | High hardness Superior wear resistance Strong stability High corrosion resistance |

| Adavantages | Reduced maintenance costs Increased production efficiency Extended equipment lifespan |

| Applications | Automotive, aerospace, industrial equipment |

Common Used Grades

| Grade | Composition | Density (g/cm3) | Hardness (HRA) | Flexural Strength (MPa) | Properties |

| YG6 | 94% WC, 6% Co | 14.6 | 89 | 1520 | High hardness and good wear resistance , suitable for general wear and impact applications. |

| YG8 | 92% WC, 8% Co | 14.5 | 88.5 | 1600 | High hardness with impact resistance , suitable for medium impact and wear conditions. |

| YG15 | 85% WC, 15% Co | 14.0 | 86 | 2400 | High flexural strength and impact toughness , ideal for high impact and wear environments. |

| YG20 | 80% WC, 20% Co | 14.0 | 84 | 2800 | Extremely high flexural strength and toughness , ideal for high impact and high wear environments. |

Quality Control

- All raw materials are tested for density, hardness and TRS before use;

- Each product undergoes process and final inspection;

- Every batch of products can be traced.

المراجعات

لا توجد مراجعات بعد.